DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual Section 11 revised Jan 2021

2.4 DISASSEMBLY, REASSEMBLY,

ADJUSTMENT AND TORQUE CHART

Disassembly and re-assembly procedures are

covered in the following manual:

• ZF AXLE A132 REPAIR MANUAL #5871 207 002E

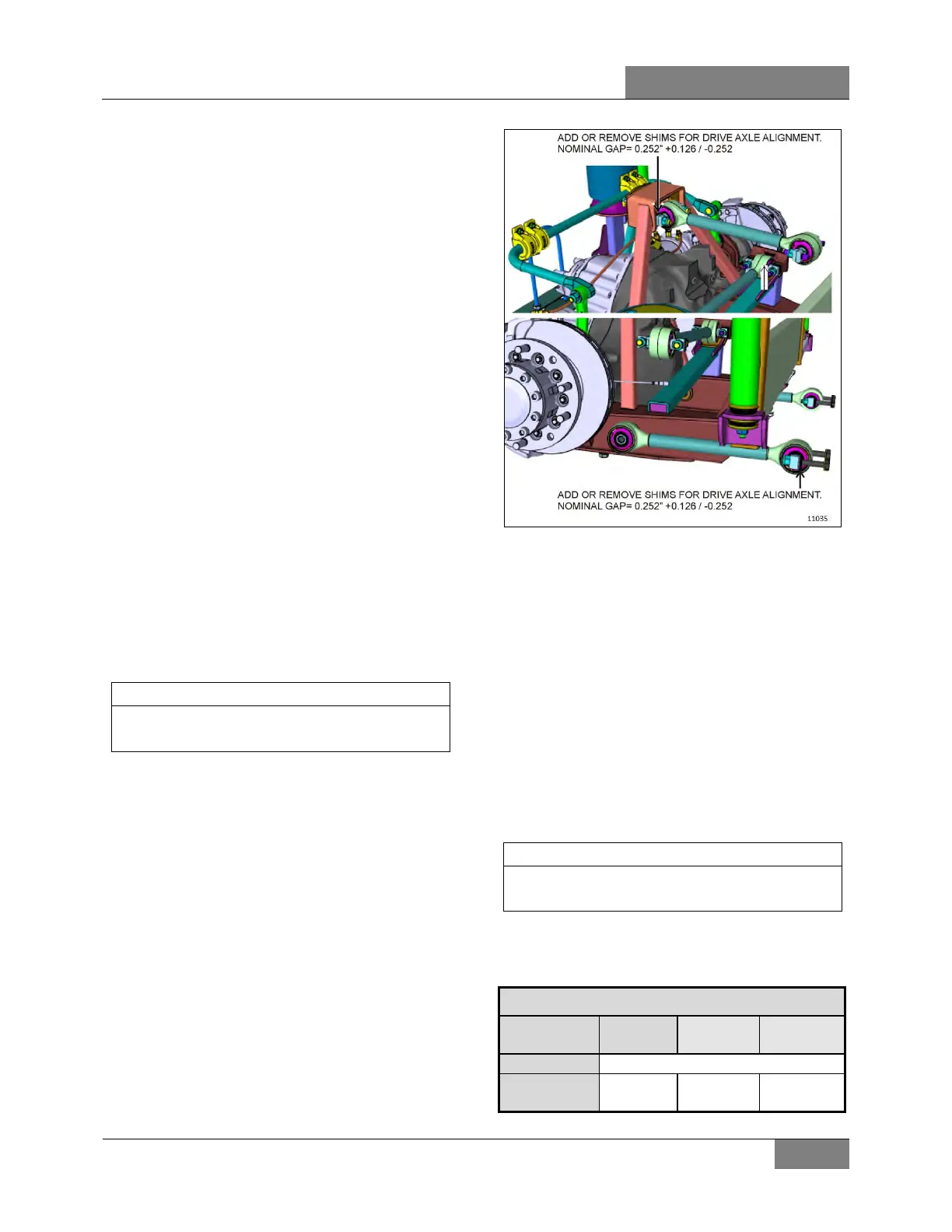

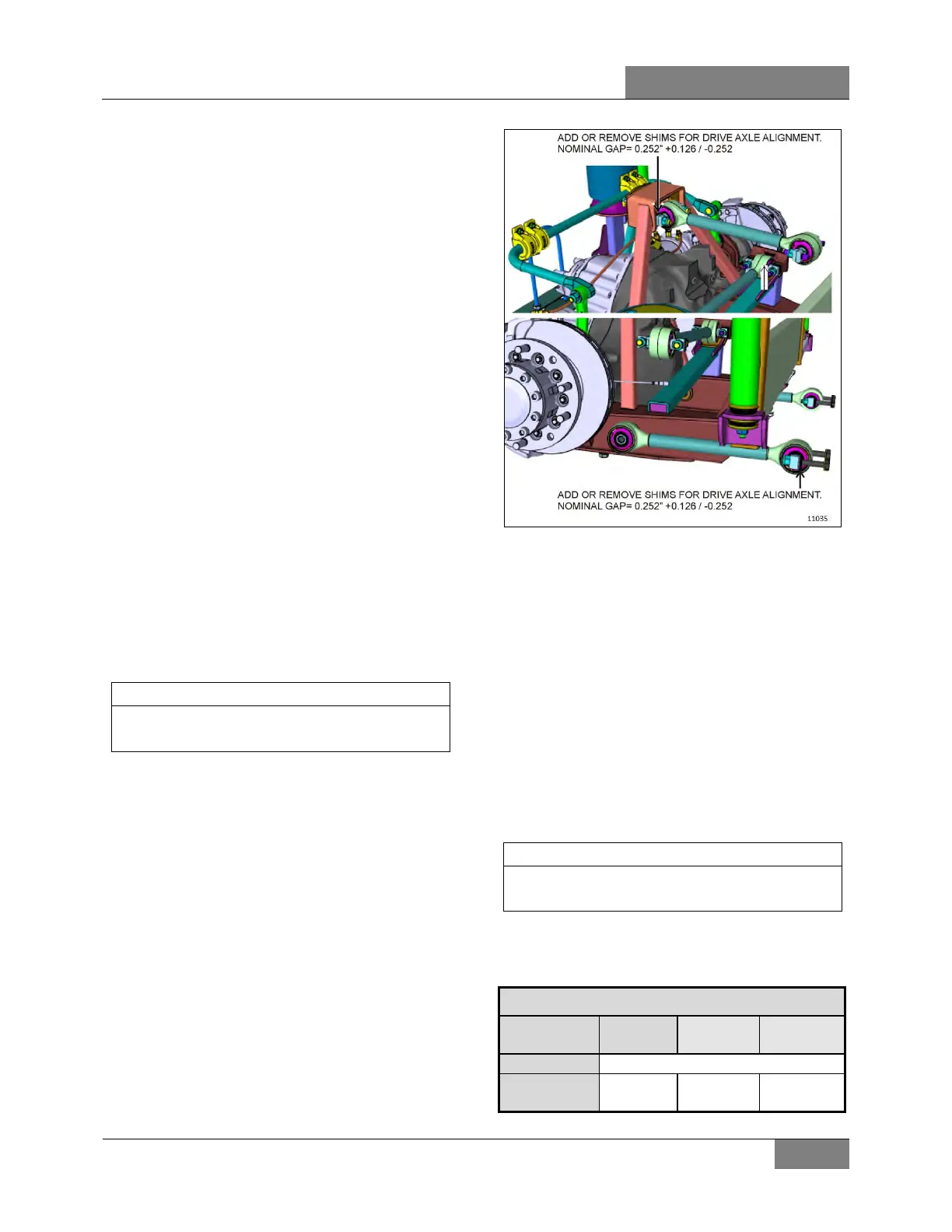

2.5 ZF A132 DRIVE AXLE ALIGNMENT

The drive axle alignment consists in aligning the

axle according to the frame. The axle must be

perpendicular to the frame. The alignment is

achieved with the use of shims inserted between

the lower longitudinal radius rod supports and

the frame.

Drive axle alignment is factory set and is not

subject to any change, except if the vehicle has

been damaged by an accident or if there are

requirements for replacement.

If the axle has been removed for repairs or

servicing and if all the parts are reinstalled

exactly in the same place, the axle alignment is

not necessary. However, if the suspension

supports have been replaced or altered, proceed

with the following instructions to verify or adjust

the drive axle alignment.

When drive axle alignment is modified, tag

axle alignment must be re-verified.

2.5.1 Procedure

1. Park vehicle on a level surface, then chock

front vehicle wheels.

2. Using two jacking points (which are at least

30 inches [76 cm] apart) on drive axle, raise

the vehicle sufficiently so that wheels can

turn freely at about ½ inch from ground.

Secure in this position with safety stands,

and release parking brake.

3. Install wheel mount sensors on front end

and drive axle wheels (Figure 8).

Select axle specifications in the appropriate

chart.

4. With the system installed as in Figure 8,

adjust drive axle according to specifications'

chart below.

0°

Loading...

Loading...