DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

13.8 TIE ROD INSPECTION PROCEDURE

The steering tie rod assembly requires several visual and functional inspections. If any of the described

conditions are found, a complete replacement of the tie rod assembly or individual ball joints may be

required.

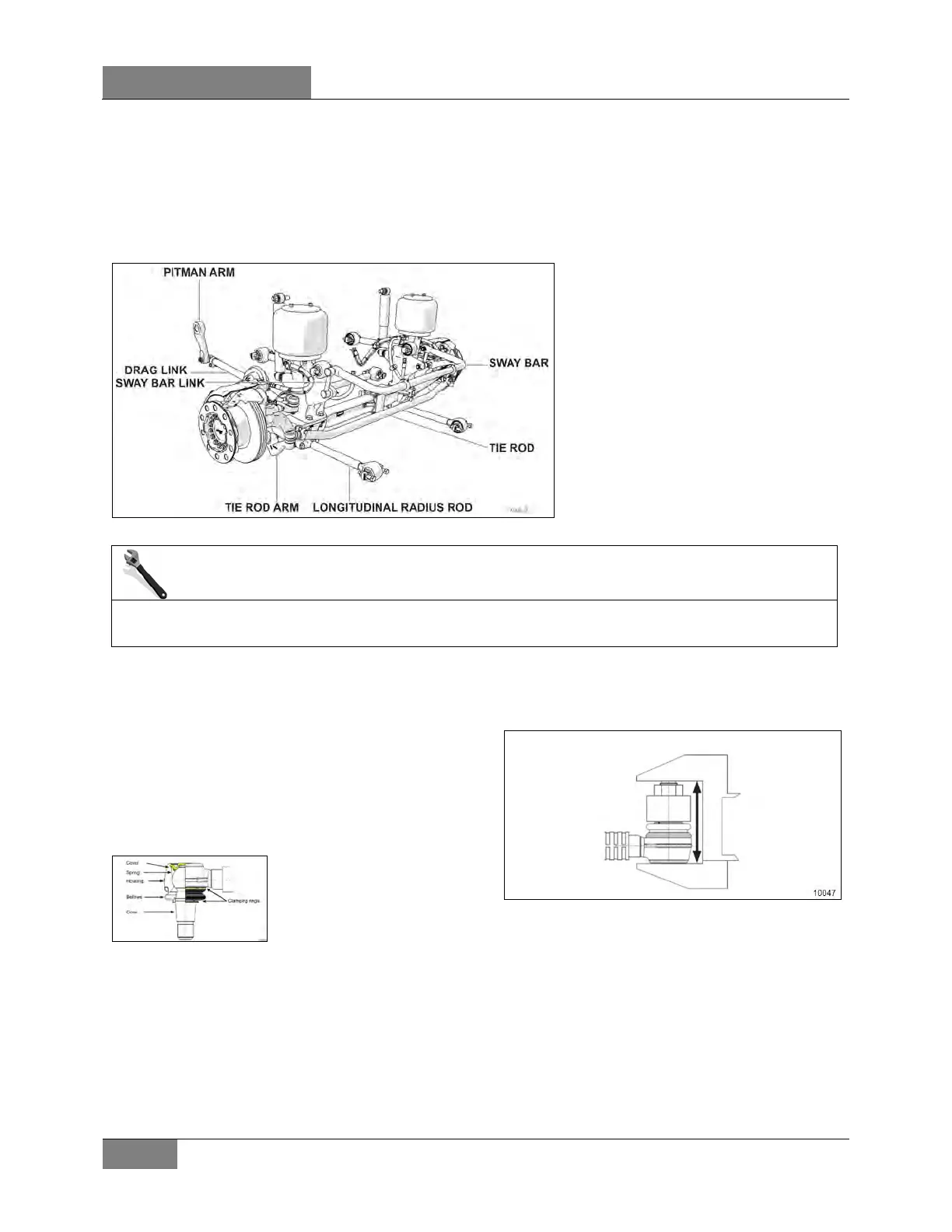

FIGURE 31: FRONT I-BEAM AXLE

13.8.1 Tube inspection

Check the tube for damage. If there are signs of

deformation, replace the tie rod assembly.

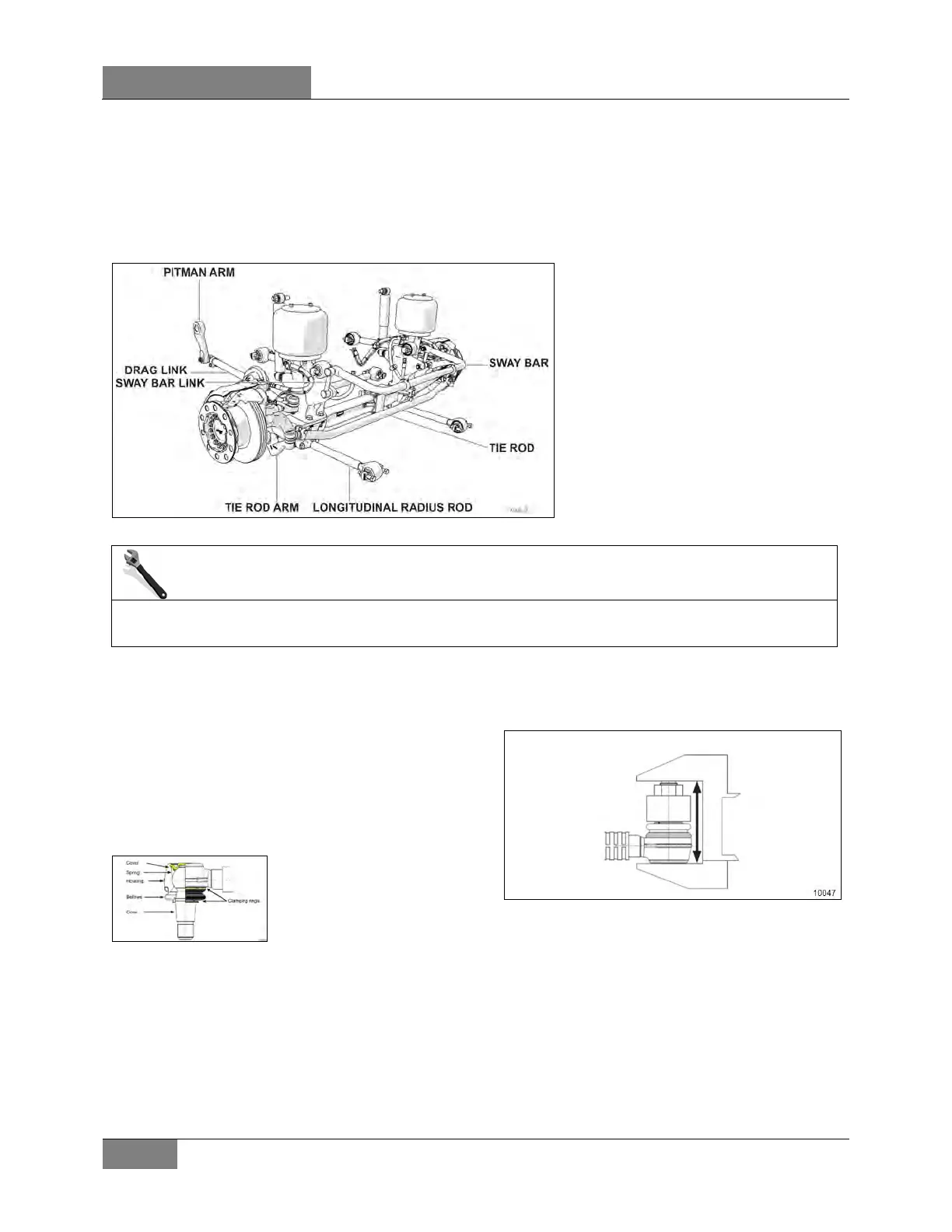

13.8.2 Ball joint play inspection – component

group 33 X-Cap

FIGURE 32 TIE ROD BALL JOINT

To inspect joint wear and play, turn the wheels

alternately left and right until the wheels move.

Perform this with the axle loaded normally.

During this process, the ball stud must not

deflect axially any more than 0.020" (0.5 mm)

into the housing. Replace the joint if the

movement of the ball stud exceeds 0.020" (0.5

mm) axially in the housing.

Measure the distance with a caliper (Figure 33).

FIGURE 33: MEASURING AXIAL PLAY, TIE ROD JOINTS

13.8.3 Fine adjustment sleeve play inspection

Turn the wheels alternately left and right while

keeping a finger on the threads to feel any

movement in the threads. (Figure 34). If there is

too much play in the sleeve, replace the tie rod.

MAINTENANCE

Inspect the tie rod at the interval specified by the Lubrication And Servicing Schedule in Section 24A:

LUBRICATION & SERVICING

Loading...

Loading...