SECTION 22: HEATING AND AIR CONDITIONING

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

• Check the oil level first, according to

“Maintenance - Oil Color & Level Check”.

• Connect the refrigerant recovery station to

the service connections of the shut-off

valves.

• Isolate the compressor from the system. To

do so, front seat the compressor shutoff

valves.

• Extract the refrigerant using the recovery

station until ambient pressure is reached.

Take note of the quantity removed.

• Remove the magnetic drain plug.

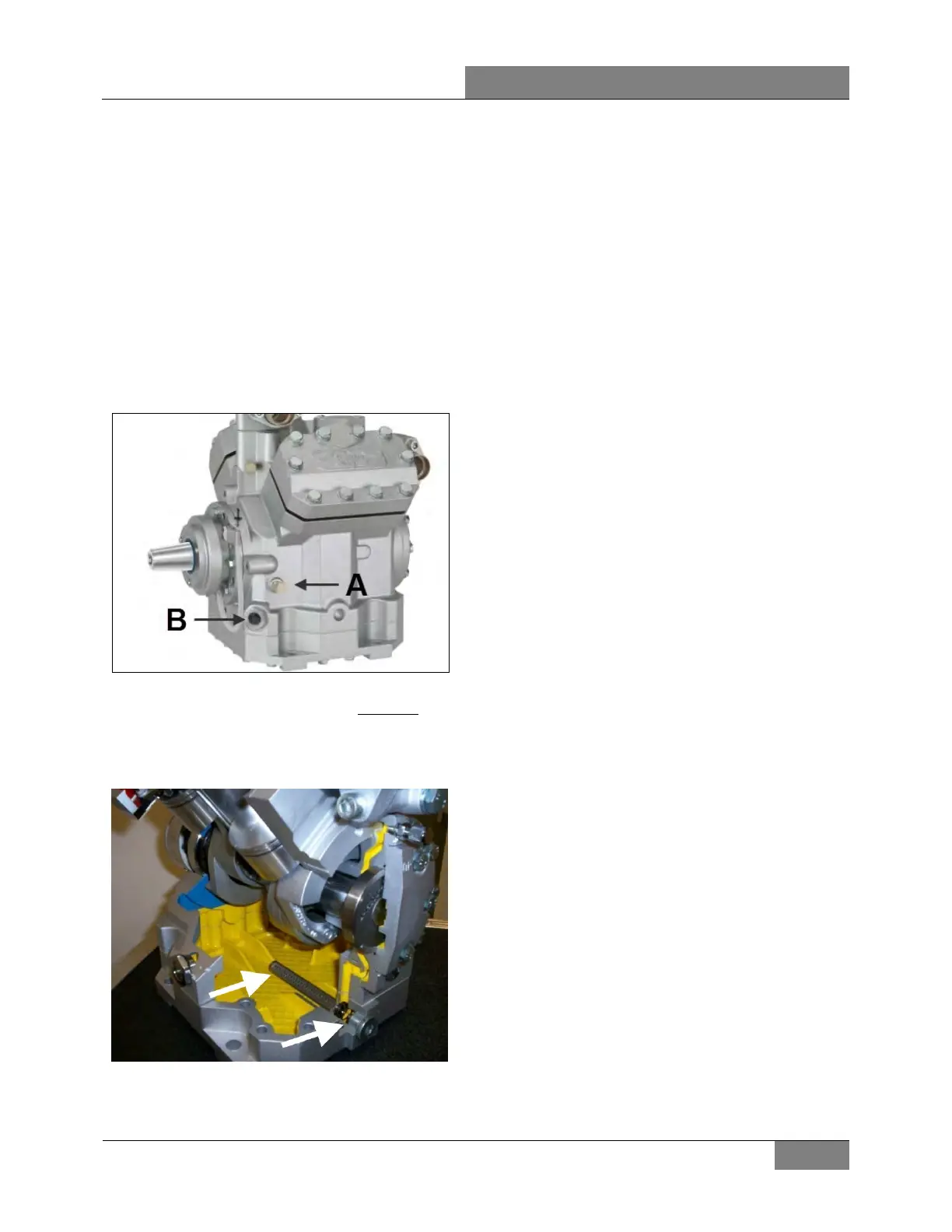

FIGURE 20: OIL FILL PLUG (A) AND SIGHT GLASS (B)

• Drain the oil into a container. Measure the

quantity of oil removed.

• Extract and clean the oil filter/strainer.

Reinstall once done.

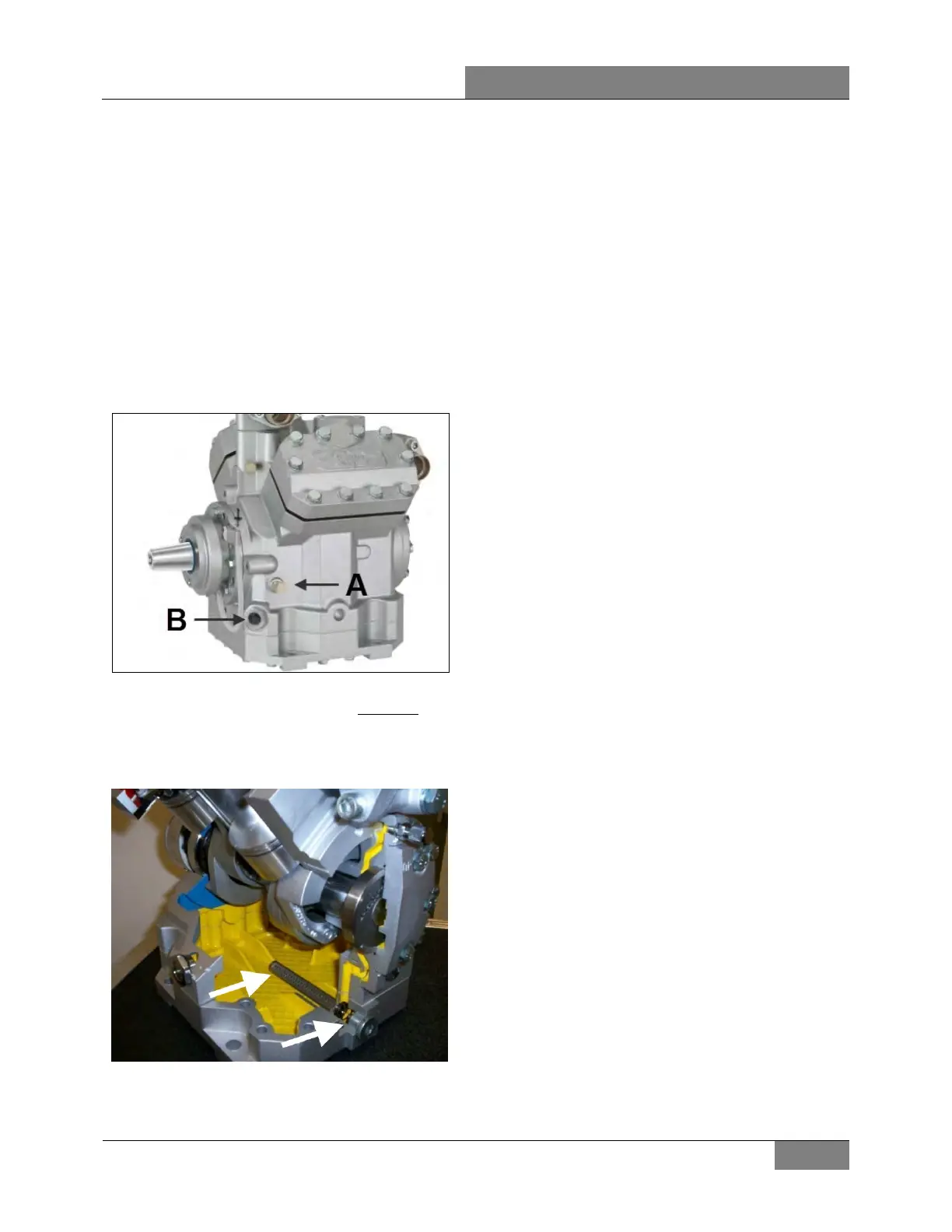

FIGURE 21: CUTAWAY VIEW SHOWING OIL

FILTER/STRAINER AND MAGNETIC DRAIN PLUG

• Clean the magnetic drain plug and reinstall.

• Through the oil filling port, add the same

amount of fresh oil. More oil should be added

if the oil level was too low when checked at

the beginning.

• Evacuate the compressor to 500 microns.

• Charge the system with new refrigerant.

Charge with the same quantity as recovered

previously.

4.1.6 Troubleshooting Guide

A preliminary check may be made by simply

feeling the cylinder heads with the unit in

operation at ambient temperatures of 35

o

F (2

o

C)

and over. The cylinder heads are internally

divided into suction and discharge areas. The

upper central section of the cylinder is the

suction side and it should be relatively cool to

the touch, as opposed to the hot discharge area

which is the lowest perimeter area of the

cylinder head. If a valve plate or head gasket is

blown, or a compressor unloader is stuck open,

partially compressed refrigerant vapor will be

circulated between the suction and discharge

sides of the head. The affected cylinder head

will then have a relatively even temperature

across its surface and be neither as hot as the

normal discharge temperature nor as cool as the

normal suction temperature.

Blown Head Gaskets

Symptom:

• Loss of unit capacity at low temperature.

• Even cylinder head temperature.

Cause:

• Improperly torqued cylinder head bolts.

• Improperly positioned gasket at assembly.

• Warped cylinder head.

• Severe liquid refrigerant flood back.

Blown Valve Plate Gaskets

Symptom:

• Loss of unit capacity at medium and low

temperatures.

• Very hot cylinder head surface.

• Higher than normal suction pressure.

Cause:

• Improperly torqued cylinder head bolts.

Loading...

Loading...