DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

CAUTION

Fuel in the old filter must absolutely not be

poured into the new filter. This kind of

contaminated fuel can damage the unit

injectors.

6. Prime the fuel system by pumping the hand

priming pump on the fuel filter housing until

resistance is felt indicating that the system is

full of fuel.

7. Start the engine and carry out a

fuel-tightness check. Let the engine run for

about 5 minutes to remove air pockets from

the fuel system.

2.4 FUEL PUMP REMOVAL AND

INSTALLATION

The pump is located underneath the air

compressor and is accessible through the engine

compartment R.H. access door.

To remove the pump, proceed as follows:

• Clean around the fuel pump and fuel lines.

Position a container to catch any fuel that

might drain from the pump or lines.

• Remove the fuel pump.

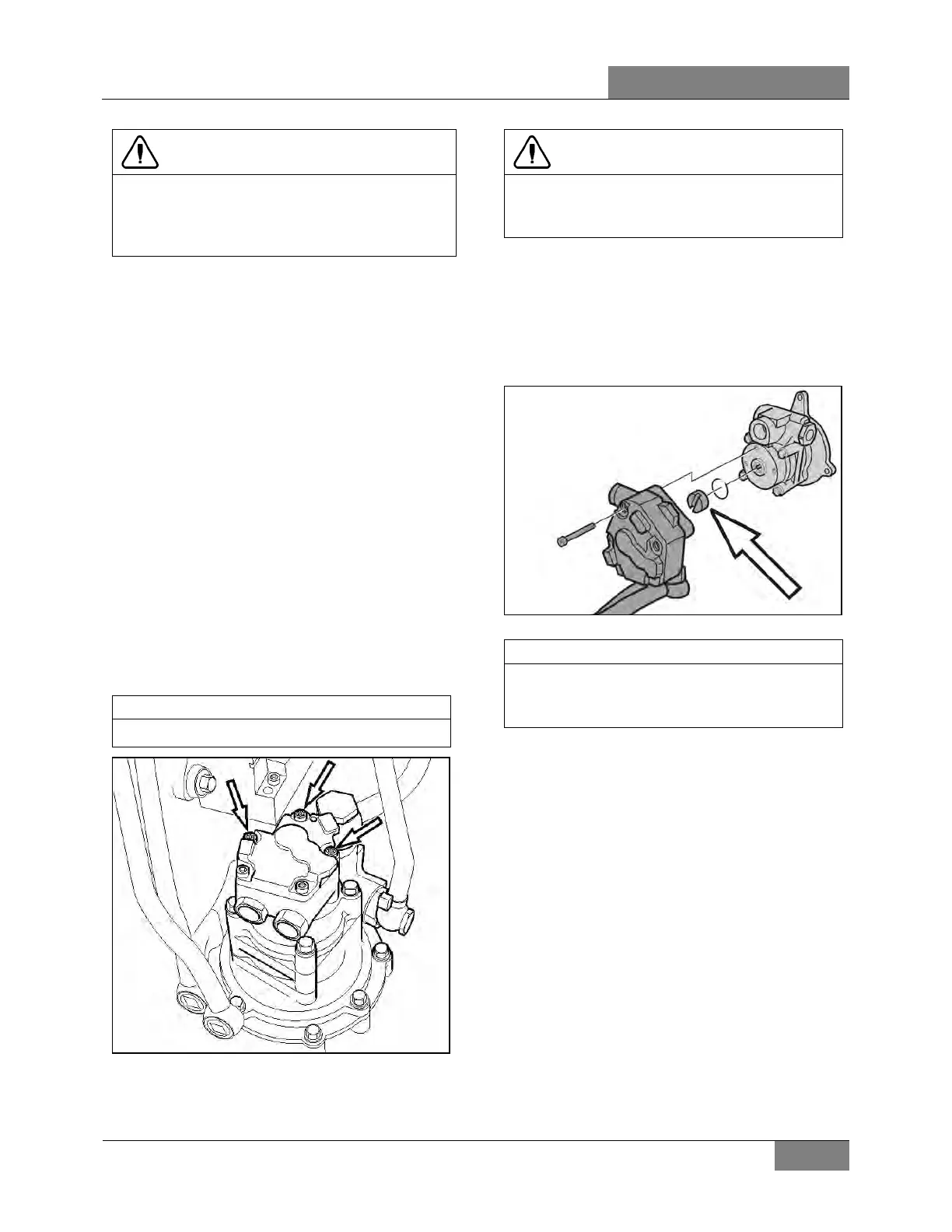

Only unfasten the bolts marked with arrows.

FIGURE 9: FUEL PUMP REMOVAL

CAUTION

Ensure to clean around the head of the bolts.

Debris will prevent the tool from fitting properly

and cause damage to the fasteners.

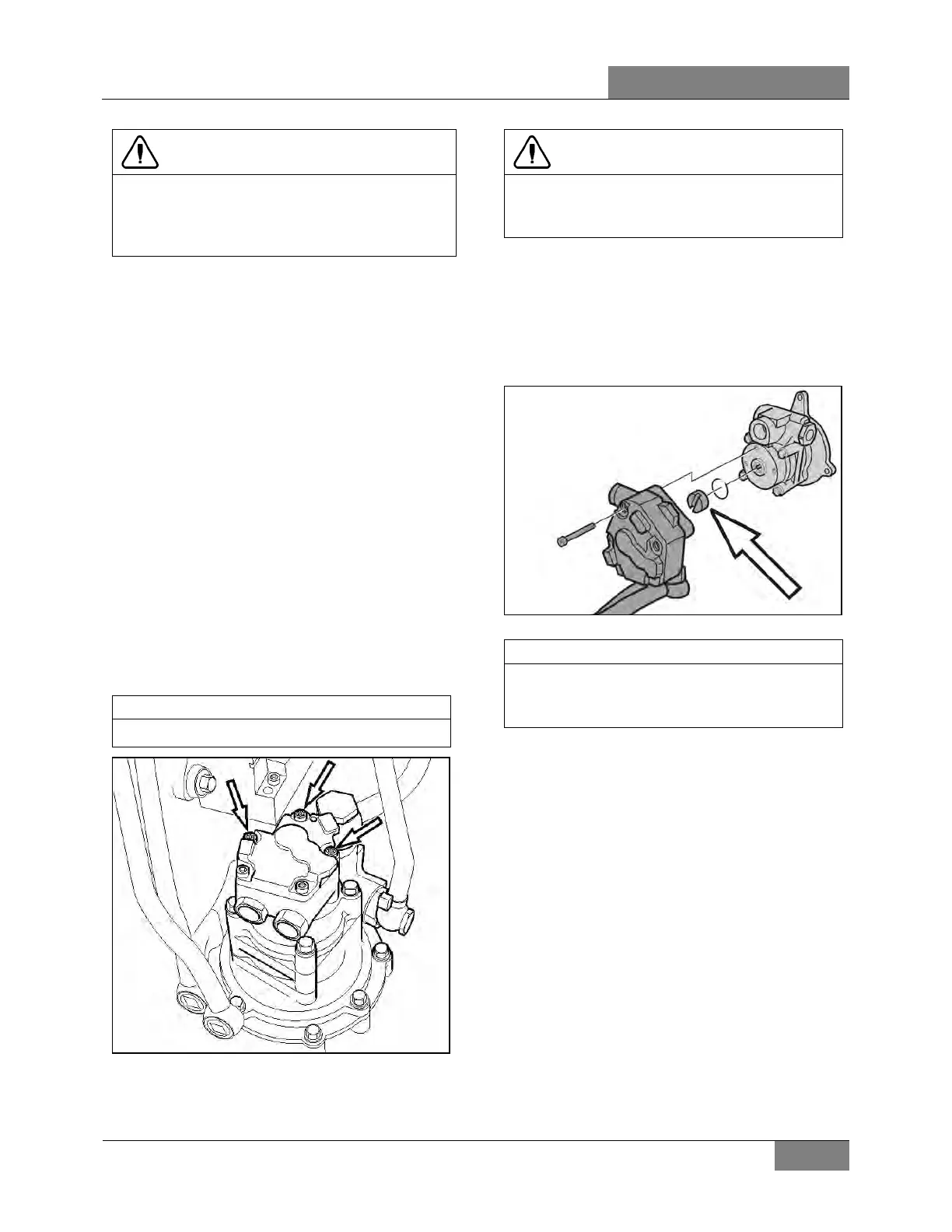

• Check that the adapter and fuel pump drive

axle are not damaged.

• Install the fuel pump. Torque-tighten bolts to

specification.

TORQUE: 6-7 lb-ft (8-9 Nm)

FIGURE 10: FUEL PUMP DRIVE AXLE

Use a new sealing ring. Check that the fuel

pump drive axle sits correctl

steering pump.

• Using the hand primer on the fuel filter

housing, prime the fuel system.

• Start the engine and let run for 5 minutes.

Make sure that there are no leaks.

Loading...

Loading...