DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

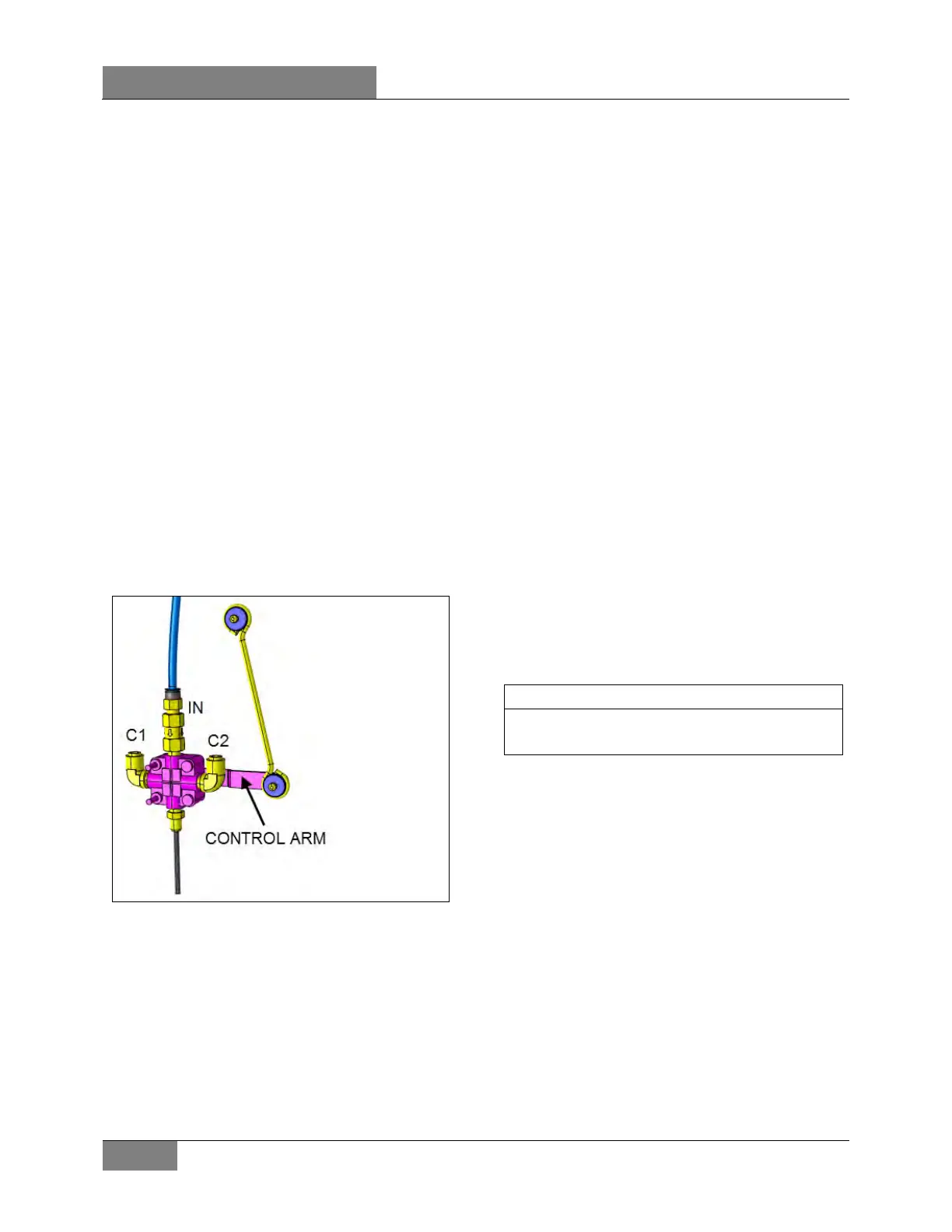

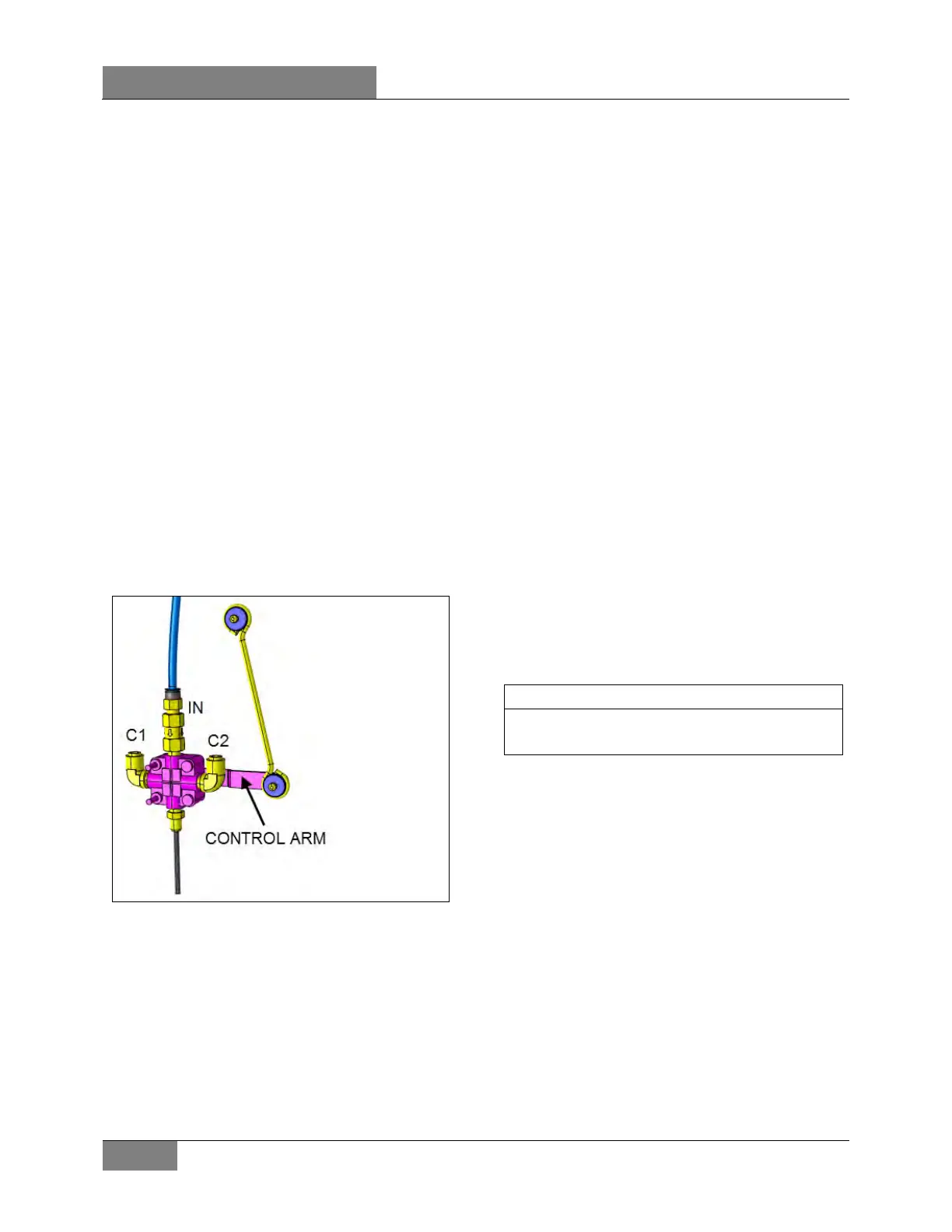

6.2 HEIGHT CONTROL VALVES

The height control valves automatically add air

to, or release air from air springs to maintain

constant suspension height regardless of load,

or load distribution. Each valve adjusts

independently according to the following

conditions:

Loading position

As the load increases and lowers the vehicle

body, the control arm commands the height

control valve to add air to air springs.

Neutral position

When vehicle body reaches the normal ride

height, the height control valve control arm

reaches the "neutral" position and keeps both

the supply and exhaust ports closed to ensure

normal ride height is maintained. This condition

remains static until the vehicle load is altered.

Unloading position

As the load decreases and raises the vehicle

body, the control arm commands the height

control valve to release air from air springs.

FIGURE 15: HEIGHT CONTROL VALVE 16093

6.3 MAINTENANCE

The height control valve requires no periodic

maintenance. Height control valve linkage

operates on rubber bushings and no lubrication

should be attempted at this point. Inspect the

valve for loose joints, air leaks and worn

bushings.

6.3.1 Removal and installation

Before disconnecting any height control valve air

lines, securely support the vehicle by its jacking

points on the body, and place safety support

underneath body. Refer to "VEHICLE JACKING

POINTS" in Section 18, "Body".

1. Exhaust air from air system by opening the

drain cock on accessory air reservoir.

Remove height control valves.

2. Disconnect overtravel lever from link and

pull down lever to exhaust remaining air from

air springs.

3. Disconnect air supply and delivery lines from

the height control valve. Cover ends of the

lines with tape to prevent entry of foreign

matter.

4. Remove the nuts retaining the height control

valve to the mounting bracket, then remove

valve assembly.

Note: The height control valve bolts

equipped with a nylon insert should be

replaced after the third (3rd) tightening.

Reverse removal procedure to replace height

control valve. After installation, check for leakage

using a soap and water solution.

6.3.2 Air leakage test

The following procedure applies when valve

assembly has been removed from vehicle.

1. Clean the exterior of valve assembly.

2. Connect air pressure line to air inlet port,

then allow air pressure build-up (70- 100 psi

(480 - 690 kPa)).

3. Dip the valve assembly in a container full of

water, and watch for air bubbles when the

control arm is in the center position. No air

should escape from any point of the valve

assembly.

4. If bubbles appear from the air spring port,

this is an indication that the air inlet valve

assembly is defective and must be replaced.

5. Remove air pressure line from air inlet fitting

and connect it to the air spring port. If

bubbles appear at the air inlet check valve

port, this is an indication that the check valve

unit is defective and must be replaced.

Loading...

Loading...