DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

99

12.3.3 Repair Of A Welded Joint

In wintertime, condensation and cold

temperature may greatly influ

ence bonding

parameters. Working area must be at a

temperature sufficient to prevent reaching

condensation point. Mechanically preheat

working area (heat lamp or heat gun) or wait

until vehicle reaches room temperature.

1. Using a knife, remove portion of joint to be

repaired.

Loss of adhesion may be local. If this is the

case, repair may also be local.

2. Chamfer and re-weld the joint as shown in

section 11.3.2, Section: Welding of Joint

between White Safety Strip and “Tarabus”

Floor Covering.

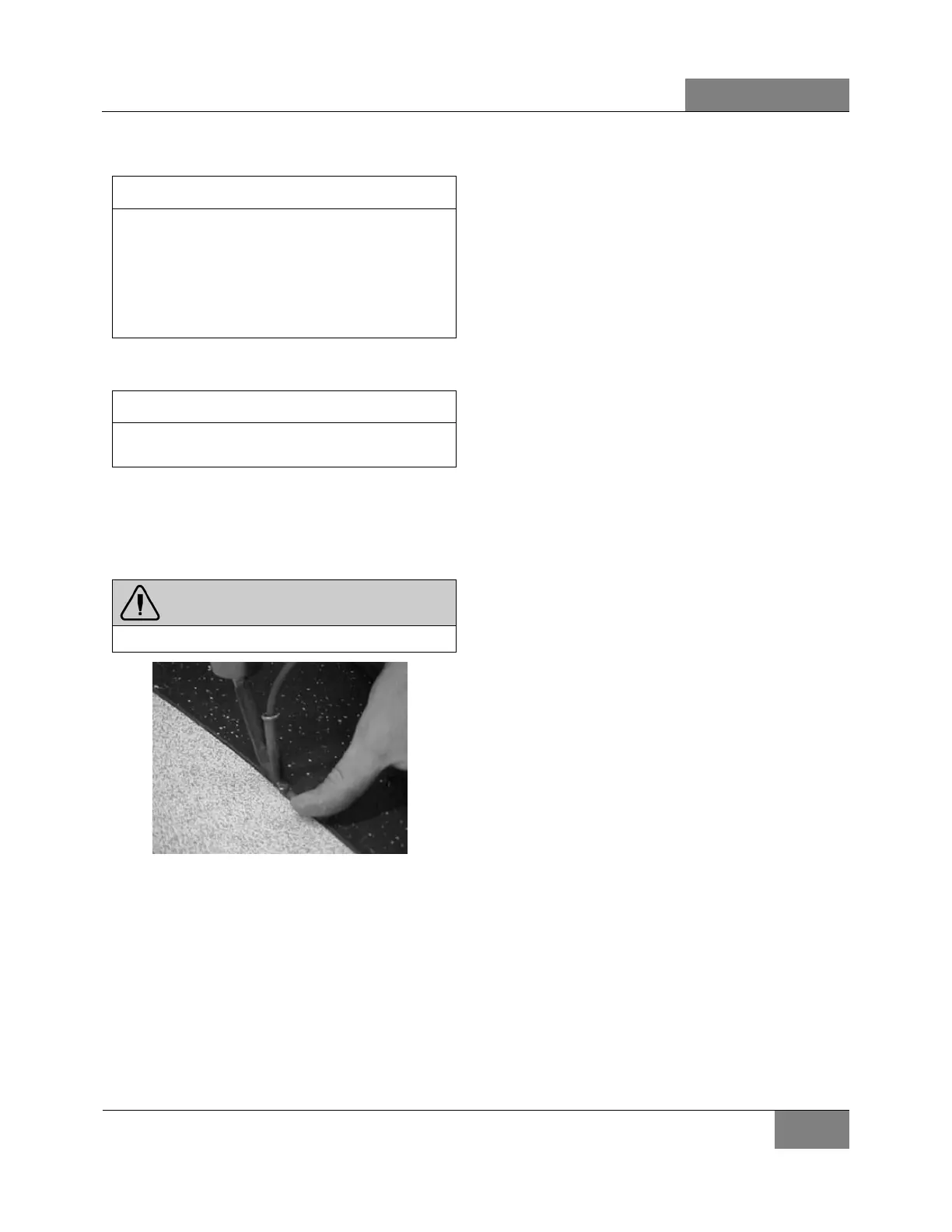

WARNING

Nozzle is hot.

3. Always add an extra inch of filler bead at the

beginning and at the end of repair.

4. Perform steps 9, 10 and 11 in section

11.3.2.

Loading...

Loading...