DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual Section 01 revised Jan 2021

2.6 POWER PLANT ASSEMBLY REMOVAL

To access the engine or engine-related

components, the vehicle power plant assembly

must be removed as a whole unit by means of a

slide-out cradle. The power plant assembly

includes the engine, transmission (including

retarder), alternator and transmission oil cooler.

Remove the power plant assembly as follows:

CAUTION

Tag hoses and cables for identification before

disconnecting in order to facilitate reinstallation.

Plug all openings to prevent dirt from entering

the system.

No parts within the EECU are serviceable. If

found defective, replace the EECU as a unit.

• First

1. Close the heater line shut-off valves.

2. Disconnect batteries from the starting

system by removing battery cables. With

the electrical circuit disrupted, accidental

contact with the starter button will not

produce an engine start.

WARNING

Due to the heavy load of the rear bumper

assembly, it must be adequately supported

before attempting to remove it.

3. Remove the rear bumper assembly

complete with hitch if applicable from the

vehicle. Refer to Section 18, BODY, under

"REAR BUMPER REMOVAL".

4. Using the quick-connect drain hose, drain

the engine cooling system. Refer to

Section 05, COOLING under "DRAINING

COOLING SYSTEM".

• Begin With Vehicle Raised

1. Using a vehicle lift or jack, raise vehicle to

access transmission fasteners and wire

harness.

2. From under the vehicle, disconnect the

propeller shaft as detailed in Section 09,

under heading "Propeller Shaft Removal”.

3. Partially remove L.H. side transmission

protective panel to access connectors.

4. Disconnect transmission harness from

transmission housing.

5. Disconnect steel-braided airline from

pressure regulator output. The pressure

regulator is mounted in the upper section

of the engine compartment backwall and

is accessible through the engine

compartment R.H. side door.

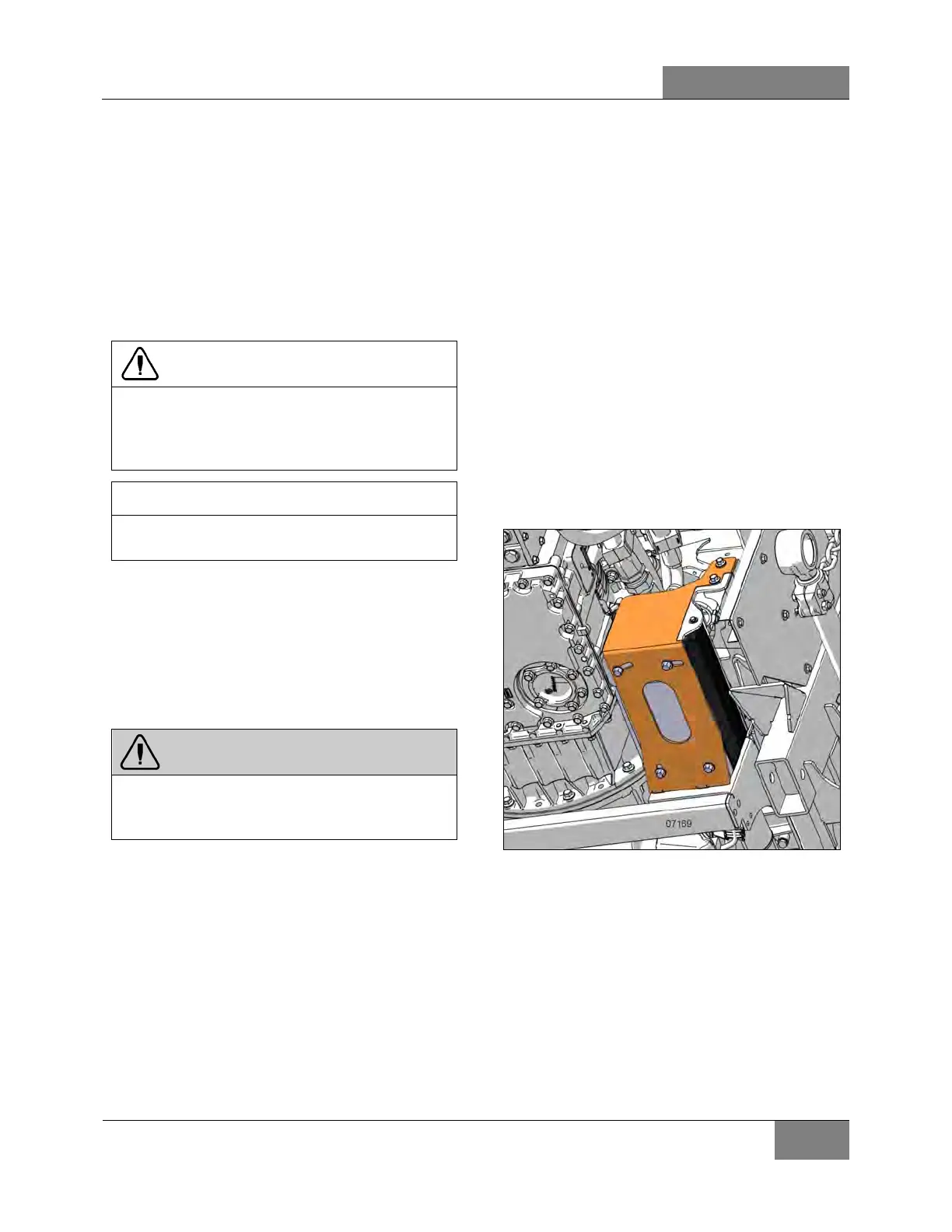

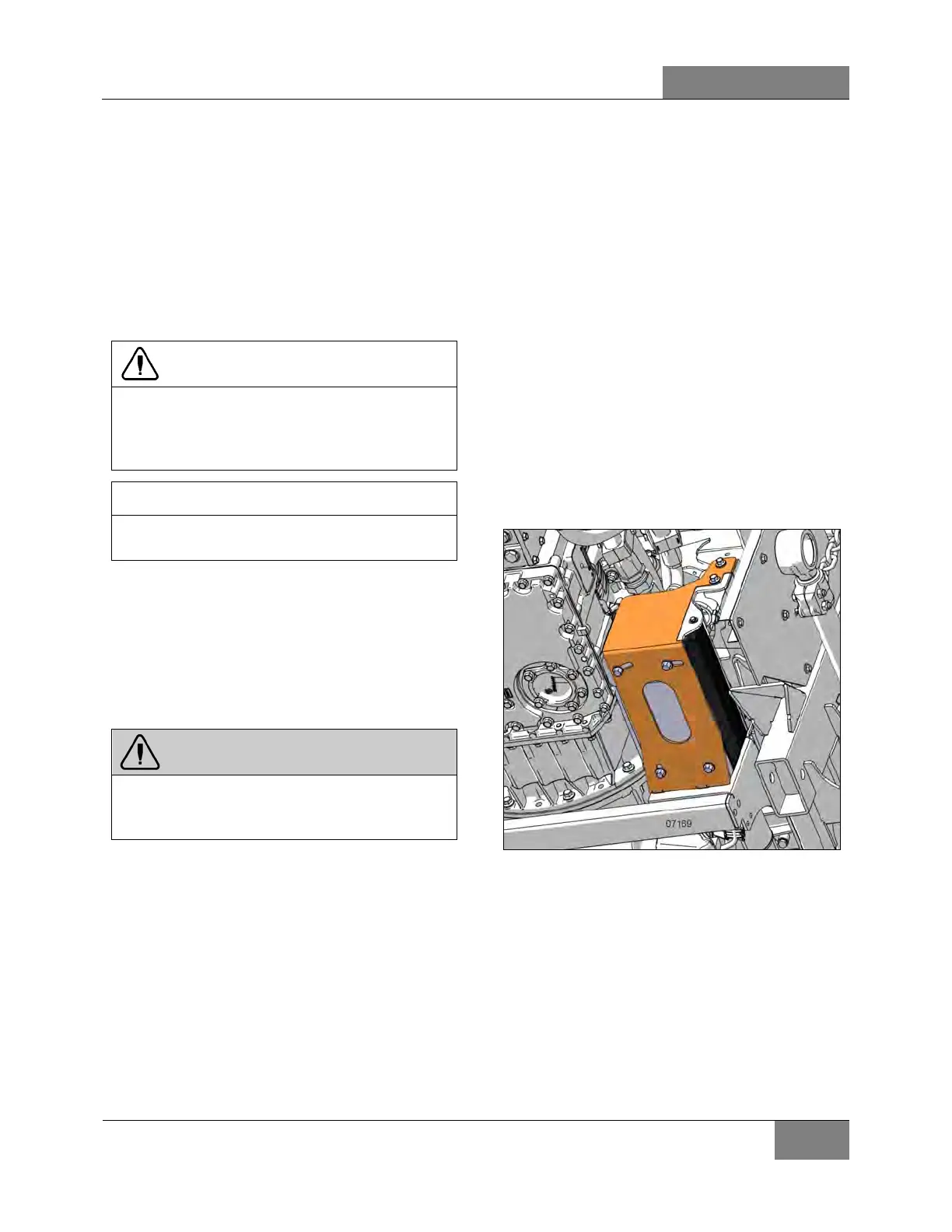

6. Locate the transmission oil cooler beside

the transmission on the driver side.

Untighten bolts A, B, C and D and pivot

the transmission oil cooler towards the

transmission.

FIGURE 12: COOLER POSITION DURING ENGINE

CRADLE INSERTION OR REMOVAL

7. Remove the retaining bolts, washers and

nuts securing the power plant cradle to

the vehicle rear subframe.

8. Disconnect the engine coolant hose near

the starter.

9. Disconnect air compressor suction and

discharge hoses.

Loading...

Loading...