SECTION 05: COOLING SYSTEM

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

9.2 REVERSE FLUSHING

After the engine and radiator have been

thoroughly de-scaled, they should be reverse-

flushed. The water pump should be removed

and the radiator and engine reverse-flushed

separately to prevent dirt and scale deposits

from clogging the radiator tubes or being forced

through the pump. Reverse flushing is

accomplished by hot water, under pressure,

being forced through the cooling system in a

direction opposite to the normal flow of coolant,

loosening and forcing deposits out.

The radiator is reverse flushed as follows:

1. Remove the radiator inlet and outlet hoses

and replace existing radiator cap with a new

one.

2. Attach a hose to the top of the radiator to lead

water away from the engine.

3. Attach a hose at the bottom of the radiator

and insert a flushing gun in the hose.

4. Connect the water hose of the gun to the

water outlet and the air hose to the

compressed air outlet.

5. Turn on the water and when the radiator is

full, turn on the air in short blasts, allowing the

radiator to fill between blasts.

Apply air gradually. Do not exert more than

138 kPa (20 psi) air pressure. Too great a

pressure may rupture a radiator tube.

6. Continue flushing until only clean water is

expelled from the radiator.

The cylinder block and cylinder head water

passages are reverse flushed as follows:

1. Remove the thermostats and the water

pump.

2. Attach a hose to the water inlet of oil cooler

housing to drain water away from engine.

3. Attach a hose to the water outlet at the top of

the cylinder head (thermostat housing) and

insert the flushing gun in the hose.

4. Turn on the water until the jackets are filled,

and then turn on the air in short blasts. Allow

jackets to fill with water between air blasts.

5. Continue flushing until the water from the

engine runs clean.

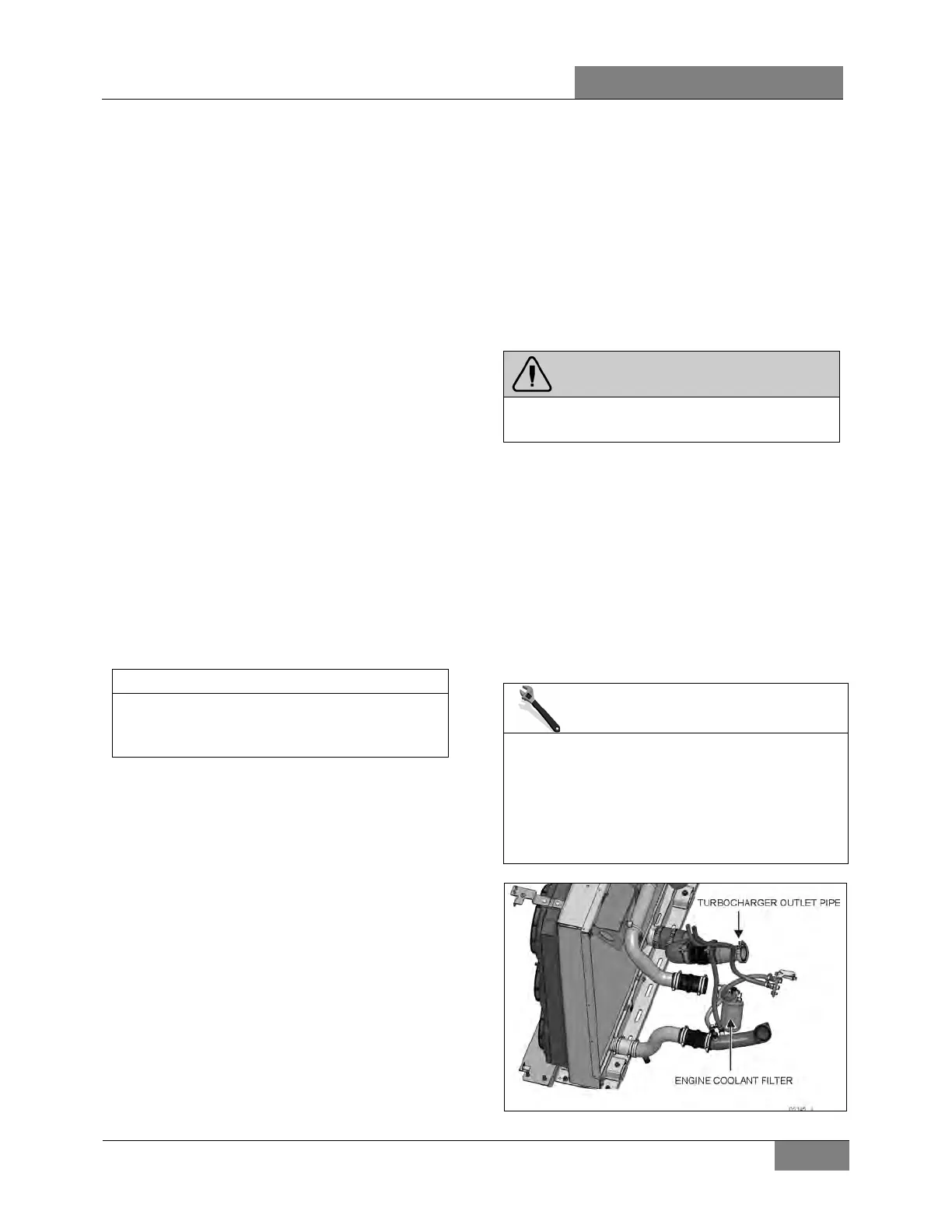

10. SPIN-ON COOLANT FILTER

The engine cooling system filter is used to filter

out impurities such as scale or sand from the

coolant. The filter is mounted on the frame below

the turbocharger inlet tube (Figure 21).

To replace a filter:

1. Close the filter shutoff cock on the filter

mounting head and unscrew the old filter

from mounting.

WARNING

Failure to relieve cooling system pressure may

result in personal injury.

2. Remove and discard the filter. Recover the

coolant remaining in the filter with a suitable

container.

3. Clean the filter adapter with a clean, lint-free

cloth.

4. Coat surface of gasket with clean antifreeze,

tighten 2/3 to 1 turn after gasket makes

contact with head.

5. Open the filter shutoff cock.

6. Start engine and check for leaks.

MAINTENANCE

Coolant filter

Replace the coolant filter cartridge

at the

intervals specified by the Lubrication And

Servicing Schedule in Section 24:

LUBRICATION & SERVICING.

Do not exceed recommended service intervals.

FIGURE 21: COOLANT FILTER

Loading...

Loading...