SECTION 00 : GENERAL INFORMATION

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

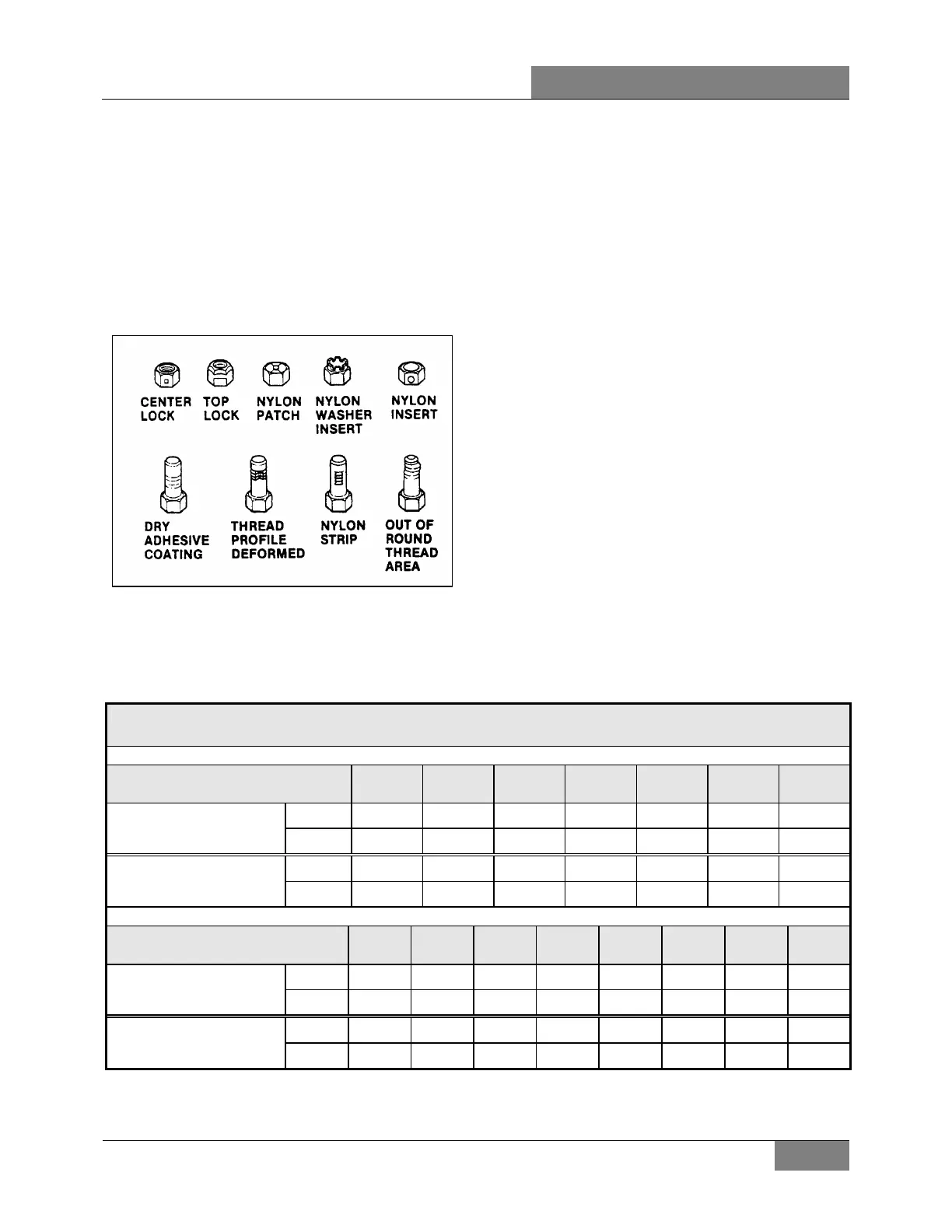

4.3 SELF-LOCKING FASTENERS

A self-locking fastener is designed with an

interference fit between the nut and bolt threads.

This is most often accomplished by distortion of

the top thread of an all-metal nut or bolt or by

using a nylon patch on the threads. A nylon

insert or the use of adhesives may also be used

as a method of interference between nut and

bolt threads (Figure 13).

FIGURE 13: SELF-LOCKING FASTENERS 00004

4.4 RECOMMENDATIONS FOR REUSE

Clean, rust-free self-locking fasteners may be

reused as follows:

a) Clean dirt and other foreign matter from

the fastener;

b) Inspect the fastener to ensure there is no

crack, elongation, or other sign of fatigue

or over tightening. If there is any doubt,

replace with a new self-locking fastener of

equal or greater strength;

c) Assemble parts and hand start fastener;

d) Observe that, before the fastener seats, it

develops torque per the chart in the

following table. If there is any doubt,

replace with a new self-locking fastener of

equal or greater strength;

e) Tighten the fastener to the torque specified

in the applicable section of this manual;

Fasteners which are rusty or damaged should be

replaced with new ones of equal or greater

strength

.

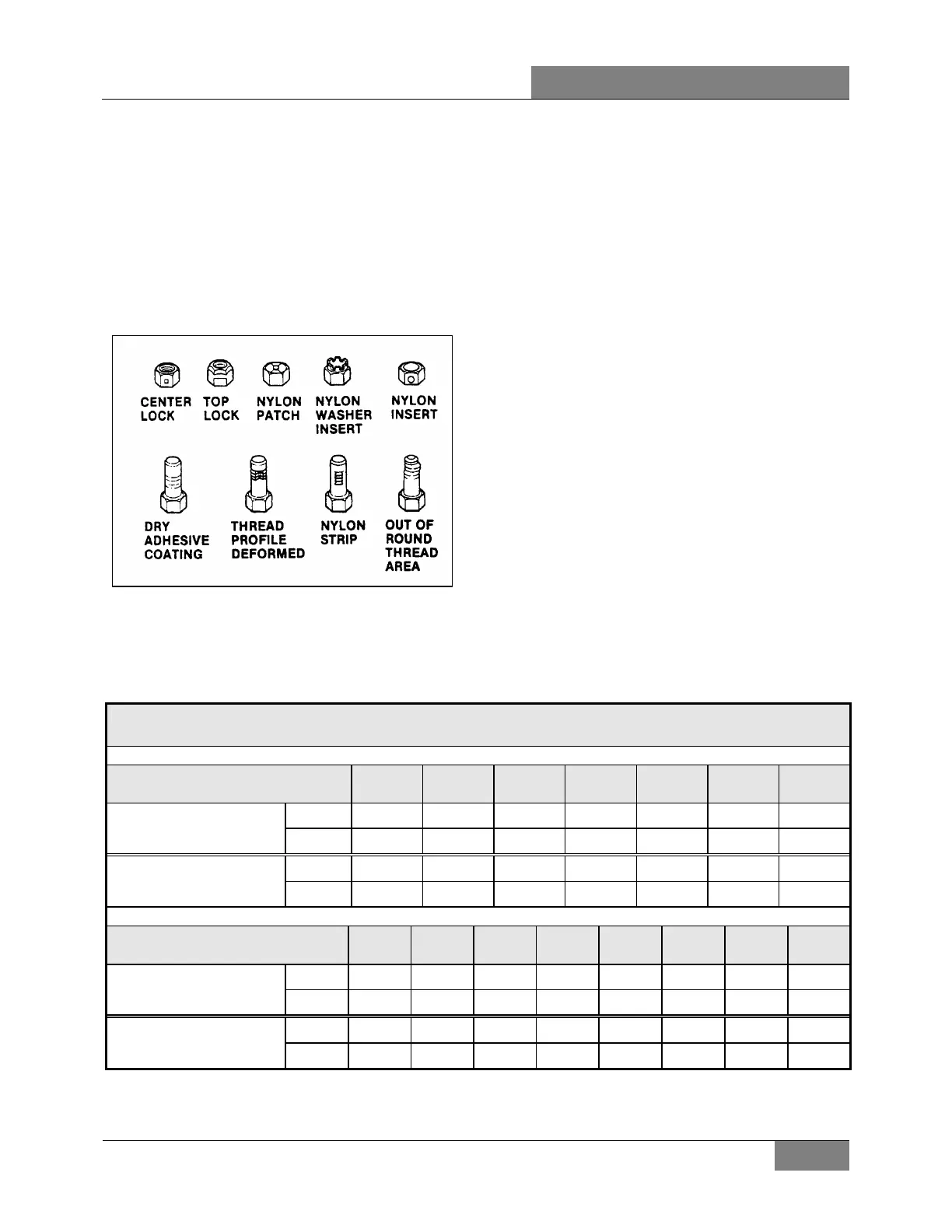

SELF-LOCKING TORQUE CHART BEFORE FASTENER SEATS

METRIC

6 & 6.3 8 10 12 14 16 20

NUTS AND Nm 0.4 0.8 1.4 2.2 3.0 4.2 7.0

ALL-METAL BOLTS lb-in 4.0 7.0 12 18 25 35 57

ADHESIVE OR NYLON Nm 0.4 0.6 1.2 1.6 2.4 3.4 5.6

COATED BOLTS lb-in 4.0 5.0 10 14 20 28 46

US STANDARD

¼ 5/16 3/8 7/16 ½ 9/16 5/8 ¾

NUTS AND Nm 0.4 0.6 1.4 1.8 2.4 3.2 4.2 6.2

ALL-METAL BOLTS lb-in 4.0 5.0 12 15 20 27 35 51

ADHESIVE OR NYLON Nm 0.4 0.6 1.0 1.4 1.8 2.6 3.4 5.2

COATED BOLTS lb-in 4.0 5.0 9.0 12 15 22 28 43

Loading...

Loading...