DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

5. SUSPENSION AIR SYSTEM

The suspension air system has its own air

reservoir (accessory tank) which is located

behind the front axle. Pressurized air from the

main tank (wet tank) flows through a pressure

protection valve (PR-4), to the accessory air tank

and through an air filter which is located in front

service compartment.

The pressure protection valve (PR-4) is mounted

to the supply port of the tank. This valve controls

the pressure at which compressed air is

delivered to the accessory air tank. The valve

remains closed until a preset pressure is

reached (approximately 70 psi (485 kPa)). It then

opens and passes air out the delivery port.

The main use for this valve is to protect the main

air system by ensuring at all times a sufficient air

pressure in the main system (i.e. air delivered to

the accessories will be shut off in case of a

decrease in pressure). Maintenance and repair

information on the pressure protection valve is

supplied in the applicable booklet, annexed to

Section 12, “Brakes and Air System” under

reference number SD-03-2010.

WARNING

Depressurize parts prior to removal.

5.1 INSPECTION

The following inspection should be performed at

established service inspection periods.

Performing these procedures will allow

substandard performance to be discovered

before the condition becomes bad enough to

cause operator complaints or failure during

operation.

1. Visually inspect the suspension air lines for

evidence of chafing on metal parts or other

damage.

2. Visually inspect the air springs for cracks,

abrasion or other damage.

3. Replace any parts found to be damaged.

5.2 AIR LINE TEST

With the main air system at normal operating

pressure, coat all suspension air line

connections and air spring mountings with a

solution of soap and water. Air leakage will

produce soap bubbles. Any leak found must be

corrected as no air leakage is permissible.

6. SUSPENSION HEIGHT ADJUSTMENT

The flow of pressurized air from the accessory

air tank to the air springs is controlled by three

height control valves. These valves are mounted

to the subframe and connected to the axles

through an arm and link connection. This

connection allows the valves to apportion air

pressure in the springs to the vehicle load,

maintaining normal ride height.

To adjust suspension height, refer to

Maintenance Information MI16-14

SUSPENSION HEIGHT ADJUSTMENT USING

HEIGHT CONTROL VALVES included at the

end of this section.

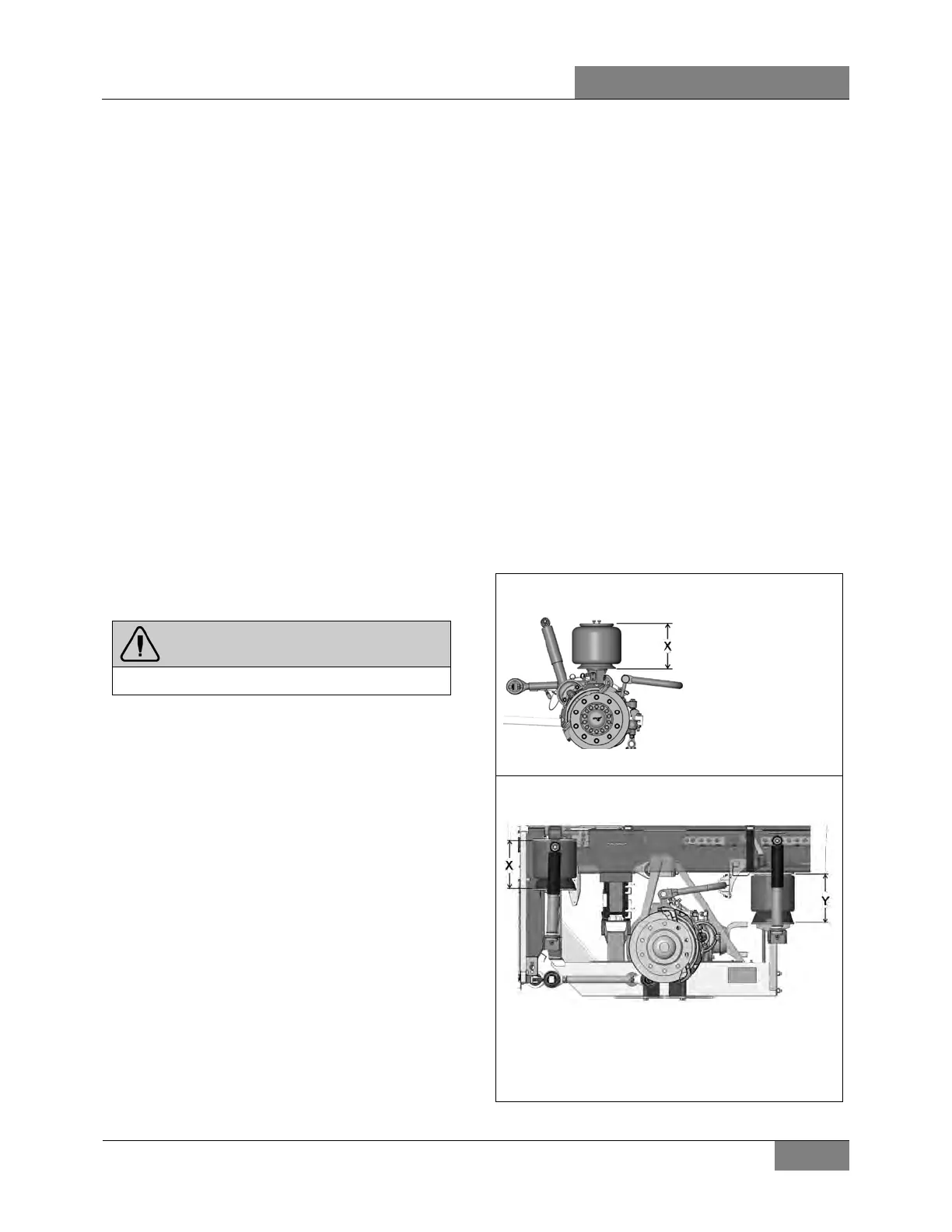

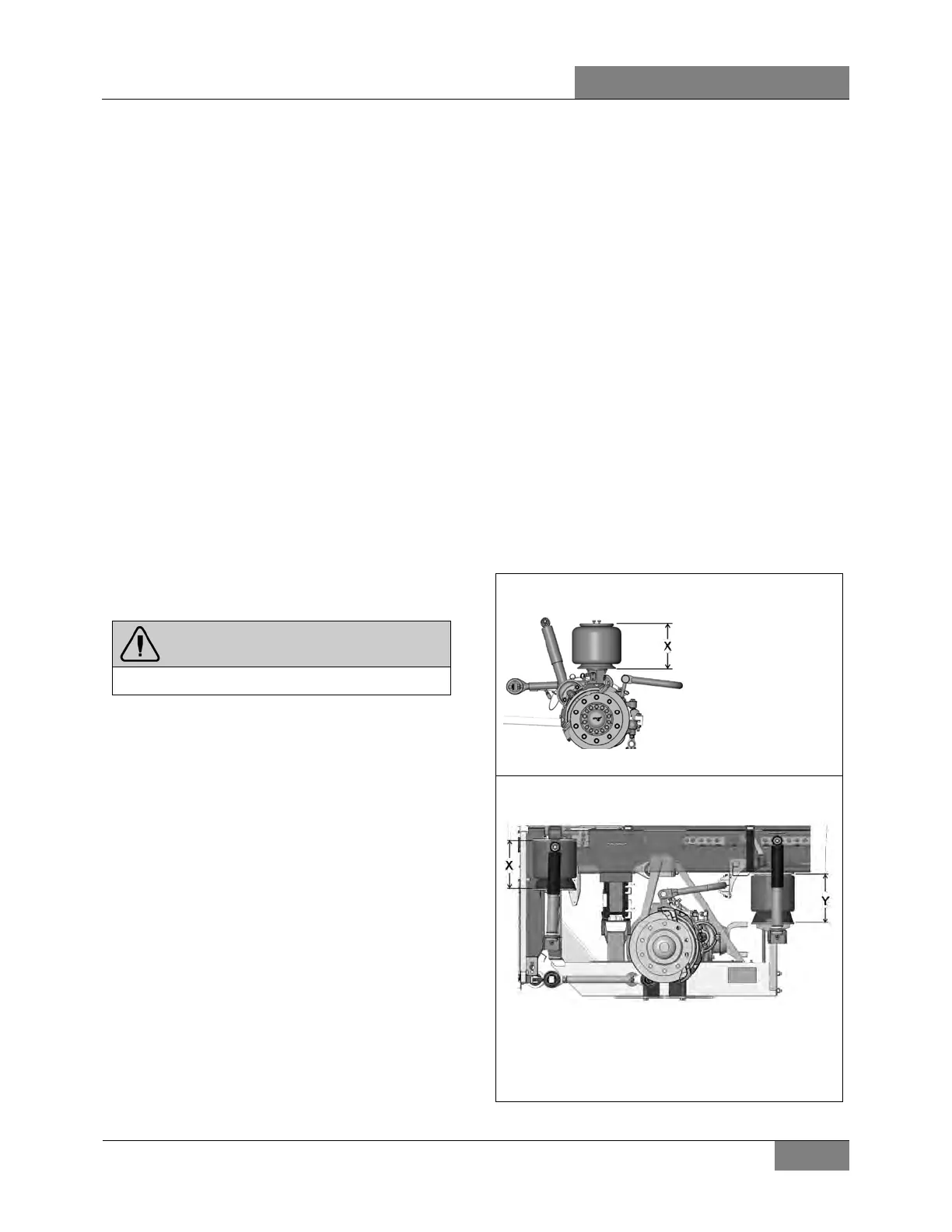

6.1 NORMAL RIDE HEIGHT

The normal ride height is obtained by measuring

and adjusting air spring height of front and rear

suspension.

FRONT SUSPENSION (I-BEAM AXLE)

X = 11 ¾ ± ¼ inch (297 ± 6 mm)

REAR SUSPENSION

FORE AIR SPRINGS

X = 11 ½ ± 1/16 inch (292 ± 1.5 mm)

AFT AIR SPRINGS

Y = 11 ½ ± 1/4 inch (292 ± 6 mm)

Loading...

Loading...