DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

FIGURE 17: JACK STANDS UNDER THE FUEL TANK

CRADLE

2. Carefully inspect fuel cradle mounting bolts, 2

bolts (Figure 18).

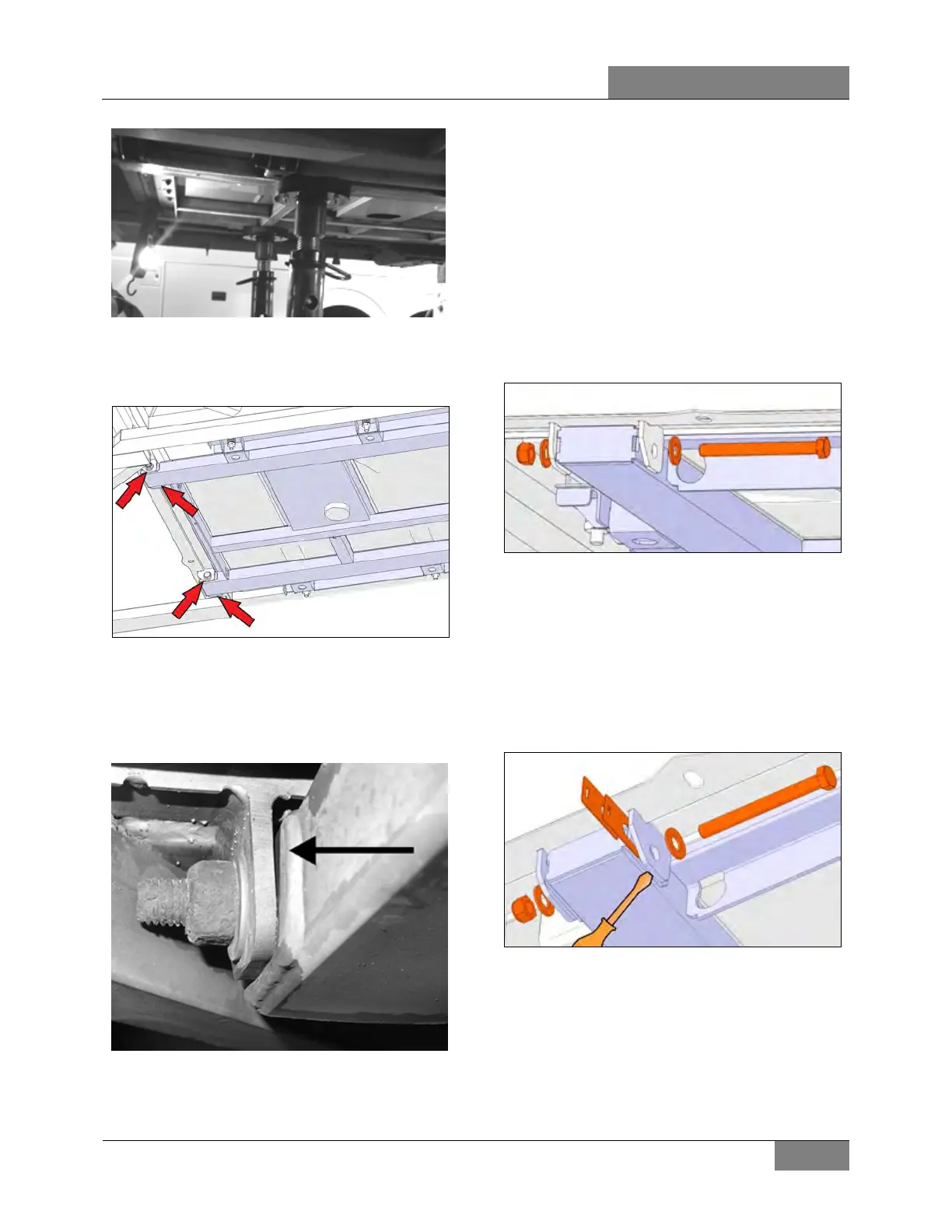

FIGURE 18: SPECIFIC MOUNTING POINTS TO BE

INSPECTED

3. On the transversal screw joints (Figure 19)

any visible gap between cradle support tubing

and vehicle frame mounting lugs is not

acceptable.

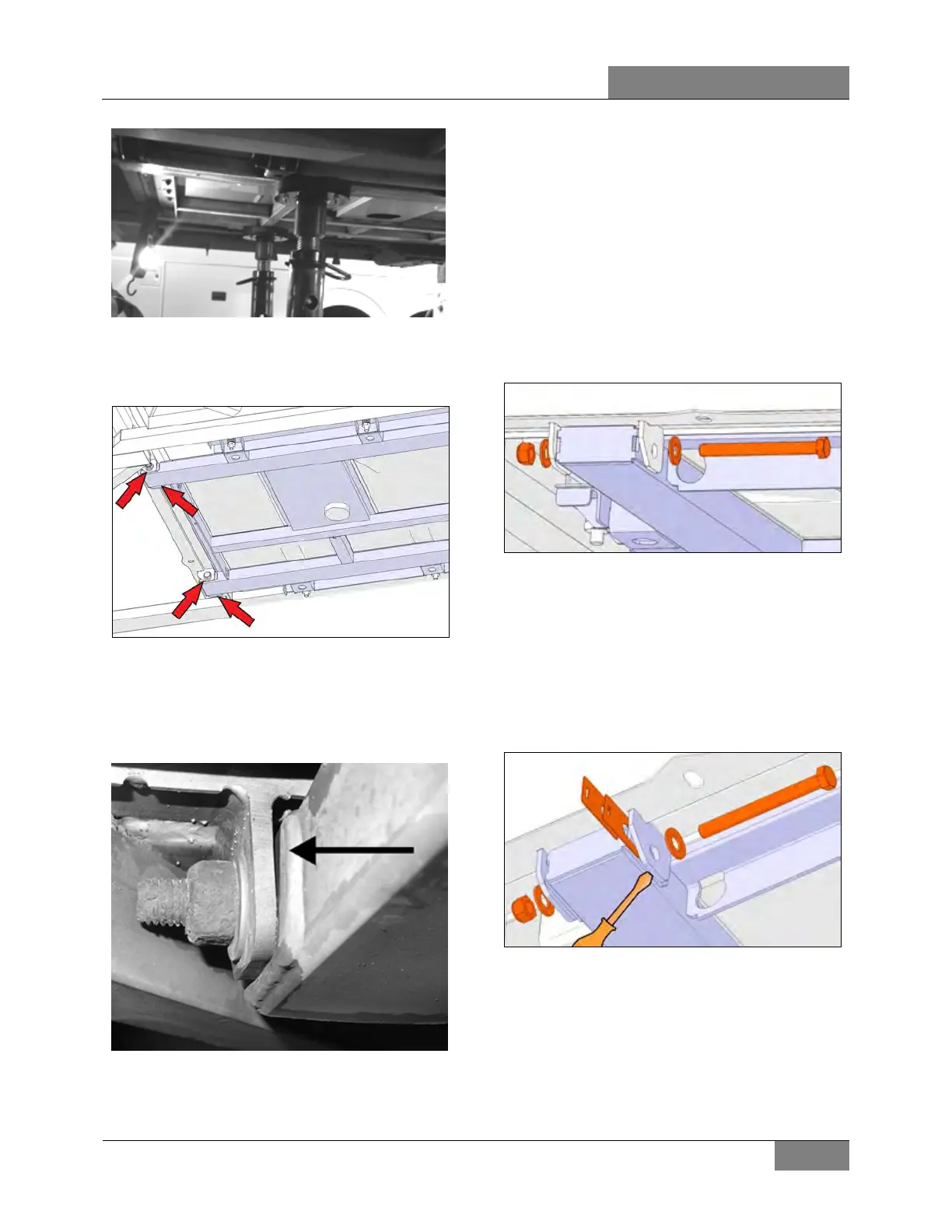

FIGURE 19: VISIBLE GAP ON TRANSVERSAL SCREW

JOINT

4. If there is no gap, the inspection is

completed. Else, perform the following Fuel

Tank cradle Corrective Measures.

4.4.1 Fuel Tank Cradle Corrective Measures

Visible gap should be shimmed using U-shims

#030082 (3.175 mm / 0.125 in) and/or #030083

(0.953 mm / 0.037 in) as required.

1. Place jack stands under the fuel tank cradle.

2. While processing with one side at a time,

unscrew and remove the bolt.

FIGURE 20: TRANSVERSE SCREWS, 2 LOCATIONS

3. On the transversal screw joints (Figure 19)

any visible gap between cradle support tubing

and vehicle frame mounting lugs is not

acceptable.

4. The visible gap should be shimmed using U-

shims #030082 and/or #030083 as required.

5. Shim arrangement may vary and may be

stacked on both sides (Figure 21).

FIGURE 21: SHIM INSTALLATION, TRANSVERSE

SCREW. ARRANGEMENT MAY VARY

6. Replace any bolt showing signs of wear by

new hardware. DO NOT REUSE NUTS.

Perform replacement one screw location at a

time with appropriate support. Apply torque

seal mark.

Torque: 82 lb-ft (111 Nm)

Loading...

Loading...