SECTION 13: WHEELS, HUBS AND TIRES

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual | Section 13 revised Jan 2022

CAUTION

The actual length of thread engagement

present in an assembled wheel cannot always

be determined by visual inspection of

measurement of a tightened assembly. The

relationship of the wheel cap nut seat to the

end of the stud may vary. If there is any doubt

th

at enough thread engagement is present,

the number of engaged threads may be

counted. Tighten all nuts in the regular

manner, then loosen one to hand-tightness.

The number of turns to disengage a 1-1/8-inch

nut should be at least five full turns.

At least seven full turns should be required to

disengage a ¾-inch nut or a M22 nut. Ideally,

when torqued to the proper load, the stud

should be flush with the face of the nut. The

face of the nut may be recessed in nuts that

are taller for improved wrenching. With most of

the nuts in present use, a few unengaged

threads at the outer end will cause no problem

provided at least 5-7 full turns are required to

disengage the nut depending on thread size.

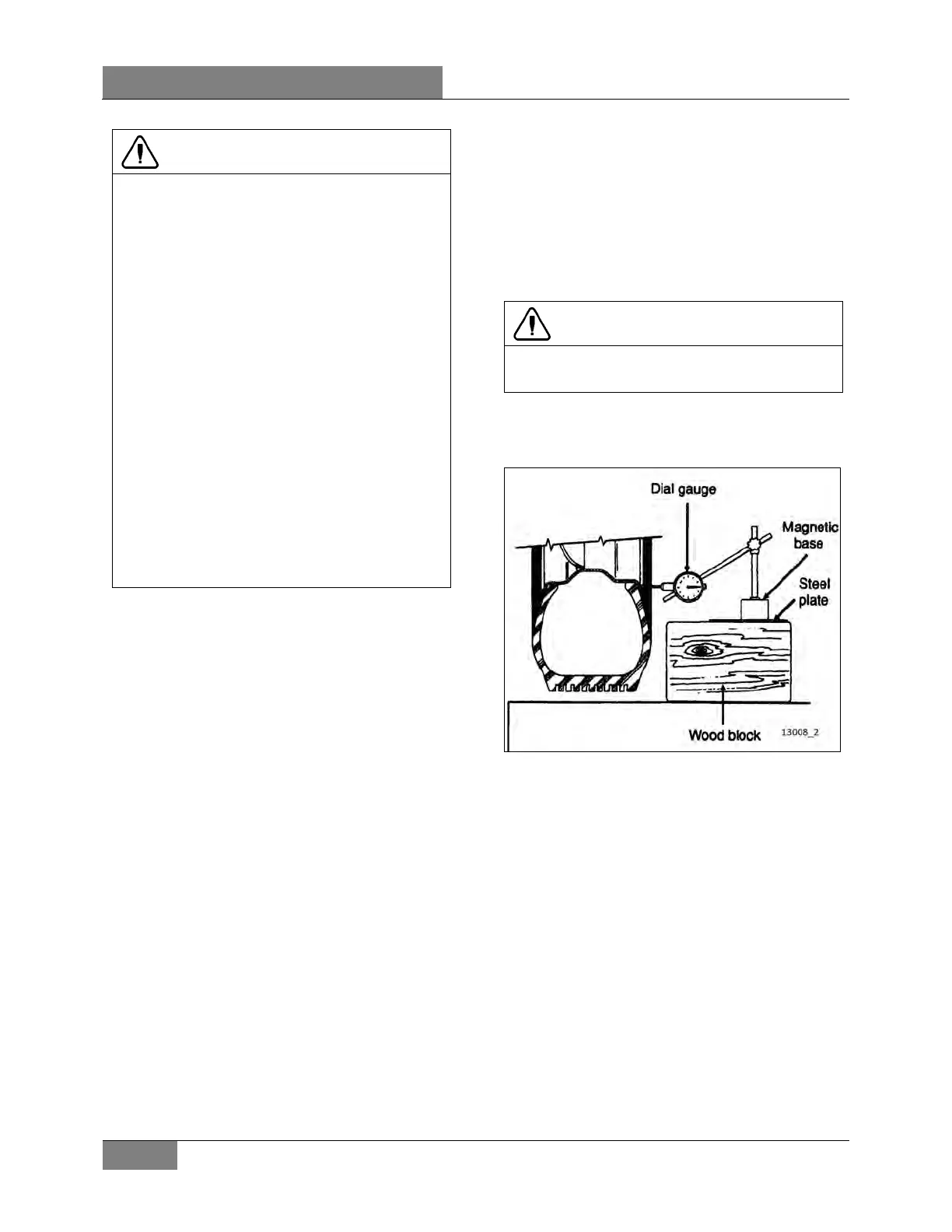

5. WHEEL STRAIGHTNESS TEST

1. Slightly raise axle to be checked and place a

safety support underneath;

2. Check wheel lateral run-out. Install a dial

gauge as shown in figure 4, then rotate the

wheel by hand one full turn. As the wheel

turns, note any variation on the dial gauge;

CAUTION

Damage to the dial gauge could occu

strikes a wheel balancing weight.

3. If the variation in lateral run-out exceeds

0.0625 inch (1,6 mm), the wheel must be

replaced.

FIGURE 3: DIAL GAUGE INSTALLATION

If doubt exists whether wheel or hub is distorted,

hub may be checked as follows:

• Replace the existing wheel with a wheel

known to be correct;

• Check wheel lateral run-out as outlined in

step 2;

• If, within specifications, the hub is correct

but the suspected wheel must be replaced.

Loading...

Loading...