SECTION 12: BRAKE AND AIR SYSTEM

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual Section 12 revised Jan 2021

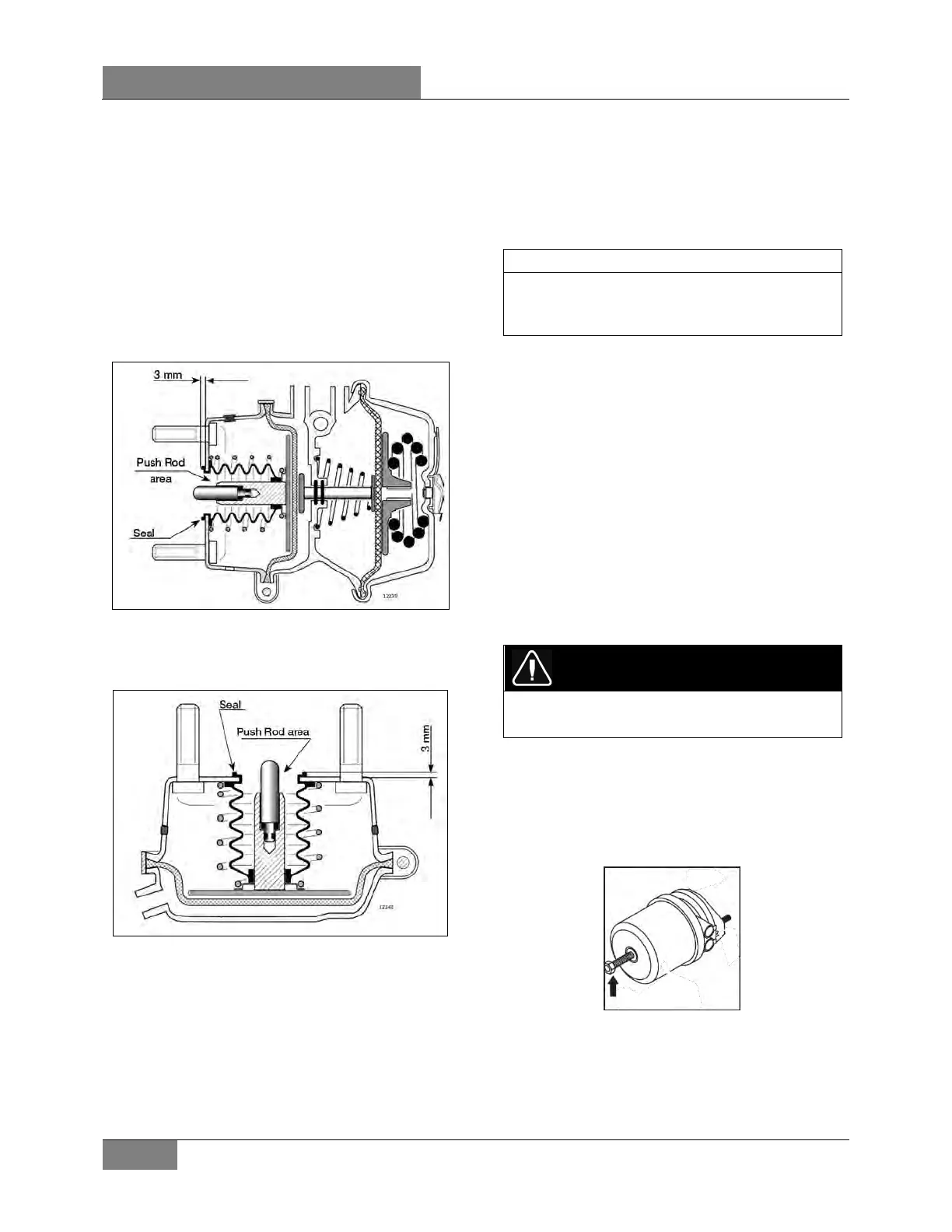

19. BRAKE CHAM BER

This vehicle uses Knorr-Bremse brake

chambers on all axles. The drive axle chambers

consist of two separate air chambers, each

having its own diaphragm and push rod. They

are used as a service brake chamber, an

emergency brake in case of air pressure loss

and a spring-applied parking brake. Refer to

FIGURE 55.

FIGURE 55: DRIVE AXLE BRAKE CHAMBER

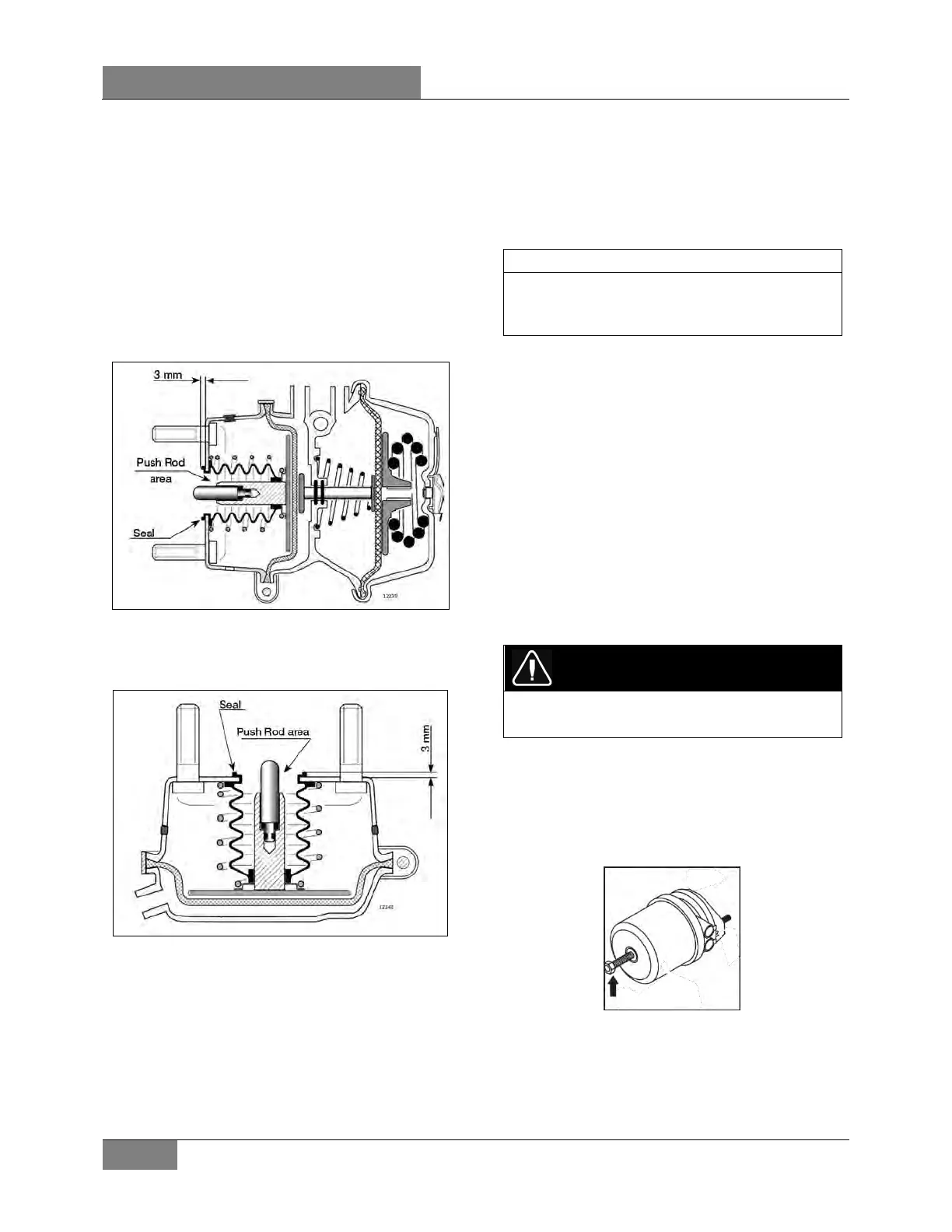

The front and tag axle brake chambers are used

only for service brake duty (FIGURE 56).

FIGURE 56: FRONT AND TAG AXLE BRAKE CHAMBER

19.1 MAINTENANCE

Every 6,250 Miles or twice a year, whichever

comes first depending on type of operation:

Check all hoses and lines. They should be

secure and in good condition.

Every 100,000 Miles or once a year, whichever

comes first depending on type of operation:

1. Disassemble and clean all parts.

2. Install new diaphragm or any other part if

worn or deteriorated.

When the diaphragm, spring, or both are

replaced, they should be replaced in the

corresponding chamber on the same axle.

3. Perform an airtightness test:

a) Make and hold a full brake application.

b) Coat clamping ring(s) with a soapy solution.

If leakage is detected, tighten clamping ring

only enough to stop leakage. Do not

overtighten as this can distort sealing

surface or clamping ring. Coat area around

push rod hole (loosen boot if necessary).

No leakage is permitted. If leakage is

detected, the diaphragm must be replaced.

19.2 EMERGENCY/PARKING BRAKE

MANUAL RELEASE

DANGER

Never stand in the axis line of the spring brake

actuators, especially when caging the spring.

Drive Axle

1. Block the wheels to prevent the vehicle from

moving.

2. Remove the release stud tool from its

storage place on drive axle brake chamber.

3. Remove the access plug from the end of the

spring chamber, and then insert the release

stud through the opening. Turn the release

stud 1/4 turn (clockwise) to anchor it into the

spring plate. Install the flat washer and nut,

Loading...

Loading...