SECTION 09: PROPELLER SHAFT

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

BEARING RETAINER BOLT TORQUE (HALF

ROUND)

6. Grease the U-joint and slip member after

propeller shaft installation. Refer to 4.1

LUBRICATION PROCEDURE.

6.3 UNIVERSAL JOINT INSTALLATION

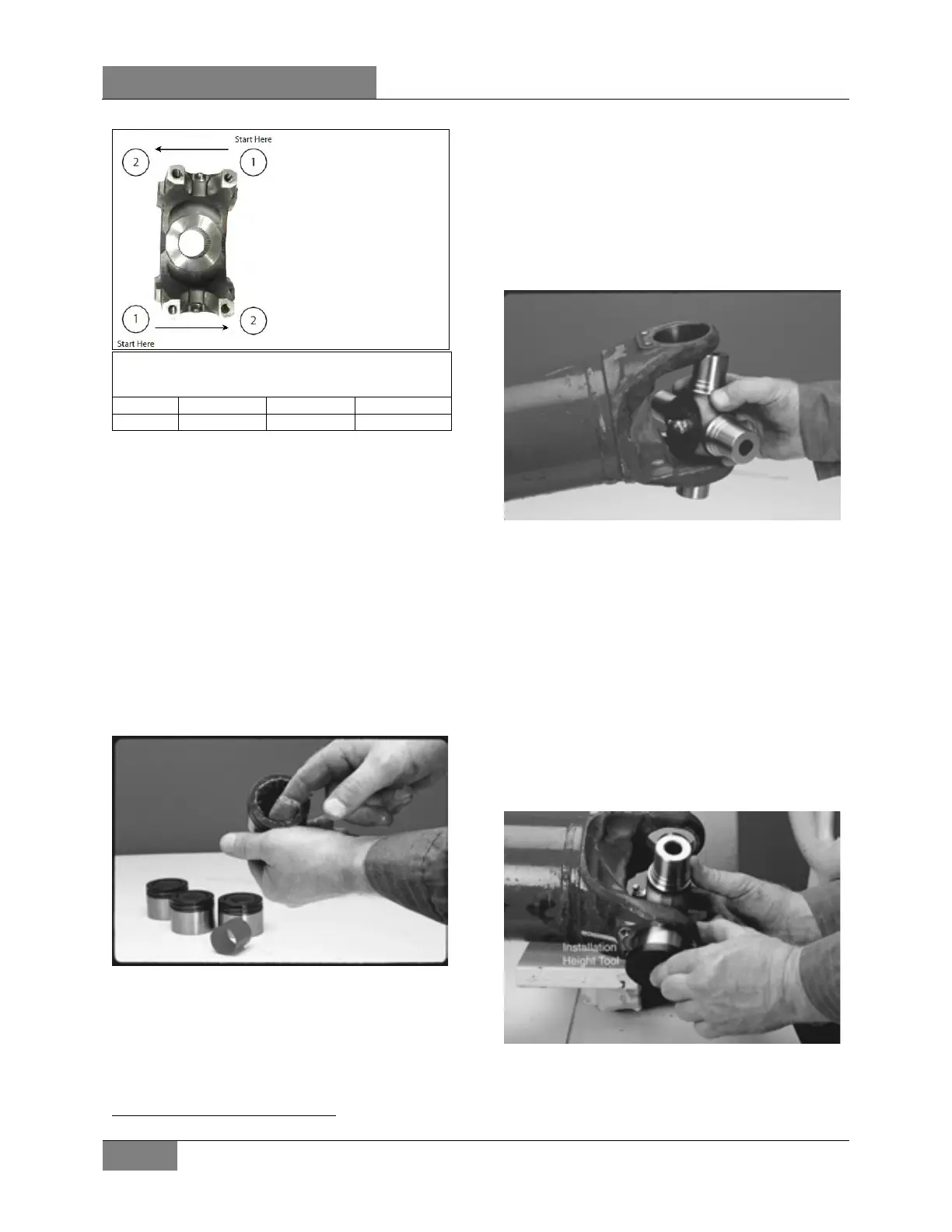

1. Remove needle retaining plugs from all

bearing cup assemblies. Using a high quality

National Lubricating Grease Institute E. P.

Grade 2 lubricating grease, wipe each

bearing cup assembly with grease. Fill all

cavities between the needle rollers. Also

apply a liberal coating of grease on the

bottom of each bearing cup assembly and

on the lip of the seal.

FIGURE 27: GREASING BEARING CUP

Caution - Spicer DOES NOT recommend

wiping the outside of bearing cup assemblies

or yoke cross holes with grease, oil or

silicone-based sprays. This could result in

bearing cup assembly rotation in yokes.

1

Prevost production line torque value

2. Position the journal cross into the yoke cross

holes with the grease zerk fitting inward

toward tubing. The double-headed, grease

zerk (nipple) fitting should be perpendicular

to the yoke cross holes.

Note: Failure to properly position the

universal joint will result in the inability to

grease the universal joint.

FIGURE 28: POSITION THE JOURNAL CROSS INTO THE

YOKE CROSS HOLES WITH THE GREASE ZERK

FITTING INWARD TOWARD TUBING

Note: Always inspect bearing cups for rollers

that may have fallen (downed rollers) out of

place before installation.

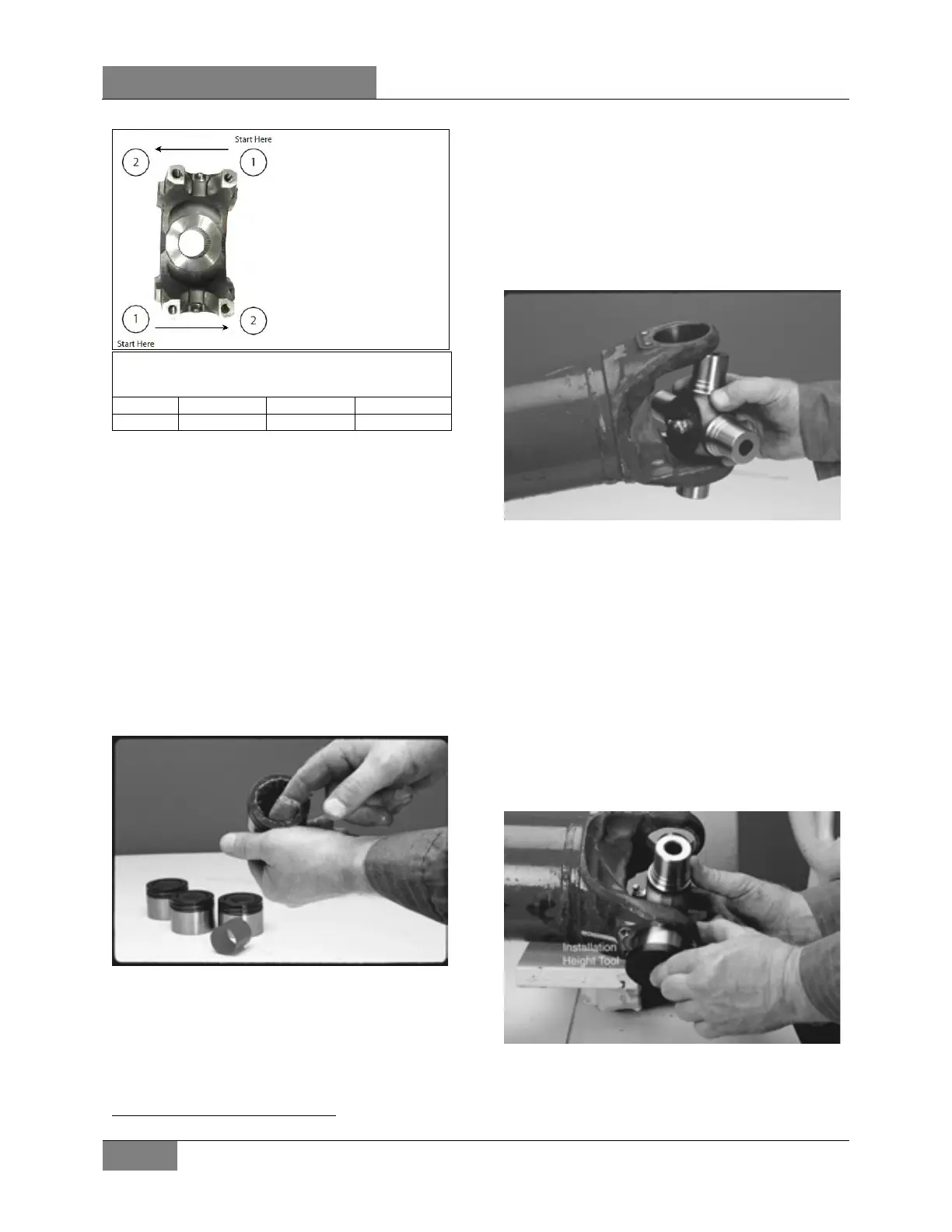

3. Move one end of the journal cross to cause

a trunnion to project through the cross hole

beyond the outer machined face of the yoke

ear. Take one bearing cup assembly and

position an installation height tool on the end

of the bearing cup assembly. Place the

bearing cup assembly over the protruding

trunnion diameter and align it to the yoke

cross.

FIGURE 29

4. Align the yoke in an arbor press with the

bearing assembly resting on the base of the

press. Cover the yoke ear with a metal plate

Loading...

Loading...