DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual Section 11 revised Jan 2021

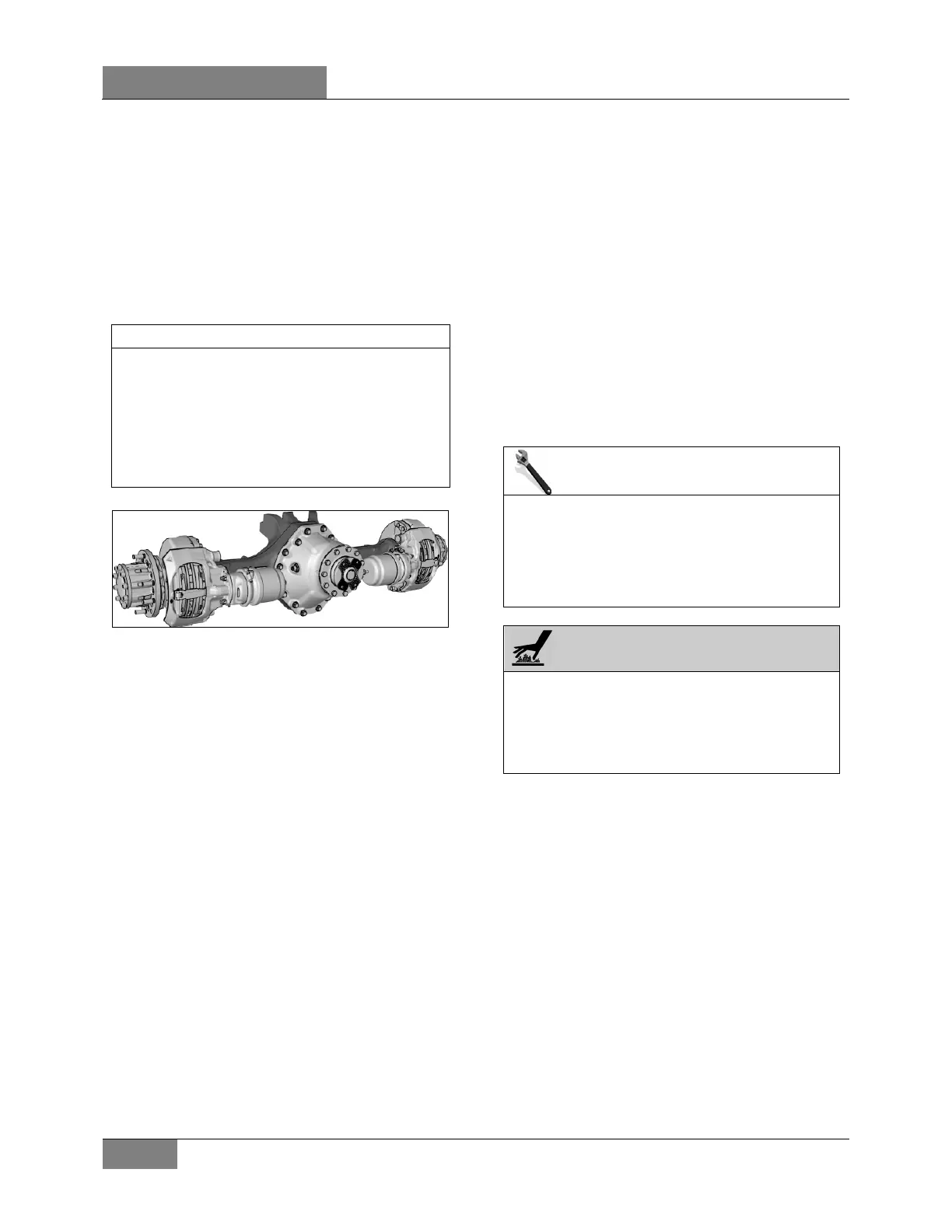

2. ZF A132 DRIVE AXLE

This vehicle is equipped with a ZF model A132

Hypoid Single Reduction drive axle, fitted with

two Knorr Bremse brake chambers, Knorr

Bremse SN7 disc brake and companion flange

for Dana Spicer SPL250 propeller shaft. Visual

brake wear indicator and a potentiometer wear

indicator are installed. The carrier gear ratio is

3.82.

Additional information is found in the following

manuals, included on your vehicle technical

publications USB drive:

•

OPERATING INSTRUCTIONS ZF AXLE A132

(version with US hub) #5871 207 982 EN.

• ZF AXLE A132 REPAIR MANUAL #5871 207 002E

FIGURE 1: ZF A132 DRIVE AXLE 11019

2.1 MAINTENANCE

Proper vehicle operation starts with preventive

maintenance, which includes adequate

operation of the differential.

The most common causes of drive axle failures

are spinout, shock, fatigue, overheating and lack

of lubrication. Monitor these conditions as they

could be the first steps leading to improper

maintenance, expensive repairs, and excessive

downtime.

Inspect at the pinion oil seal, axle shaft flange

and carrier housing joint for evidence of lubricant

leakage. Tighten the bolts and nuts, or replace

the gaskets and seals to correct leaks.

Maintenance of the axle mountings consists

primarily in a regular and systematic inspection of

the radius rods, as directed in Section 16,

"Suspension".

2.1.1 Differential Oil Type

Use Mobil Delvac Synthetic Gear Oil 80W-

140 (ZF lubricant class 12M). Other approved

lubricants may be use. Additional lubrication

information is covered in ZF’s list of lubricants

TE-ML 12.

2.1.2 Checking and Adjusting the Differential

Oil Level

1. Place the vehicle on a level surface.

2. Level check plug must be cleaned carefully

before opening.

3. Check oil level at room temperature only.

MAINTENANCE

Oil level check

Check differential oil level and add if

necessary

at the intervals specified by the

Lubrication And Servicing Schedule in

Section 24A.

WARNING

Check the oil level when the axle is at room

temperature. When hot, the oil temperature

may be 190ºF (88ºC) or more and can cause

burns. Also, a correct reading is not obtained

when the axle is warm or hot.

4. Make sure the axle is at room temperature.

5. Clean the area around the level check plug.

Remove the level check plug from the

differential case.

6. The oil level must be even with the bottom of

the level check bore.

7. If oil flows from the hole when the plug is

loosened, the oil level is too high. Let drain

the oil to the correct level.

8. If the oil level is below the bottom of the level

check bore, add the specified oil through the

level check bore.

9. Reinstall the level check plug using a new

seal (O-ring).

Tighten to 52 lb-ft (71 Nm)

Loading...

Loading...