DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

2. DESCRIPTION

The vehicle is equipped with an Allison B500

automatic transmission

2.1 ALLISON AUTOMATIC TRANSMISSION

The Allison Transmission has 6 speeds with two

top range (fifth and sixth) overdrives.

An electronic control allows the transmission to

shift at exactly the right point on the engine's fuel

consumption curve for best economy. Early

lockup maintains the highest possible mechanical

efficiency through the closely-spaced gear steps,

culminating in two overdrive ratios. This

combination allows progressive shifting

techniques, where engine speeds are reduced for

higher efficiency and lower fuel consumption.

FIGURE 1: ALLISON TRANSMISSION (07075)

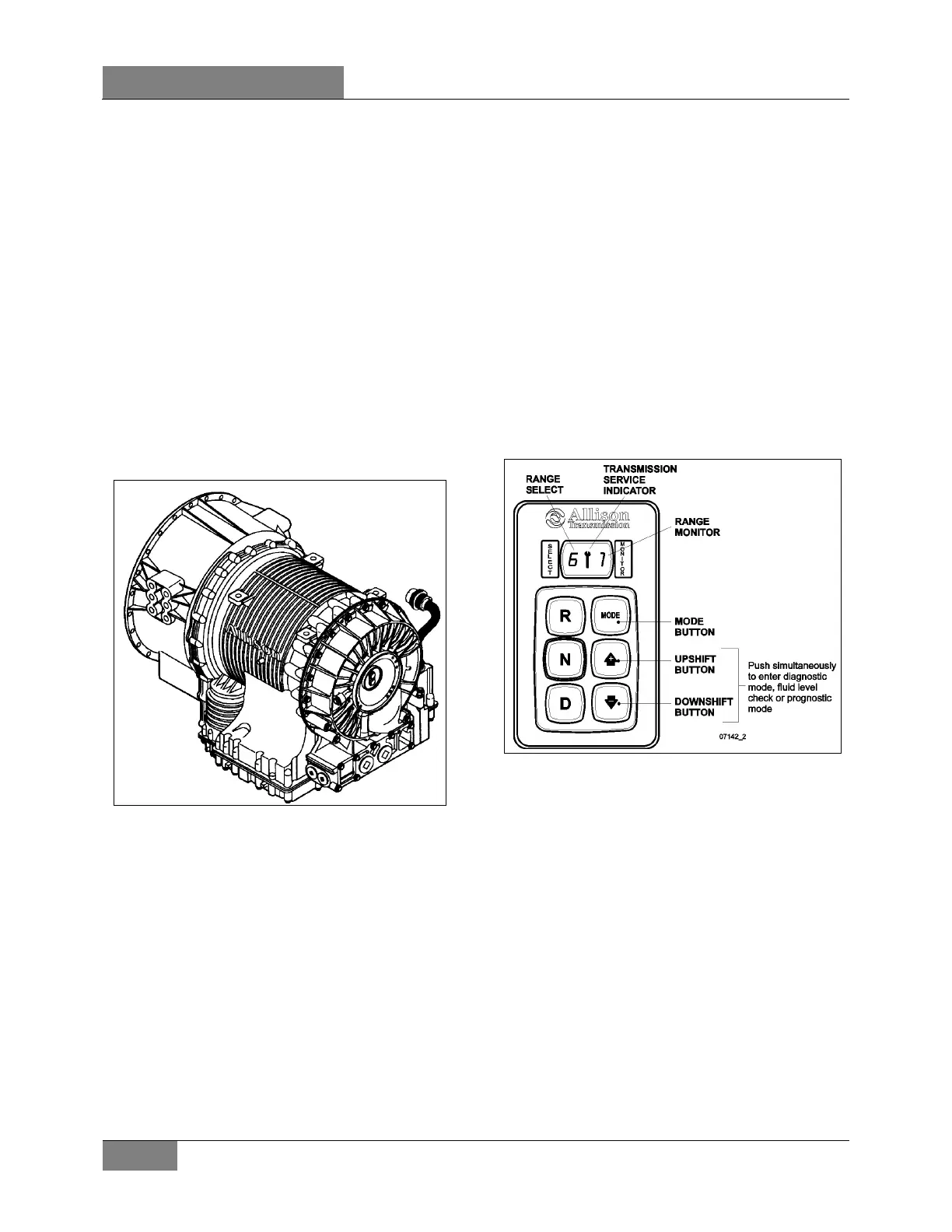

Gear selection and torque converter modes are

controlled by a microcomputer-based electronic

transmission management system. It is fed

information regarding throttle position, operator

range selection, engine speed, turbine speed,

transmission output speed and various system

pressures from special electronic sensors. With

this information, it computes shift points and

clutch pressures to meet immediate needs.

Using closed loop adaptive logic, the electronic

control looks at a number of parameters during

the shift, and makes minute adjustments to

match the shift to desired profile stored in its

memory. It then looks at these adjustments and

resets the parameters, which allow the

transmission to quickly compensate for

variations in load, terrain or environment and to

adjust for clutch wear and engine power changes.

A Diagnostic Data Reader can be connected to

the electronic control unit to provide a self-check

of all systems in the transmission. Five-digit

trouble codes greatly reduce the time it takes to

pinpoint potential problems. (Refer to paragraph 7

“Allison transmission troubleshooting” in this

section).

2.1.1 Retarder

This auxiliary braking device for the automatic

transmission is integrated into the basic envelope

of the transmission and transmits its braking force

directly to the propeller shaft. It requires no

additional length and adds only 75 pounds (34 kg)

of weight. Operation of the retarder is controlled

electronically by the driver's use of the brakes.

FIGURE 2: ALLISON PUSHBUTTON SHIFT SELECTOR

When activated, fluid enters a cavity and provides

resistance to the turning of rotor blades revolving

with the output shaft. This effectively slows the

vehicle to the point where the service brakes are

needed only for final stopping. The retarder is fully

modulated and is compatible with ABS.

3. ALLISON TRANSMISSION

MAINTENANCE

3.1 MANUAL FLUID LEVEL CHECK

To gain access to the dipstick, open the engine

compartment rear door; dipstick is located on the

radiator side of the engine (Figure 3).

Clean all dirt from around the end of the fluid filler

tube before removing the dipstick. Dirt or foreign

matter must not be permitted to enter the fluid

Loading...

Loading...