SECTION 13: WHEELS, HUBS AND TIRES

D DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual | Section 13 revised Jan 2022

6. WHEEL STUDS

Stripped threads may be the result of excessive

torque or may have been damaged during wheel

installation when placing the wheel over the

studs. A stud having damaged threads must be

replaced. Broken studs are a direct result of

operating with loose stud nuts or improperly

seated wheels. When a broken stud is replaced,

the adjacent studs, on each side of the broken

one must also be replaced since they could

have been subjected to excessive strain and

may be fatigued.

When installing wheel studs to hubs, check nuts

retaining the wheel stud to wheel hub and

replace if they are deformed, damaged or

severely corroded. Install nut (and washer where

applicable) to new stud.

TORQUE: 450-500 lb-ft (610-678 Nm)

60 nuts

6.1 DRIVE AXLE WHEEL STUDS

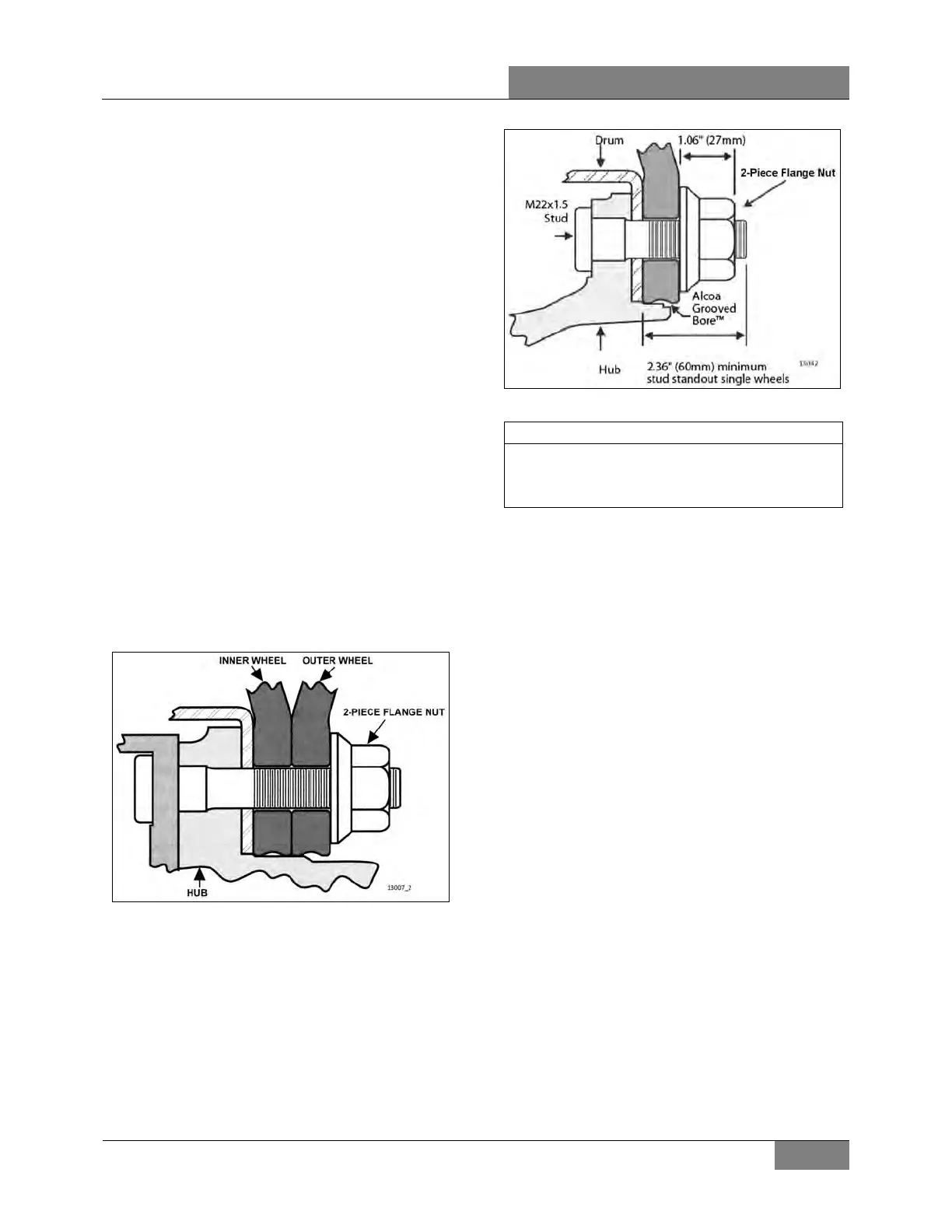

Hub-mounted wheels are mounted with M22x1.5

studs and an M22 flange nut.

FIGURE 4: DRIVE AXLE WHEELS

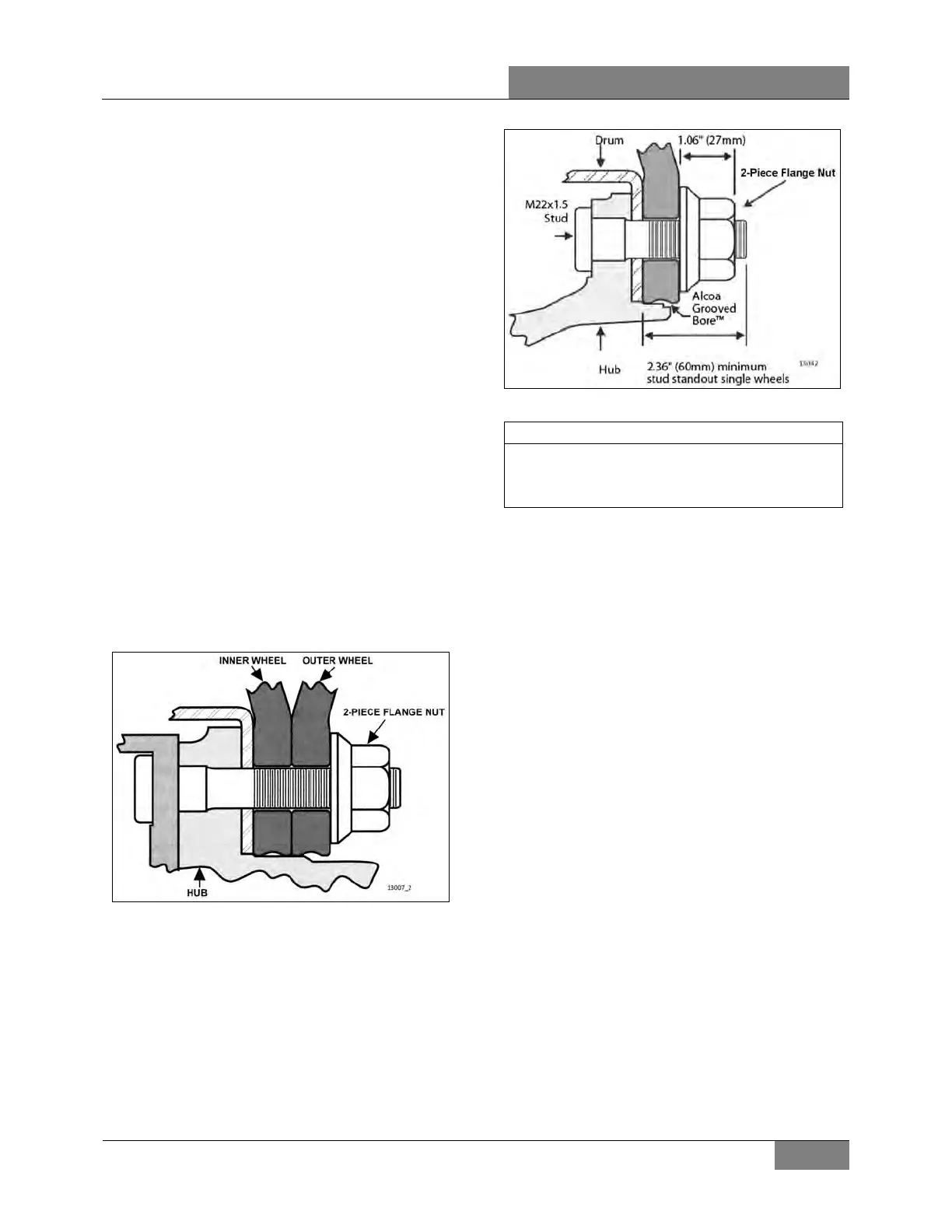

6.2 FRONT AND TAG AXLE WHEEL STUDS

Wheel is hub mounted on front and tag axle

(M22x1.5 thread).

FIGURE 5: SINGLE WHEEL

Wheel studs and nuts must be kept free from

grease and oil. No lubricant whatsoever

should be used.

Loading...

Loading...