DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

2. Exhaust compressed air from accessory air

tank by opening drain cock under reservoir.

3. Disconnect the height control valve link and

pull down the control arm to ensure all air is

exhausted from air springs.

While performing this step, do not change the

height control valve control arm adjustment.

4. Disconnect air line from air spring, remove

elbow (if applicable), and cover both the line

end and fitting to prevent the entry of foreign

matter.

5. Unscrew the two air spring lower mounting

nuts.

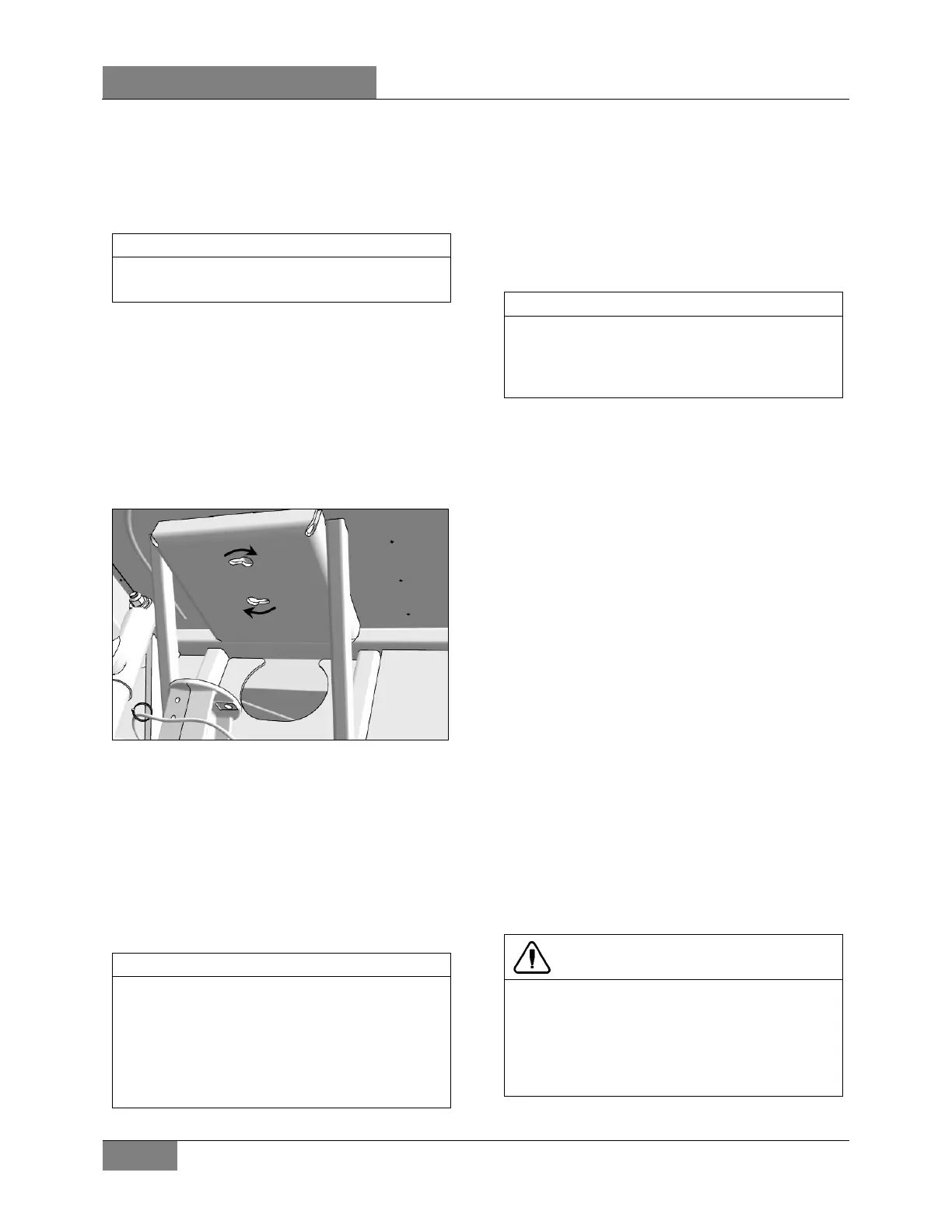

6. Rotate the air spring clockwise (Figure 3) to

free the upper attachments from the

mounting plate.

7. Remove the air springs.

FIGURE 3: AIR SPRING UPPER MOUNTING PLATE

3.1.3 Installation

1. Compress air spring as necessary and

position air spring between both the lower

and upper mounting plates.

2. Align the upper attachments with holes in the

mounting plate. Rotate air spring

counterclockwise.

3. Thread the lower nuts a few turns.

To facilitate air spring installation, compress it

manually then put a piece of tape over the air

line threaded fitting. This prevents air from

getting back into the air spring

compressed, thus enabling to place the air

spring

in between the mounting plates and

greatly easing installation.

4. Tighten and torque the lower stud nuts.

TORQUE: 31-38 lb-ft (42-52 Nm)

5. Install elbow (if applicable), then connect air

line.

6. Connect the height control valve link.

7. Build up air pressure in system.

To accelerate this operation, air reservoirs can

be filled from an exterior air supply connected

to the accessory tank fill valve or to the

emergency fill valve.

7. Check operation of bellows and with the

primary air system at normal operating

pressure (122 - 140 psi (841 - 965 kPa)),

coat the air line connections and air spring

mounting areas with a water and soap

solution. Bubbles will indicate an air leak,

and none is permissible. Repair or replace

defective parts.

8. Reinstall wheel.

9. Remove the hydraulic floor jack from under

the axle, then lower vehicle to ground.

3.2 SHOCK ABSORBERS

Double-action, telescoping-type shock absorbers

ensure a smooth ride and enhance vehicle

stability on the road. All shock absorbers are

eye-type mountings. The front and tag axles are

each provided with two shock absorbers while

the drive axle is provided with four of them.

Shock absorbers are non-adjustable and non-

repairable. Maintenance requirements involve

replacement of the rubber mounting bushings,

and tightening of all shock absorber pins

according to Torque Table when shock absorber

replacement occurs. If a shock absorber

becomes inoperative, complete unit must be

replaced.

CAUTION

When a shock absorber is found defective,

always replace

with a new set on affected

axle, except if there has been a recent

replacement of one unit. The following method

will help in determining if both shock absorbers

on the same axle have to be replaced.

Loading...

Loading...