DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

CAUTION

Only the recommended jacking points must be

used as outlined in Section 18, "BODY".

For more clearance between the tag axle and

transmission, the tag axle may be unloaded and

jacked up.

3. Remove engine splash guards and protective

panels surrounding transmission.

4. Remove cross member from under

transmission.

5. Remove the transmission drain plug and allow

fluid to drain. Inspect the drain plug washer

and replace it if necessary. Reinstall the drain

plug (see "3.5 Fluid and Filter Change" in this

section.

TORQUE: 18-24 lb-ft (24-33 Nm)

WARNING

It is better to drain fluid when it is still warm.

Avoid contact with fluid since it can be very hot

and cause personal injury.

6. Remove transmission dipstick and filler tube.

7. Disconnect propeller shaft from transmission

and remove its safety guard. Refer to Section

09, "PROPELLER SHAFT".

8. Disconnect the two fluid cooler hoses from

transmission. Cover hose ends and fittings to

prevent fluid contamination.

WARNING

A significant amount of fluid may drain from

fluid lines when they are disconnected.

9. Disconnect all sensors on L.H. side of the

transmission.

10. Disconnect main wiring harness.

11. Disconnect the air supply line (steel-braided

hose) from retarder control valve.

12. Remove any locking tie, clamp and bracket

that may interfere with the removal of

transmission.

13. Support transmission using a suitable

transmission jack.

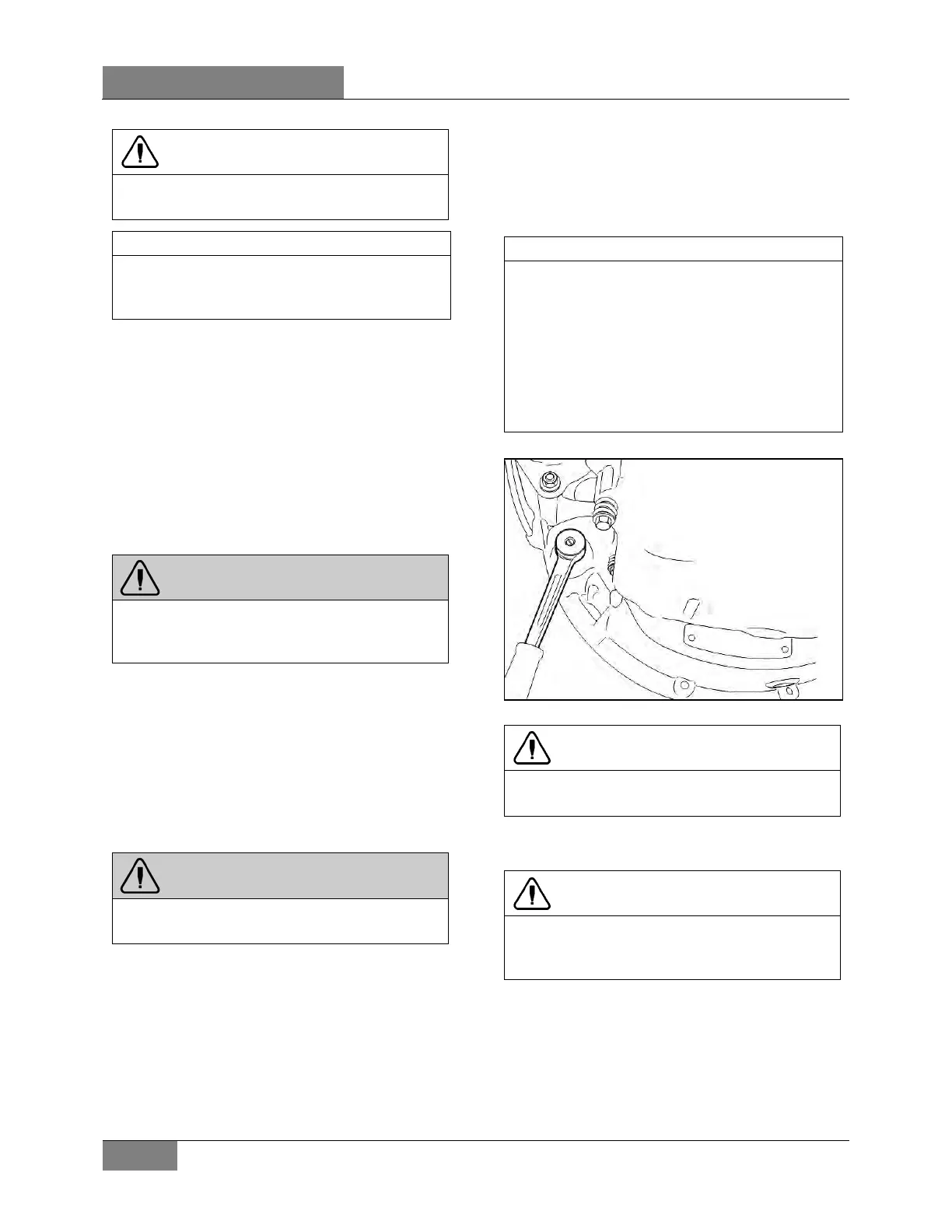

Remove starter motor located on engine L.H.

side. Removing the starter motor will allow

access to unfasten the 12 converter-to-flexible

plate att

aching screws. Remove the plug

located below starter motor and install cranking

tool (88800014). Cranking the engine to gain

access to the attaching screws may be done by

turning the cranking tool using a suitable

adapter (Figure 8).

FIGURE 8: VOLVO ENGINE CRANKING POSITION

CAUTION

Do not rotate alternator shaft clockwise to avoid

removing tension on belt.

14. Remove the 12 screws retaining the torque

converter housing to the flywheel housing.

CAUTION

Make sure transmission-to-engine alignment is

maintained when removing screws to avoid

damaging torque converter housing.

15. Slowly pull transmission straight out to clear

the engine.

16. Remove the transmission.

Loading...

Loading...