SECTION 13: WHEELS, HUBS AND TIRES

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual | Section 13 revised Jan 2022

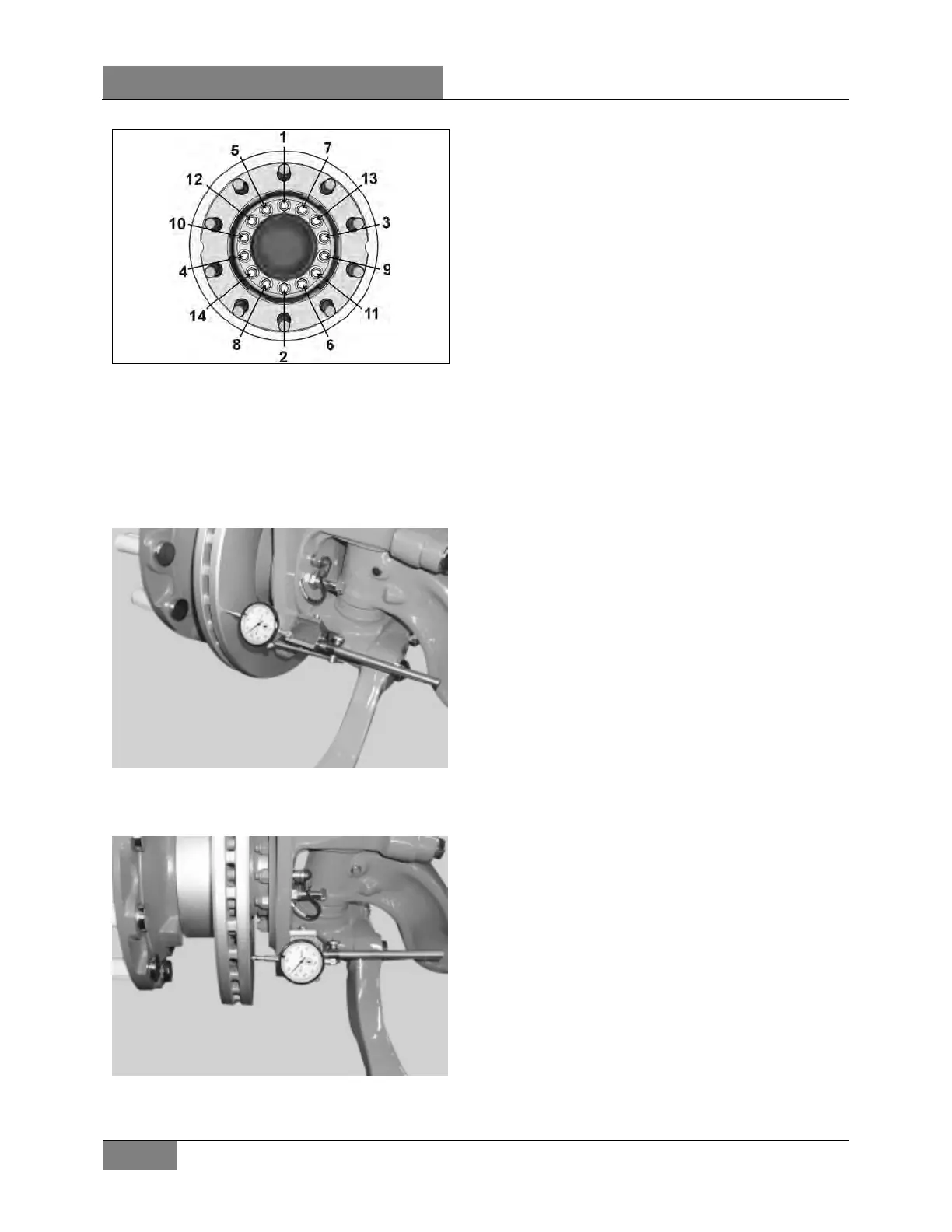

FIGURE 32 HUB FLANGE HEX CAP SCREW

TIGHTENING SEQUENCE

17. Once the hub flange has been correctly

fitted; it is necessary to check the axial run

out of the brake disc.

18. Position a dial test indicator onto the axle in

a suitable position.

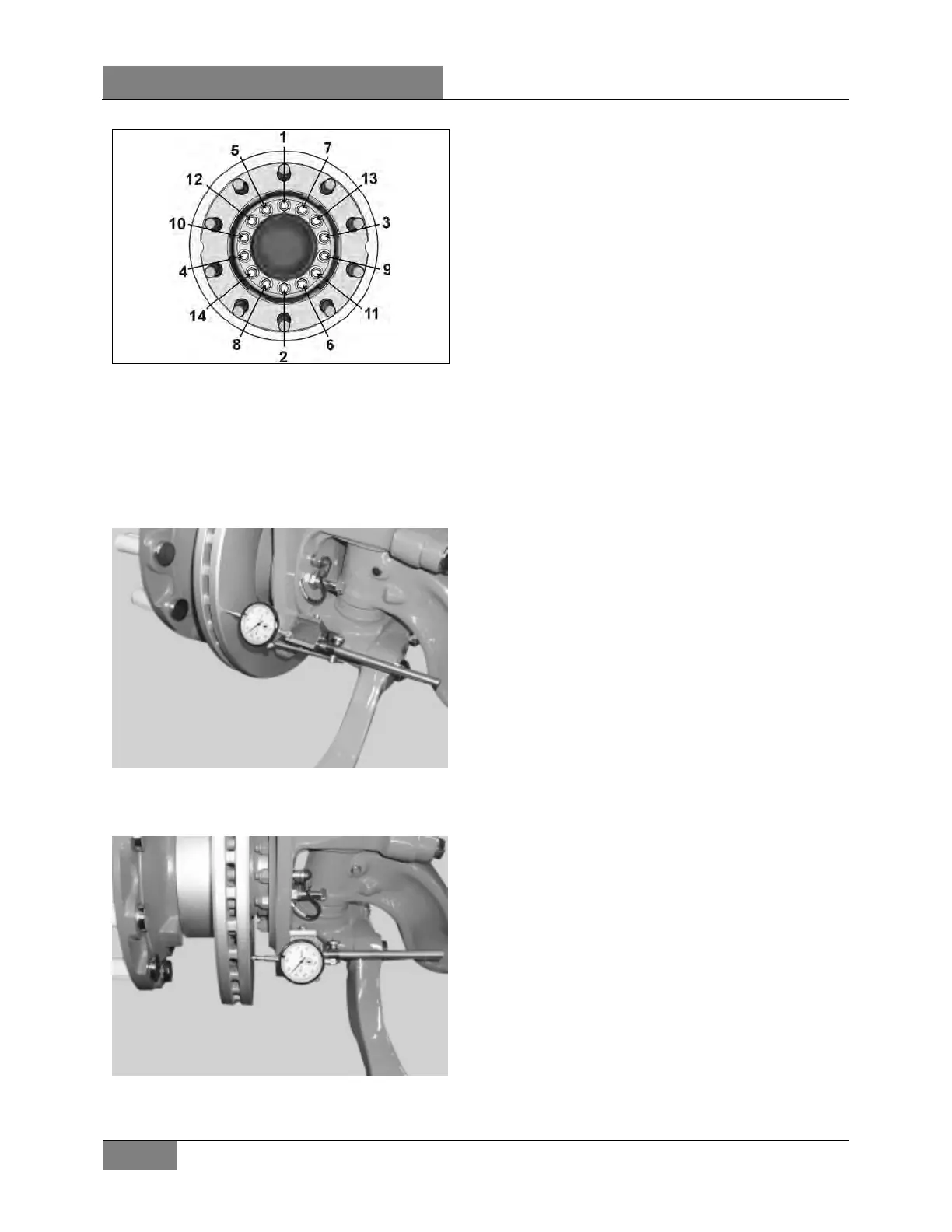

FIGURE 33

19. Position the stylus of dial test indicator onto

brake disc as shown.

FIGURE 34

20. Rotate the hub through 360° and note any

movement of the dial test indicator.

THE MAXIMUM RUNOUT IS 0.1 mm / 0.004 in

21. Remove and check out of specification disc

to ensure no damage has occurred to the

mounting faces, or that no dirt is present.

22. Remove any dirt found on the mounting

faces and refit and re check disc.

23. Should it be found that a cleaned and

refitted disc is still out of specification; it

must be replaced.

24. Mount the brake caliper. Refer to Knorr

Bremse manual.

25. Mount the wheel over studs, being careful

not to damage stud threads.

26. Screw in the hex stud nuts (refer to FIGURE

2 for sequence) so that wheel will position

itself concentrically with hub. This is

important, otherwise wheel may be eccentric

with hub and will not run straight. In this

initial step, slightly tighten the nuts to

correctly position the wheel.

27. Tighten stud nuts progressively as shown in

Figure 3. The final tightening should be done

with a torque wrench. Tighten stud nuts.

TORQUE: 450-500 lb-ft (610-678 Nm)

Loading...

Loading...