SECTION 22: HEATING AND AIR CONDITIONING

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual First release Oct 2020

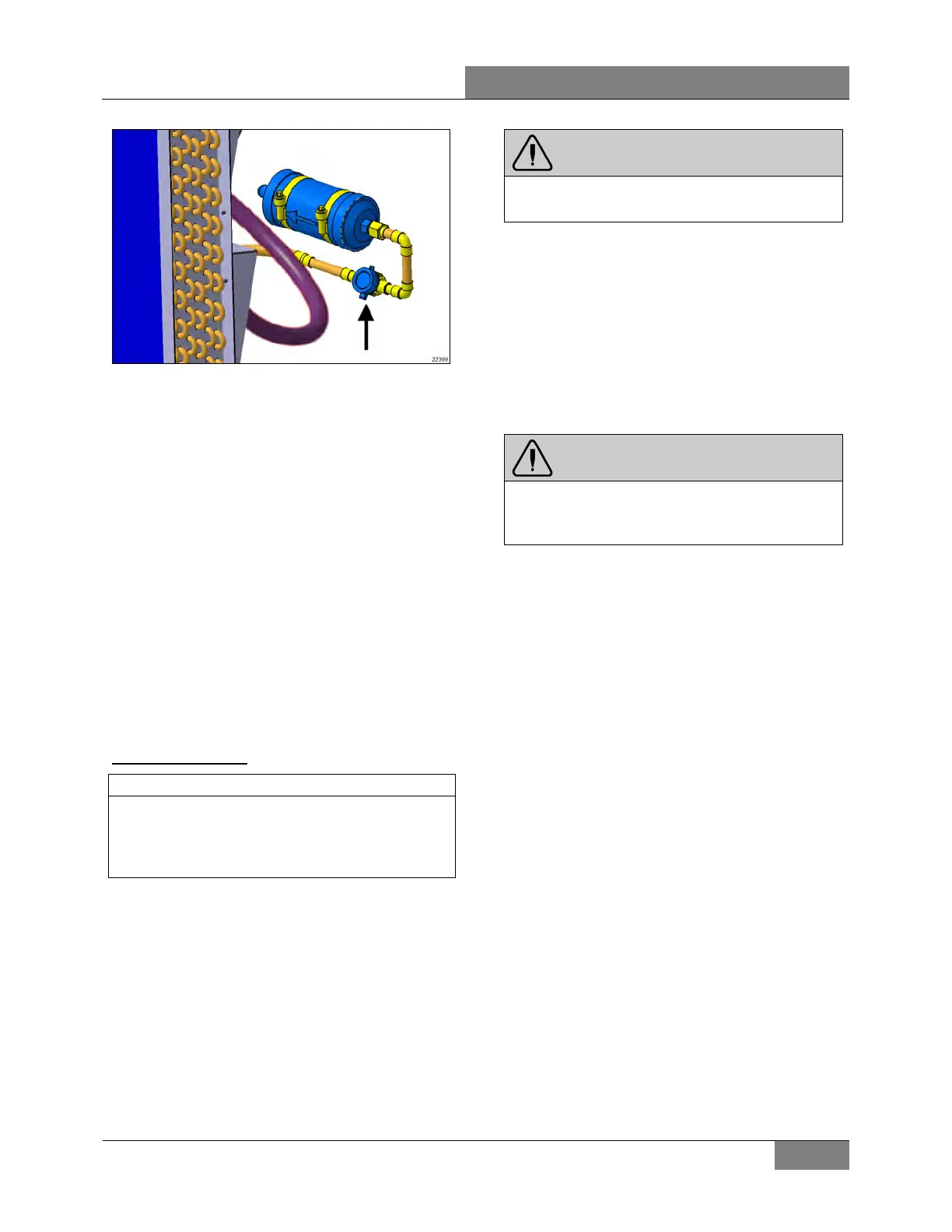

FIGURE 58: MOISTURE INDICATOR SIGHT GLASS

3- At fast idle, the high side pressure should

be near the following calculation: add 30° F

to the ambient temperature in Fahrenheit.

In the refrigerant chart (see 5.8

TEMPERATURES & PRESSURE CHART),

find this temperature and the corresponding

saturation pressure and add 10 psi for the

pressure drop between compressor and

condenser.

Calculation example:

At 70°F outside, add 30°F. In the chart

(paragraph 5.8 ), find the pressure value for a

temperature of 100°F. For R-134a refrigerant

gas, you will find a value of 124 psi. Add 10

psi to this value for the compressor to

condenser line, this result gives 134 psi. So a

high side pressure value between 129 to 139

psi should be OK.

Refrigerant addition

Use a bottle that is more than half full.

Alw

ays charge the system with the cylinder

upright and the valve on top to avoid drawing

liquid out of the cylinder.

1. Install a heated refrigerant bottle at the

back of the vehicle, on a scale, straight up.

Refer to section “Precautions in Handling

Refrigerant” for the proper heating method.

2. Connect the yellow hose of your manifold

gage set to the red (vapor) valve on the

bottle. Connect the blue valve of the gage

set on the suction shutoff valve service port

of the compressor. Connect the red valve of

the gage set to the discharge shutoff valve

service port. Hoses should be purged of air

at installation (evacuated).

WARNING

Secure manifold gage hoses so they will not

be damaged by engine belts and pulleys.

3. Midseat the compressor suction and

discharge shutoff valves.

4. In order to speed up the charging, unplug

the unloader to keep all compressor

cylinders active.

5. Let the door and hatches open and maybe

open side windows to prevent cooling down

the coach too rapidly. Preferably, the

interior would be hot, at least over 68°F.

WARNING

If discharge pressure is above 100 psig, the

condenser fans will be running. Keep hands

clear of fans

6. Start engine.

7. Switch to fast idle for faster fill and battery

protection.

8. Open the blue gage valve. The suction

pressure should go up meaning the

compressor is sucking from the tank also. If

there is almost no pressure rise, the tank is

too low or too cold.

9. Check the moisture indicator sight glass

and the discharge pressure to meet the

criteria described above.

10. When the sight glass gets clear, you can

add some reserve, up to 2 pounds, as long

as the high pressure does not move up.

11. When finished, close gage valves and

bottle valve.

12. Before stopping the engine, check the

compressor oil level and note it in the repair

book as well as the amount of refrigerant

added.

13. Shut down engine and backseat suction

and discharge shutoff valves (FIGURE 56).

MAX TORQUE: 12 lb-ft (16 Nm)

14. Remove gages and replace caps.

15. Perform a road test for final verification.

Loading...

Loading...