12 Injection Port

12.2

12.

112

GC-2010 Plus

12.2Glass Insert and Packing Requirements

It is necessary to pack silica (glass) wool into the glass insert (liner) in order to sufficiently mix the

vaporized sample and to prevent high-boiling point compounds from contaminating the capillary

column.

Q Quantity of silica wool

Quantity of silica wool (standard) = Approx. 10 mg (for split)

= Approx. 2 mg (for splitless/WBI)

= Silica wool is not necessarily required when making direct

injections. However, if the sample contains non-volatile

compounds, less than 5 mg of silica wool can improve the

chromatography.

NOTE For special samples, better results may be obtained by varying the amount of silica wool in the insert.

(1) Reduce the amount of silica wool for highly absorptive samples, such as agricultural samples.

(2) Increase the amount of silica wool when injecting solvents with a high latent heat of vaporization,

such as water.

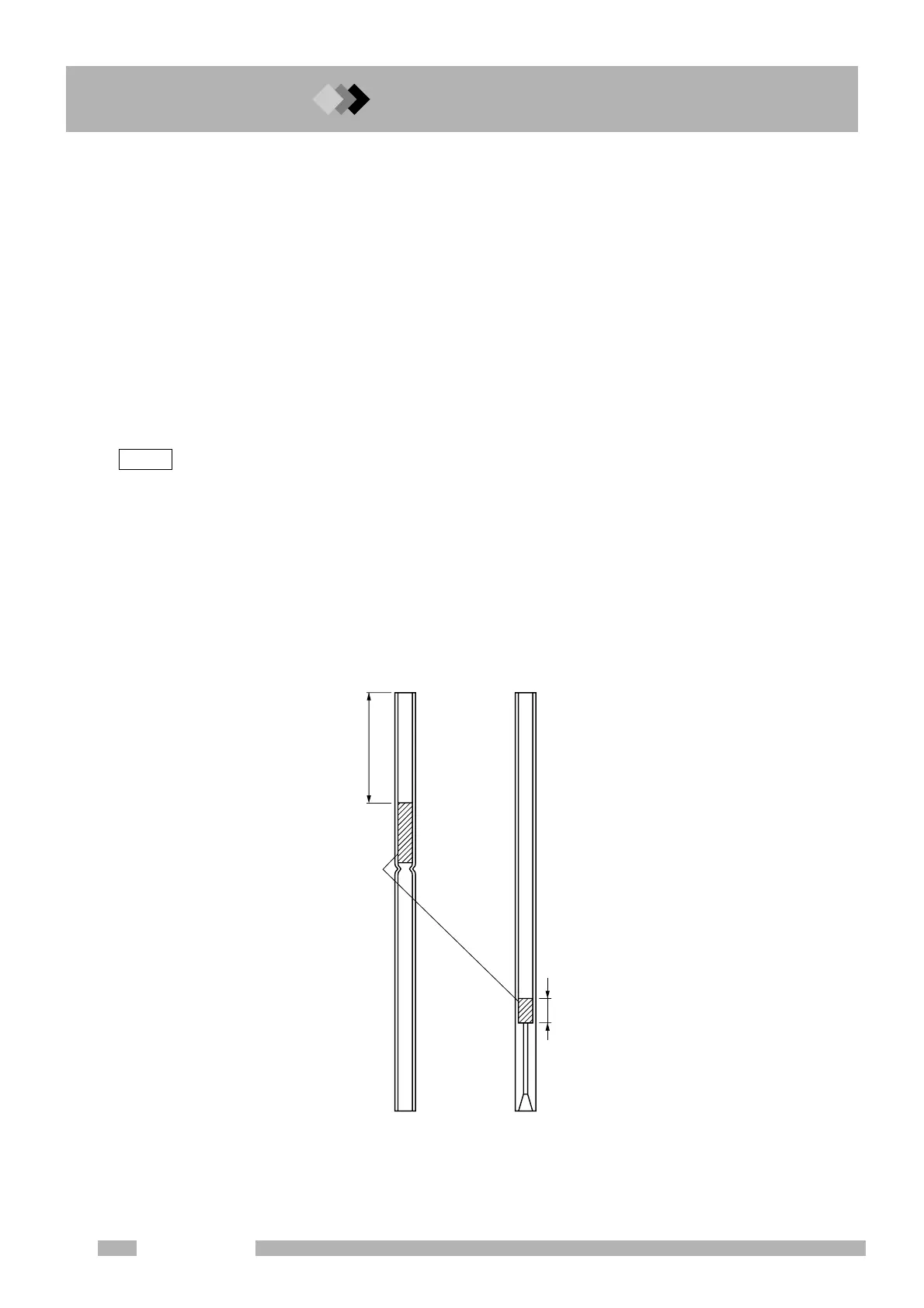

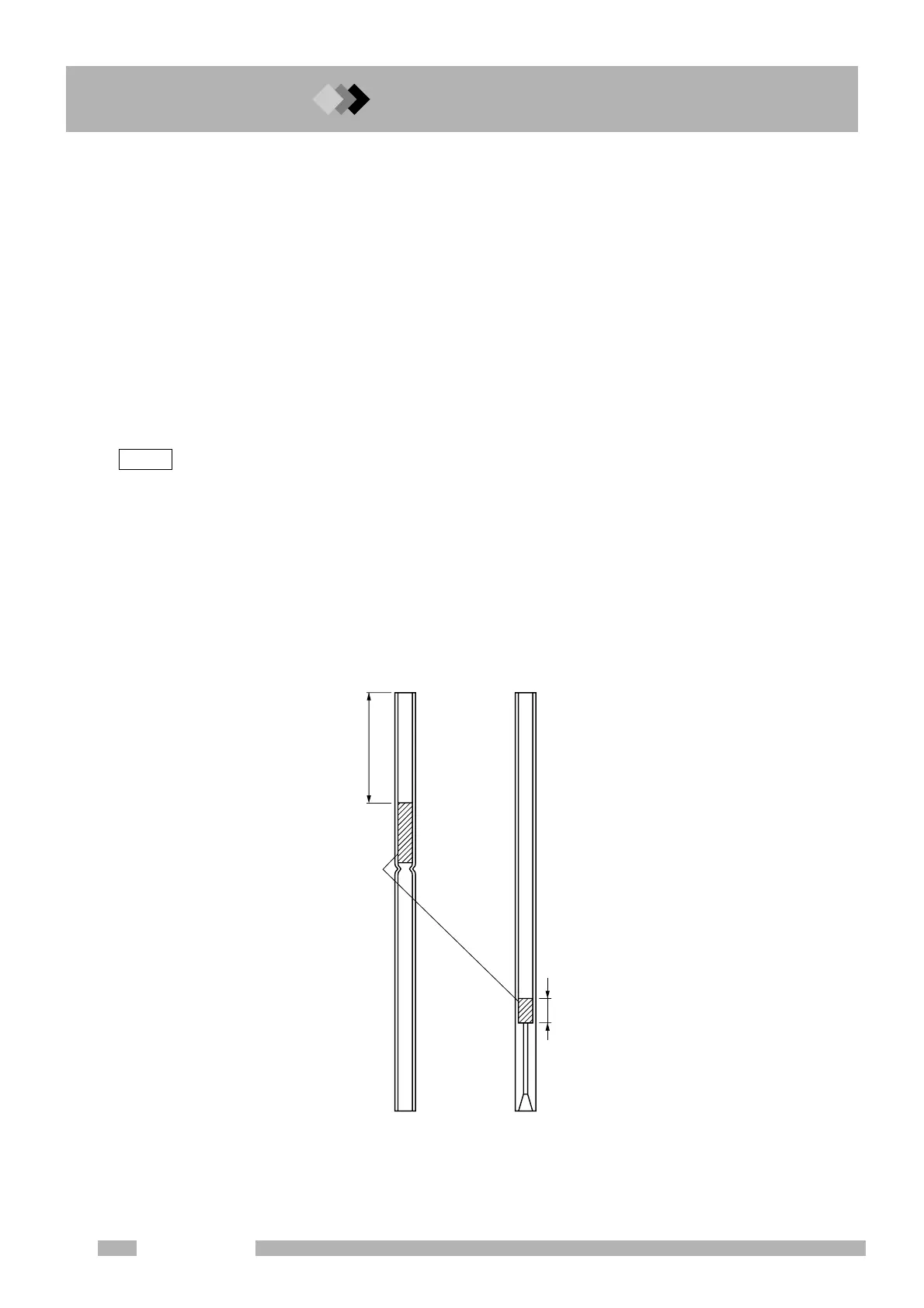

Q Position of silica wool

Split and splitless glass insets are shaped differently, as shown below. Place the silica wool

1−2 mm below the lowest point of the needle at injection. For split analysis, if the wool is too

close or too far away from the needle, good reproducibility of results may not be obtained.

For splitless analysis, place the wool at the bottom of the glass insert.

The recommended position of silica wool for each insert is shown below.

Fig. 12.2.1 Silica wool position for split and splitless inserts (AOC-20i)

25 mm

Silica wool

For split analysis For splitless/WBI analysis

5.5mm

Loading...

Loading...