19 Troubleshooting

19.1 Troubleshooting

314

GC-2010 Plus

19.1.4 Chromatogram and data

19.1.4.1 No peaks or extremely small peaks

Peaks may not be able to be detected because of high noise.

Refer to 19.1.3.1.3 and 19.1.3.2.3, “baseline noise is high.”

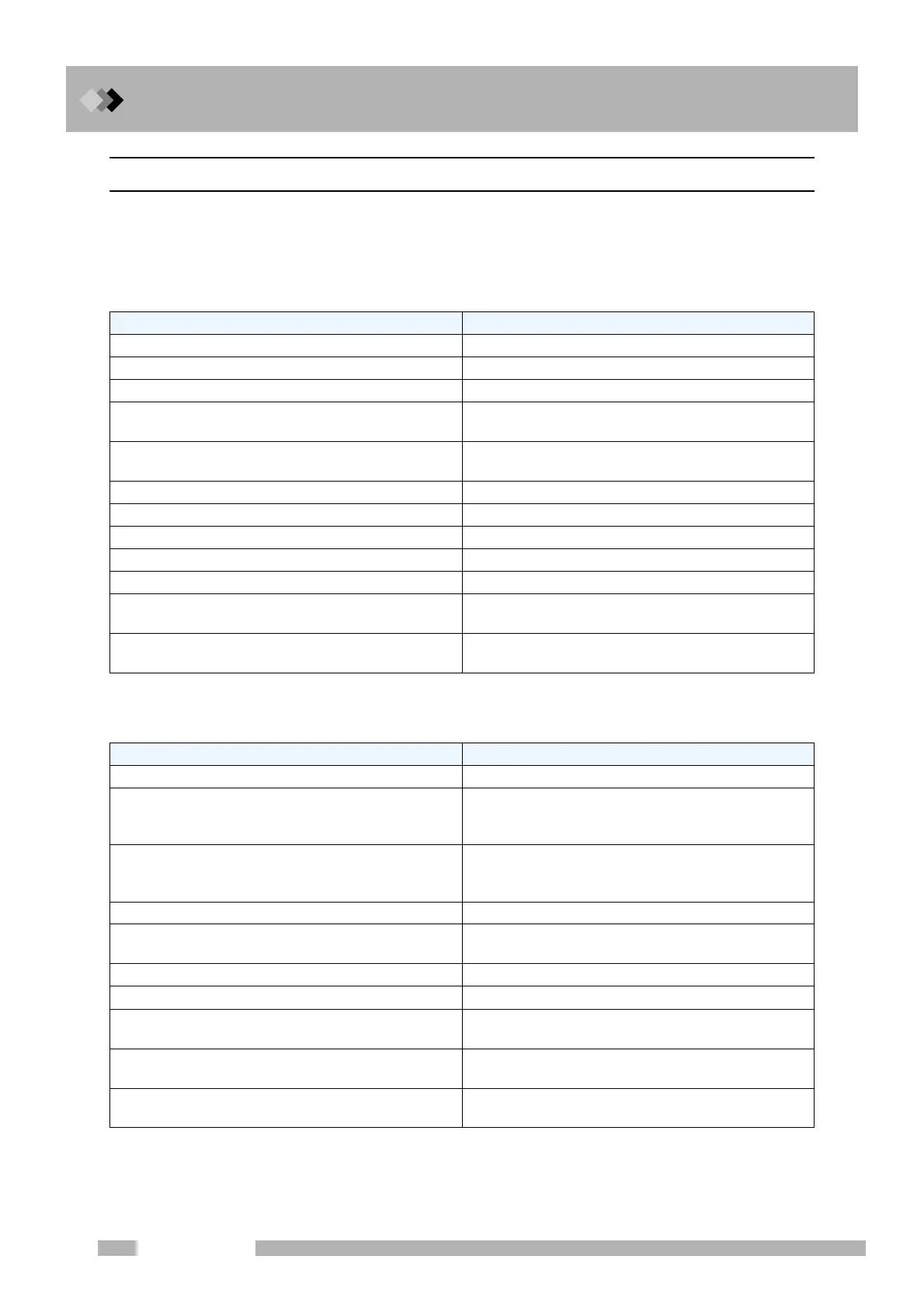

FID detector

If the jet or the cable is damaged, contact your Simadzu repretetative for replacement.

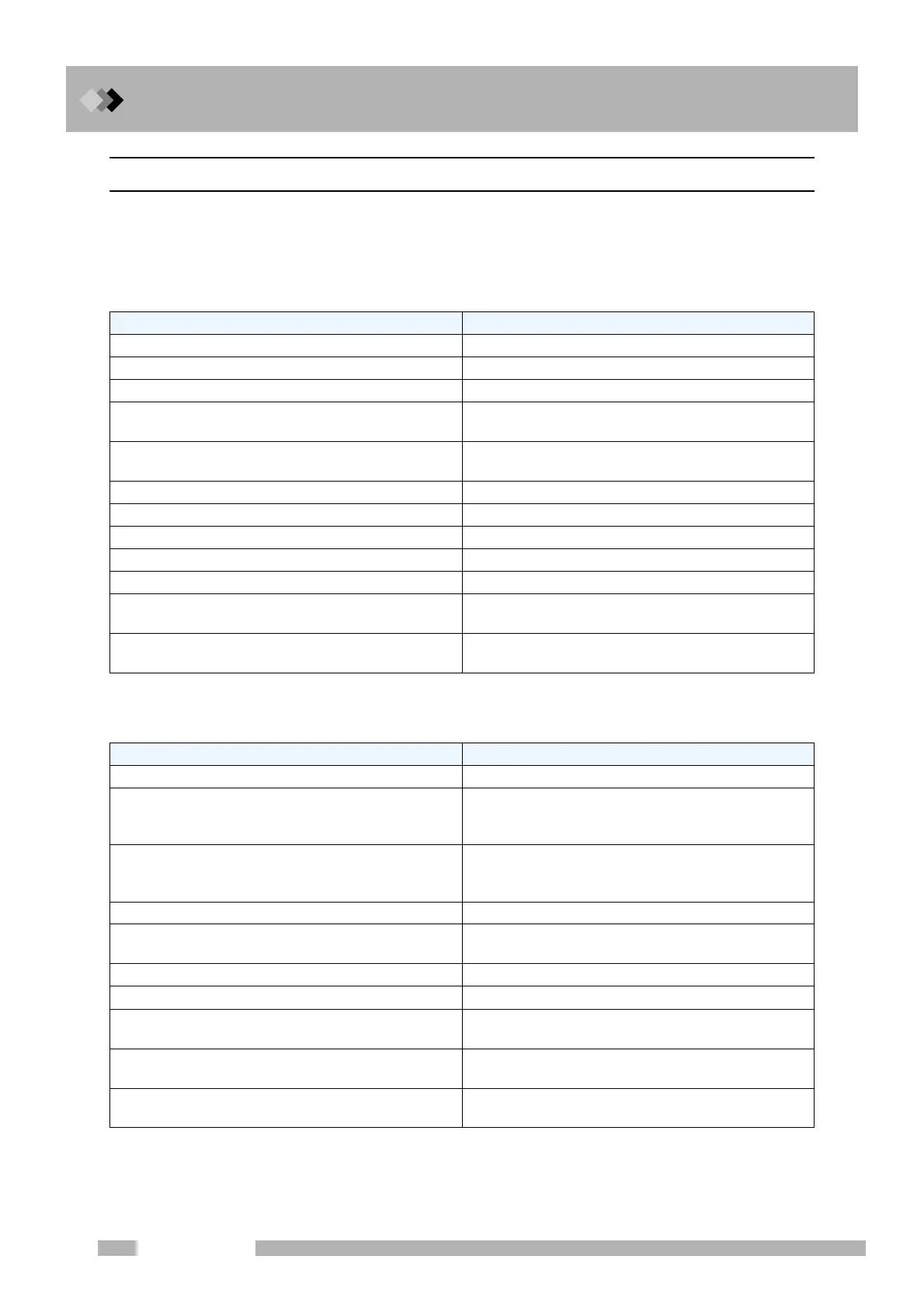

TCD detector

Possible Cause Solution

Carrier gas is not flowing. Start carrier gas flow.

Carrier gas leaks. Tighten leaking connectors.

Split ratio is too high. (for split analysis). Reduce split ratio.

Sample concentration is low. Or injection volume is

too low.

Increase sample concentration or injection volume.

Wrong column is used.

Replace existing column with one appropriate for the

compounds analyzed (more polar, less polar, etc.)

Column temperature is too low. Increase column temperature.

Signal cable of detector is connected incorrectly. Connect signal cable correctly.

Detector is set to “Off”. Set detector to “On”.

Detector parameter have been is set incorrectly. Increase range and attenuation sensitivity.

Hydrogen flame is extinguished. Check hydrogen/air flow rate, then ignite.

Zero level far below “0”.

Press “MONIT” key then press “ZERO Adj” (PF

menu) to execute zero point adjustment.

Another analytical condition, such as temperature or

column flow rate is incorrect.

Change the analytical conditions.

Possible Cause Solution

Range is not “×1”. Set range to “×1”.

Current set value is too low.

Increase current setting.

(Decrease TCD thermostatic oven temperature, and

increase maximum working current.)

Makeup gas flow rate is too high.

Set it to the proper value.

He: Approx. 7.5 mL/min

N

2: Approx. 8.0 mL/min

Split ratio is too high (for split analysis). Decrease split ratio.

Carrier gas leaks.

Check for injection port and column connection

leaks. Tighten leaking connector.

Capillary column is installed incorrectly. Install column correctly.

Column is contaminated. Condition column.

Sample concentration is low. Or injection volulme is

too low.

Increase sample concentration or injection volume.

Wrong column is used.

Replace existing column with one appropriate for the

compounds analyzed (more polar, less polar, etc.)

Another analytical condition, such as temperature or

column flow rate is incorrect.

Change the analytical conditions.

Loading...

Loading...