12 Injection Port

12.5 Split/Splitless Injection System

130

GC-2010 Plus

12.5.5 Pressure program

You can set a program to increase and decrease the column inlet pressure during analysis.

If high-boiling point contaminants are clunting shorlty after the target compounds, a pressure

program can be used so that the oven temperature does not need to be set higher than nec-

essary. This prolongs column service life.

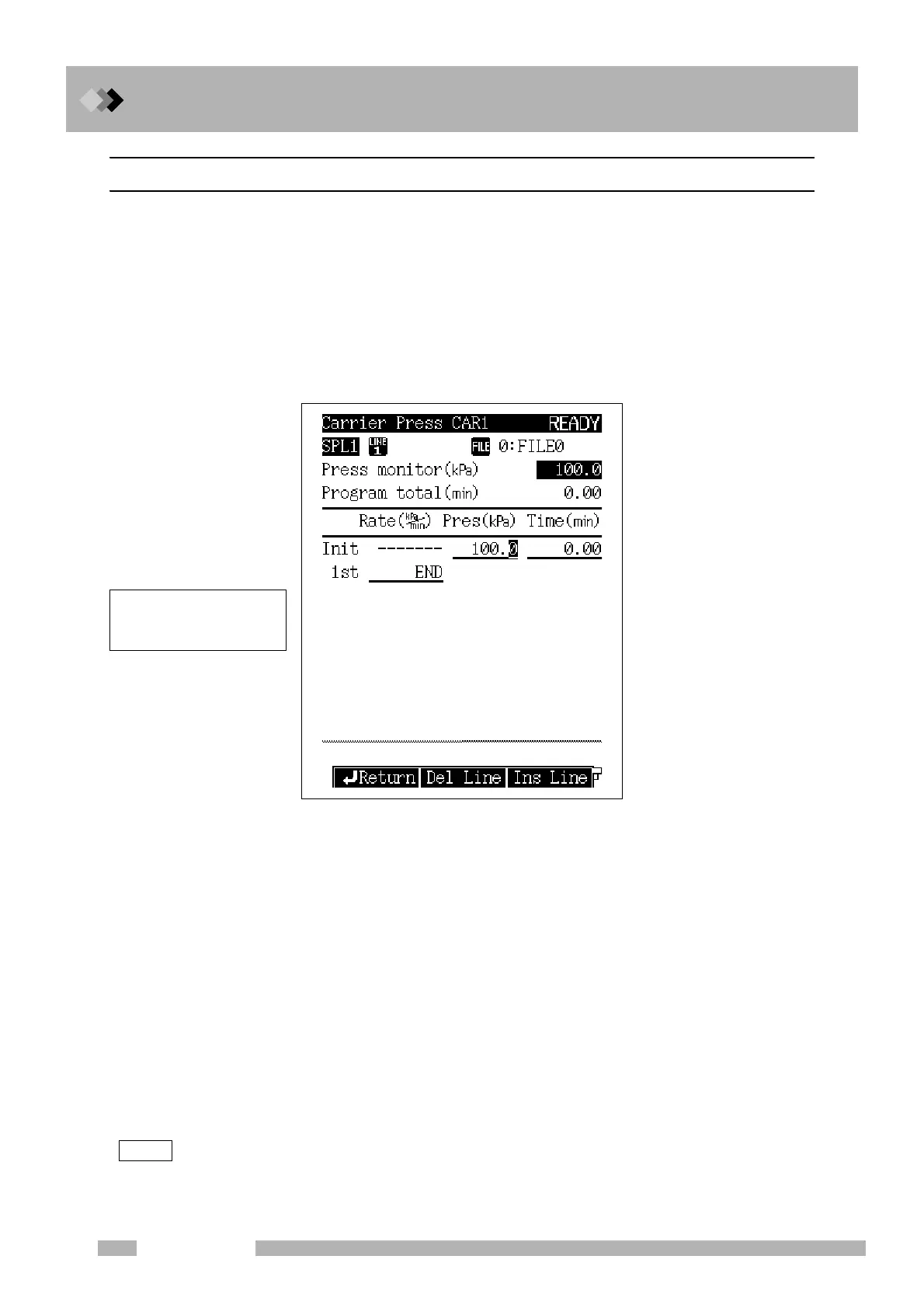

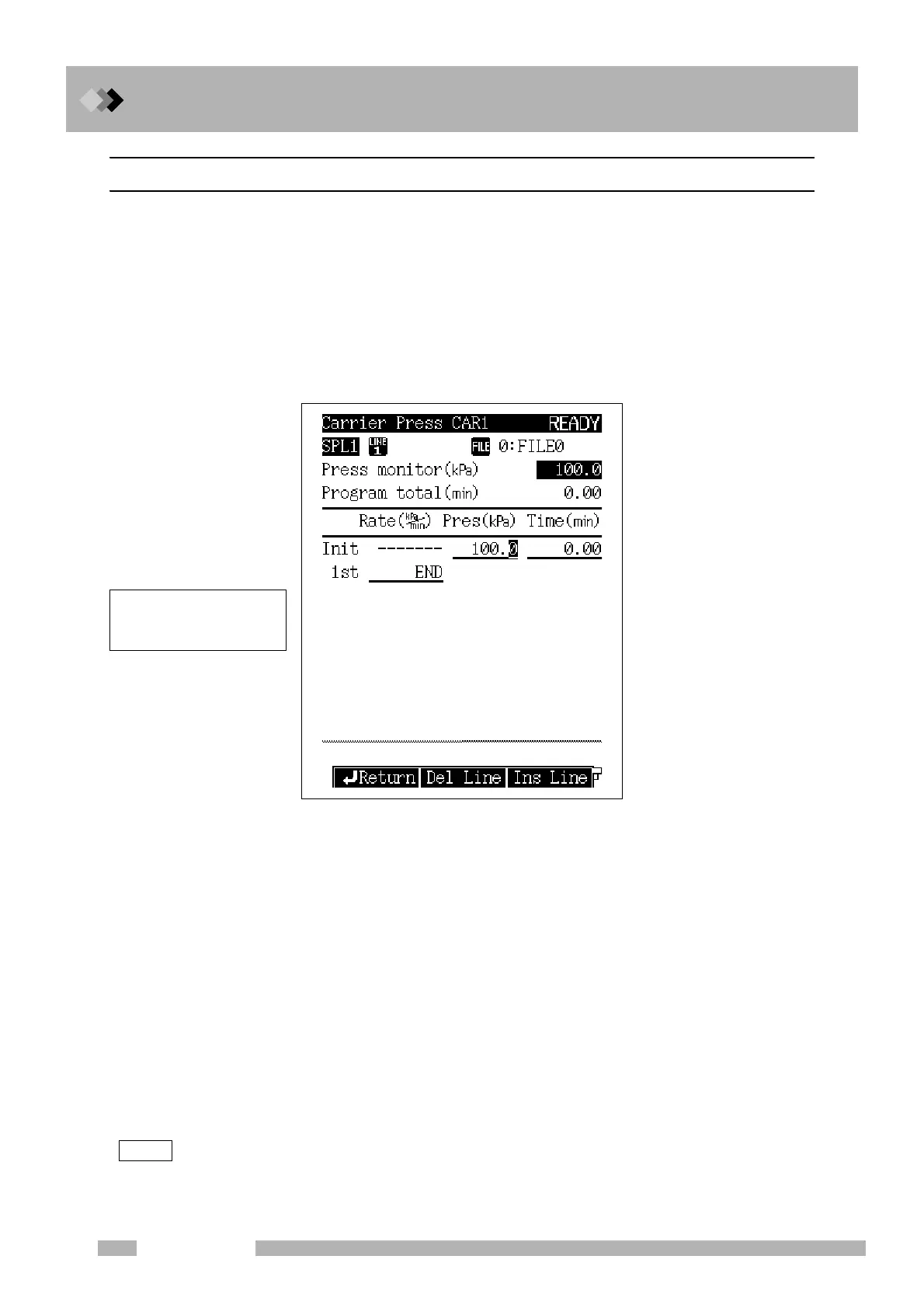

12.5.5.1 Screen description

Select [Press Prog] (PF menu) from the [FLOW] key main screen when the control

mode is set to “PRESS,” to display the carrier press screen shown in Fig. 12.5.7

appears.

12.5.5.2 Parameter list

PRESS

Range: 0.0−970.0 kPa (Refer to Fig. 3.5.1.), Default: 100 kPa

Set the initial pressure and the final pressure for each stage of the pressure program.

TIME

Range: 0.0−9999.99 min, Default: 1.00 min

Set the hold time for the initial pressure and the final pressure for each stage of the

pressure program.

RATE

Range: END/-400.00−400.00 kPa/min, Default: END

Set the pressure program rate.

If you set the rate to “0”, “END” appears and the program finishes at the previous ramp.

If you move the cursor to “END” and set any numeric value other than “0”, the pressure

and the time for that ramp can be enterd.

NOTE The pressure increase/decrease program rate control range may be limited depending on the total flow

rate setup value, the column in use and the purge flow rate.

Fig. 12.5.7 Pressure program setup screen

Up to 7 ramps of pressure

increase or decrease can be

set.

Loading...

Loading...