20.1

20.

327

GC-2010 Plus

20 Appendix

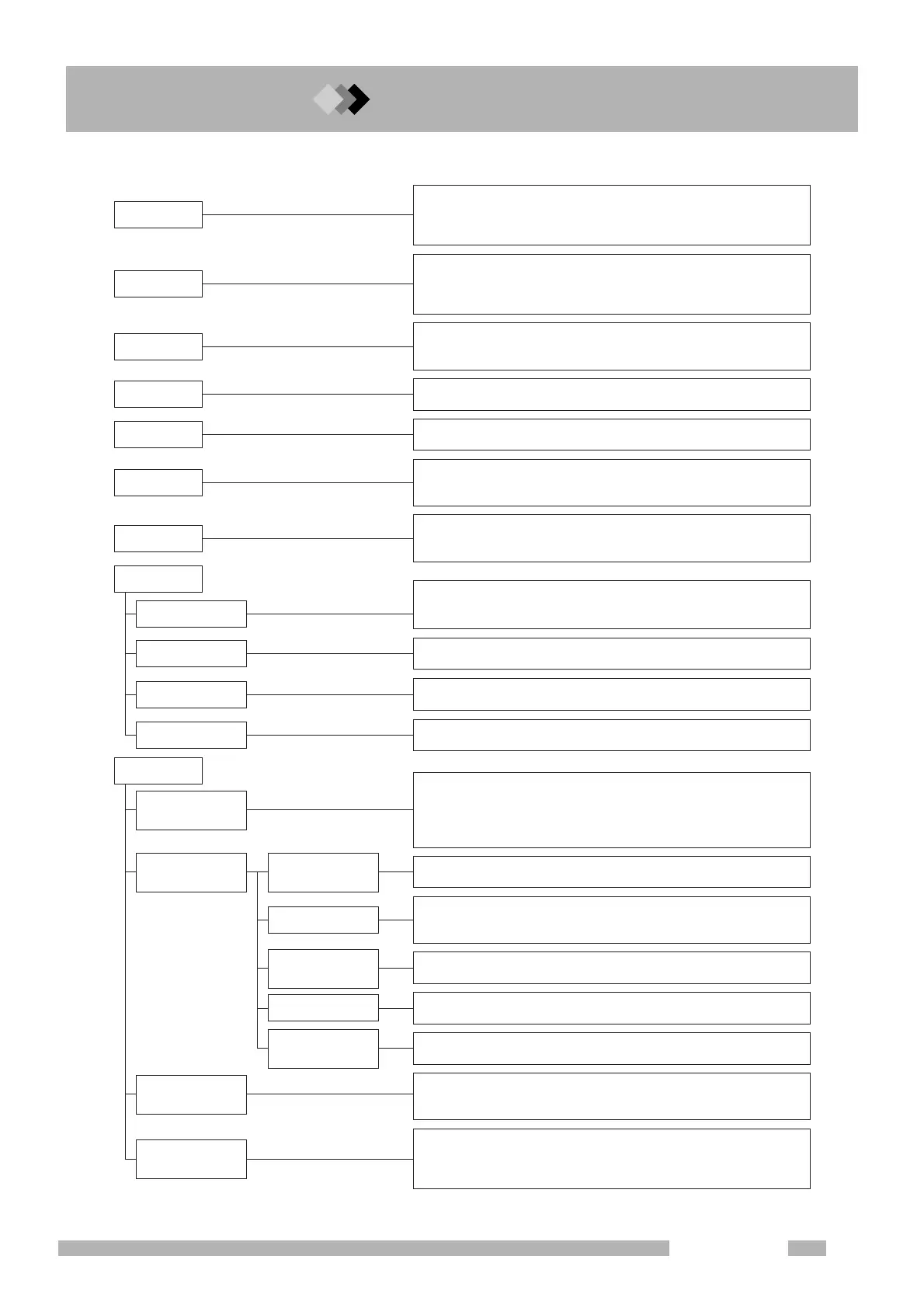

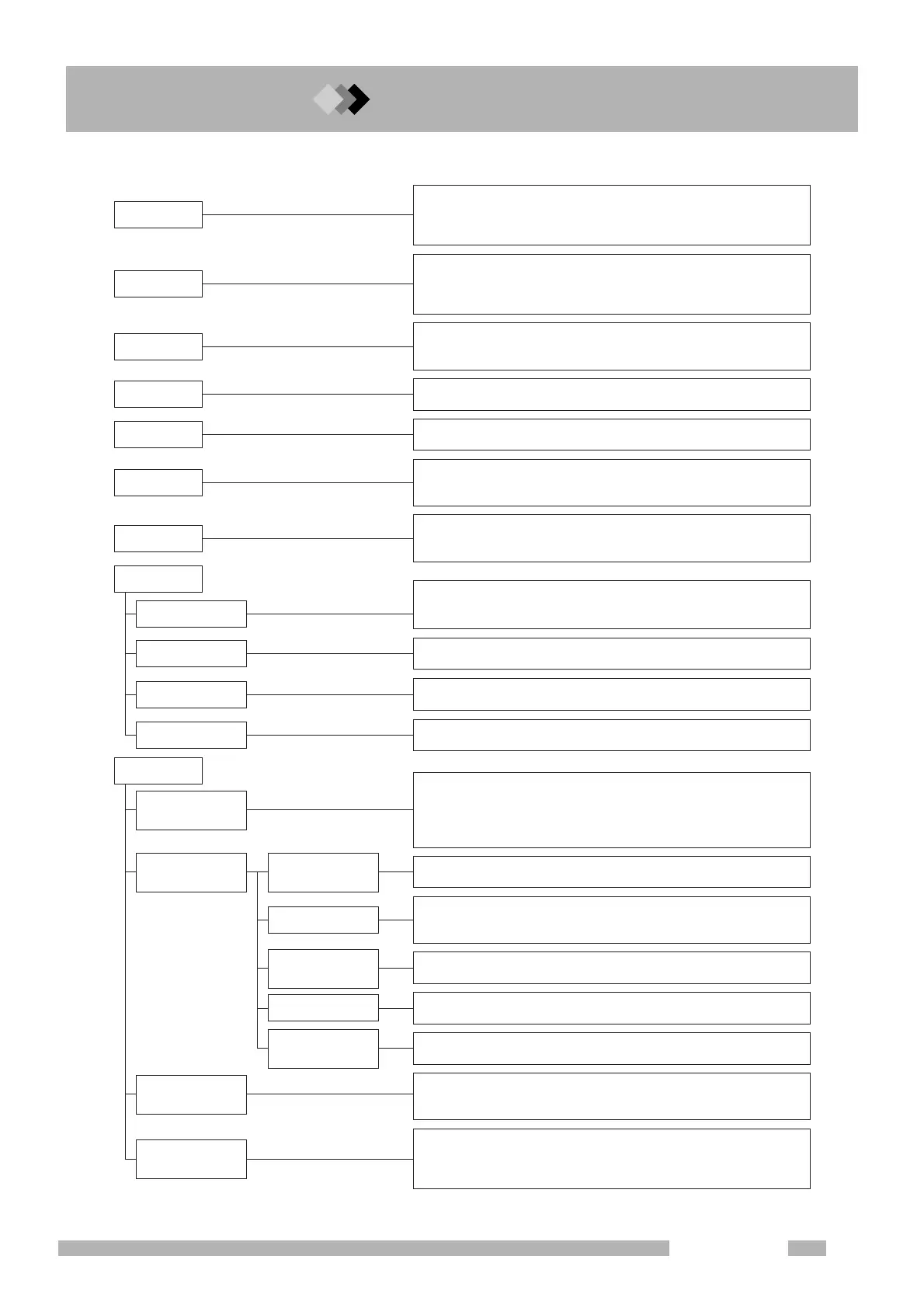

20.1Key Function List

The parameter related to start and stop of the GC can be set. And on

the sub screen, the file management, the clean up and the

maintenance of injection port can be set.

The Auto Injector AOC-20i and the Auto Sampler AOC-20s used to

automatically inject liquid sample to the gas chromatograph can be set.

The parameters which are frequently set can be set. And on the

screen of [LineConfg], the combination of injection ports,

detectors,etc. can be changed.

The status of the injection port, the column, the detector configured

and the chromatogram etc. in each line can be monitored.

The parameters of the AFC which controls the pressure and the flow

rate of the carrier gas can be set.

The detector temperature, the deterctor gas flow rate, the detector

signal output,etc. can be set.

The oven temperature or the oven temperature program can be set.

The injection port temperature can be set.

The CRG (option) can be set.

SYSTEM

SET

MONIT

COL

INJ

FLOW

DET

AOC parameters

OPTION

The AUX APC (option) can be set.

AUX APC

The AUX Temp (option) can be set.

AUX Temp

CRG

The total time that the CRG is "On" can be confirmed. If the

consumption counter is larger than the time of setting to warm, the

warning message is displayed.

Diagnose each part of the gas chromatograph to check for

abnormality.

By executing standard diagnosis periodically, the system can be

managed and the failures can be prevented.

Display the log on whether analysis was executed to the end and

whether the control was not deviated from the target value.

The replacement timing of the septum or the glass insert can be

displayed as an warning message.

Display the power On/Off log and the system On/Off log.

Display the key operation log and the parameter change log.

Display the log of displayed error messages.

Display the diagnosis log.

1. Standard

Diagnosis

DIAG

2. Log Reading

Menu

1. GC operation

Log

2. Analysis Log

3. Parameter

Log

4. Error Log

5. Diagnostic

Log

3. Analysis

Countur

4. Coolant

Consumption

Loading...

Loading...