3 AFC, APC

3.4 AFC and APC control

38

GC-2010 Plus

3.4.3 Split mode: “SPLITLESS” (AFC)

The control method changes only during the sampling time. During sampling time, the AFC

controls the TFC (Total Flow Controller) so that the output from the column inlet pressure

sensor becomes constant, and then controls the column inlet pressure.

After the sampling time, the AFC controls the total flow rate to keep it at a constant value

using the TFC (Total Flow Controller) inside the AFC. As in split mode, the ESC (Electronic

Split Controller) is controlled to maintain the column inlet pressure constant.

Figure 3.4.2 shows the control status during the sampling time with a split ratio of 1:40, a

velocity of 30 cm/sec, a purge flow rate of 3 ml/min, and a column oven temperature of 50 °C.

The column inlet pressure is calculated based on the linear velocity, the oven temperature,

the column inner diameter, the column length and the column film thickness, and is

automatically set to 49.6 kPa. In the same way, the column flow rate is automatically set to

1.67 ml/min.

When the sampling time expires, control is identical to the split mode, shown in Fig. 3.4.1

When the Control mode is set to “PRESS”, the column inlet pressure is controlled to remain

at 49.6 kPa regardress of the column oven temperature.

When the Control mode is set to “VELOCITY”, the column inlet pressure is set to a value

which keeps the linear velocity constant despite changes in the column oven temperature.

Even if the column oven temperature changes, as in programmed temperature analysis, the

linear velocity is always kept constant. Generally, when the column oven temperature

increases, the viscosity of the carrier gas also increases, and does not flow as easily.

Regardless of the Control mode, the ESC controls the column inlet pressure and the TFC

controls the total flow rate as shown in Fig. 3.4.1. (after the sampling time).

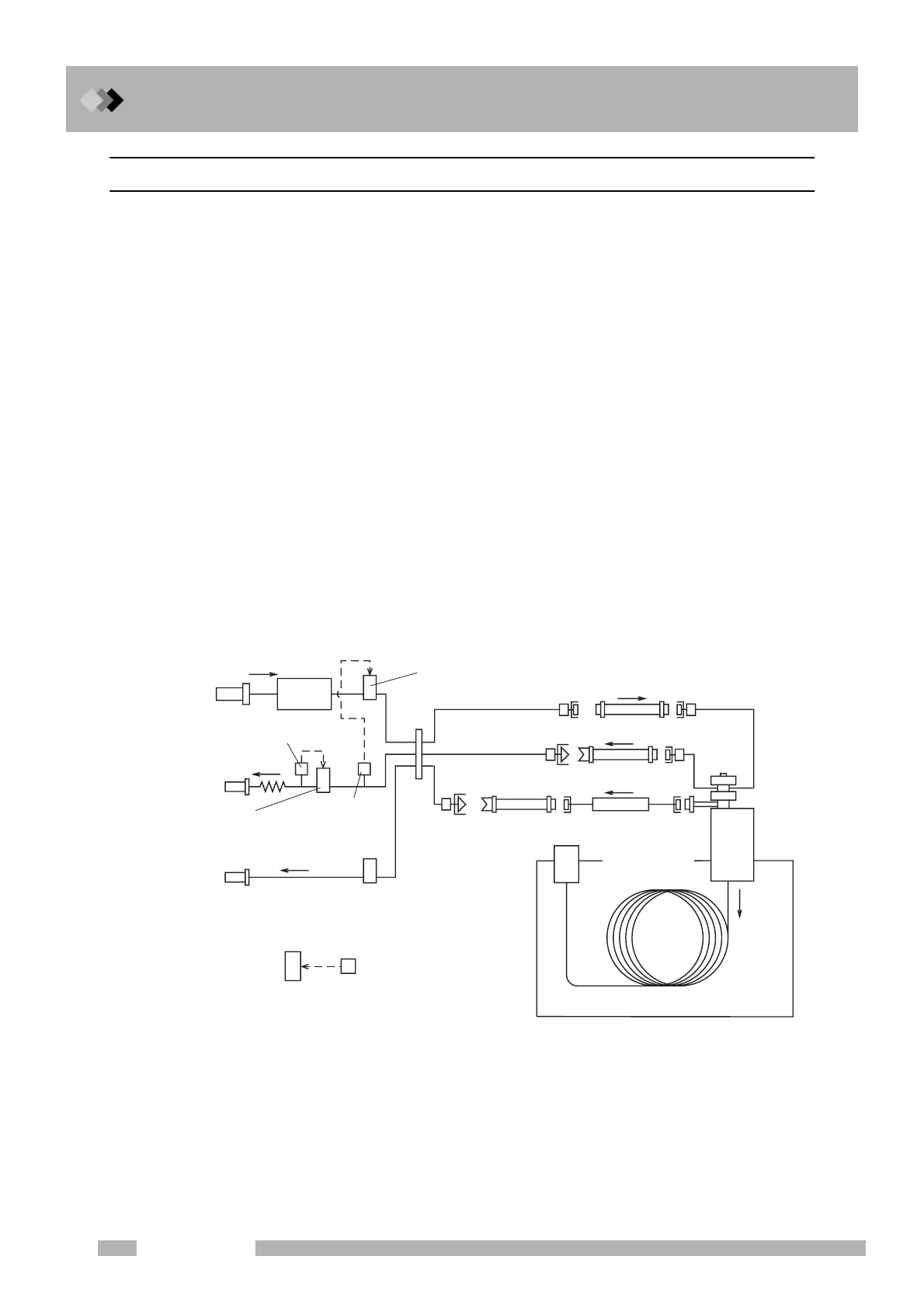

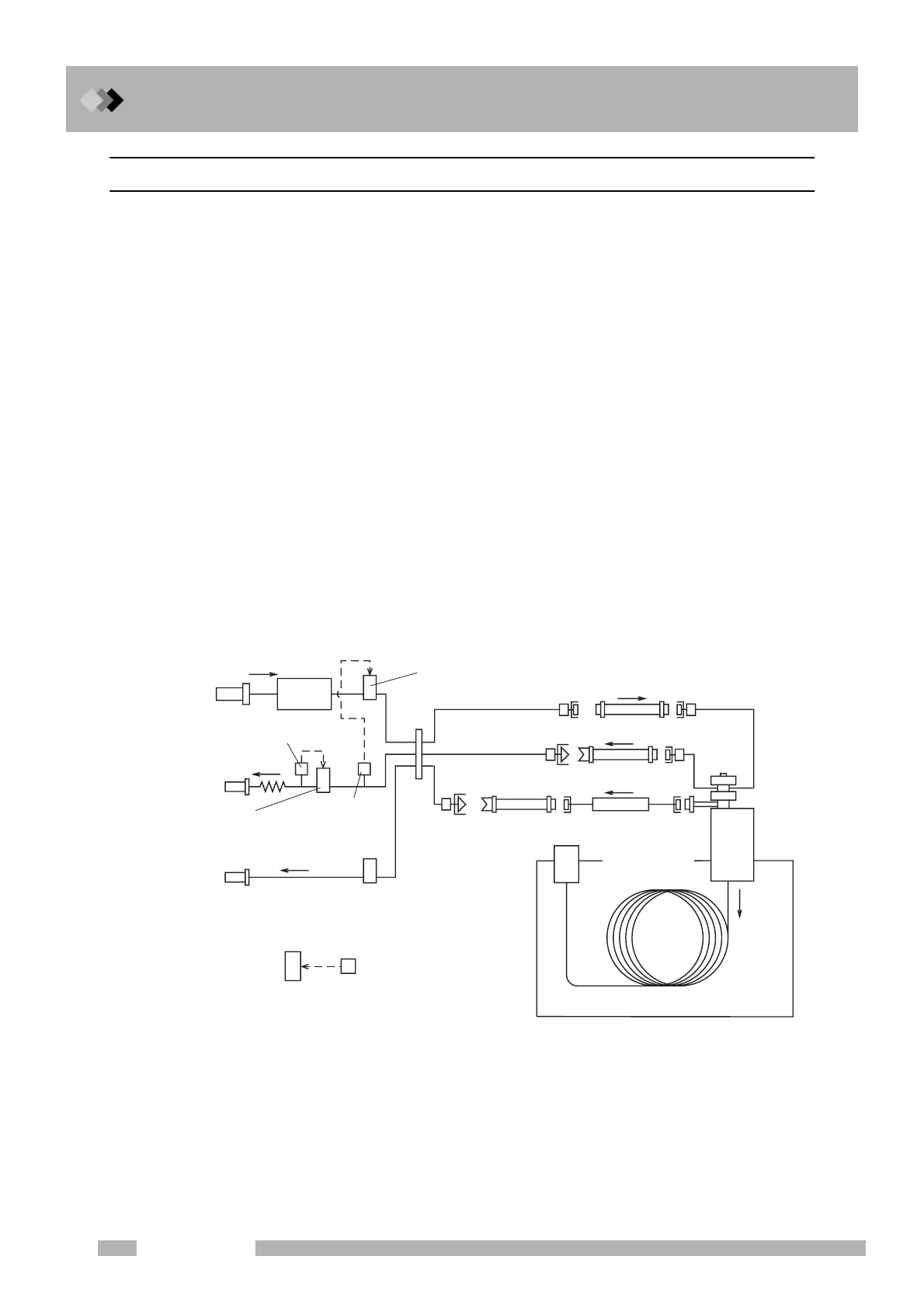

Fig. 3.4.2 Splitless control (during sampling time)

CARRIER IN

(GC rear)

PURGE VENT

SPLIT VENT

Column oven

(50 )

Flow rate

sensor

TFC

(Total Flow Controller)

Pressure sensor

Pressure sensor

SPC

(Septum Purge Controller)

ESC

(Electronic Split Controller):

Completely closed

Valve “b” Sensor “a”

Valve “b” is controlled so that the value of

sensor “a” remains constant.

Detector

99.1 kPa

4.67 ml/min

3 ml/min

0 ml/min

4.67 ml/min

C

P

C

P

S

3 ml/min

0 ml/min

1.67

ml/min

Column inner diameter : 0.32 mm

Column length : 25.0 m

Film thickness : 0.50 µm

Carrier gas : He

Injection

port

Loading...

Loading...