19 Troubleshooting

19.1 Troubleshooting

310

GC-2010 Plus

19.1.1 Gas and pressure settings

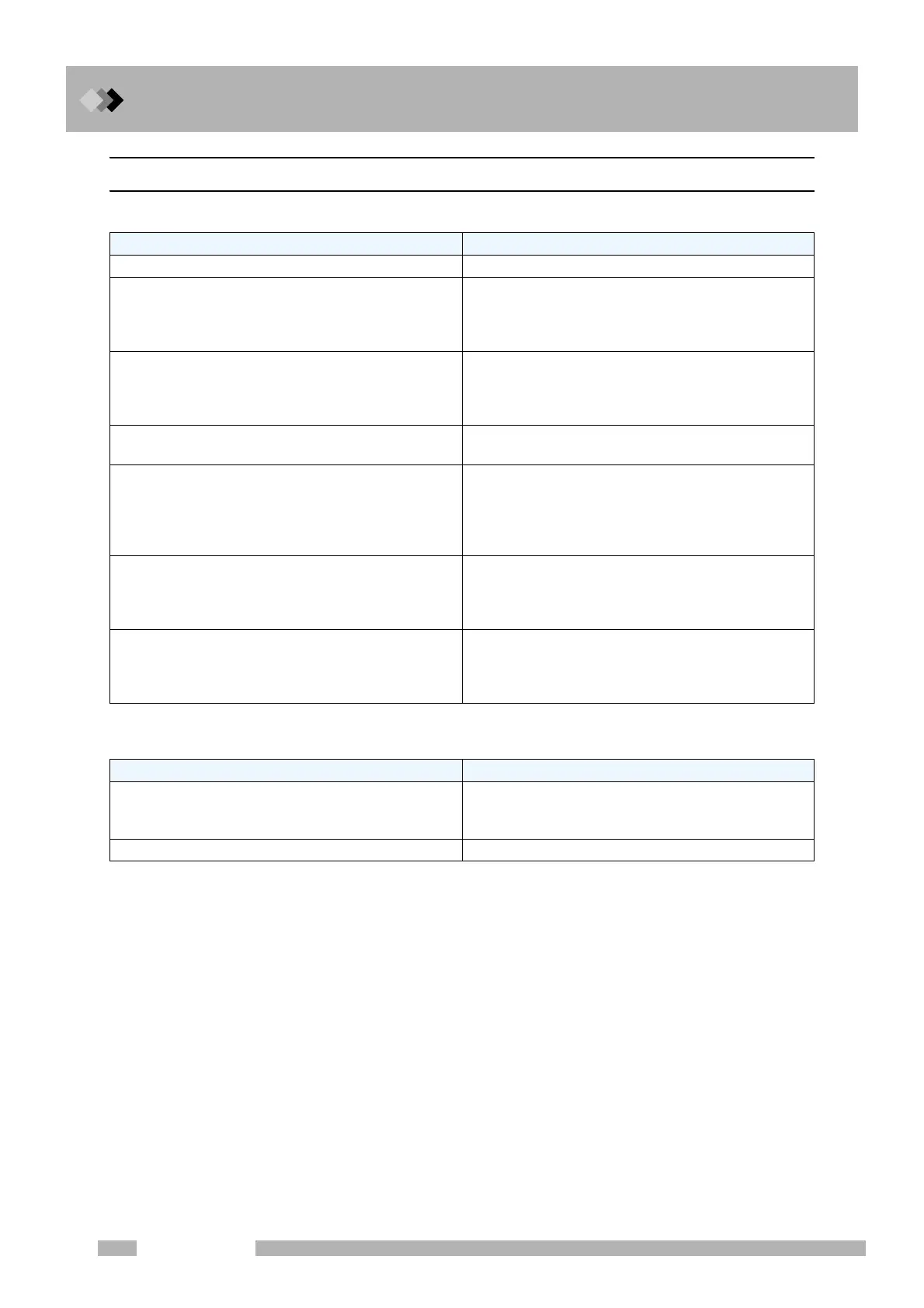

19.1.1.1 When the pressure/flow rate cannot be set or does not attain the set value

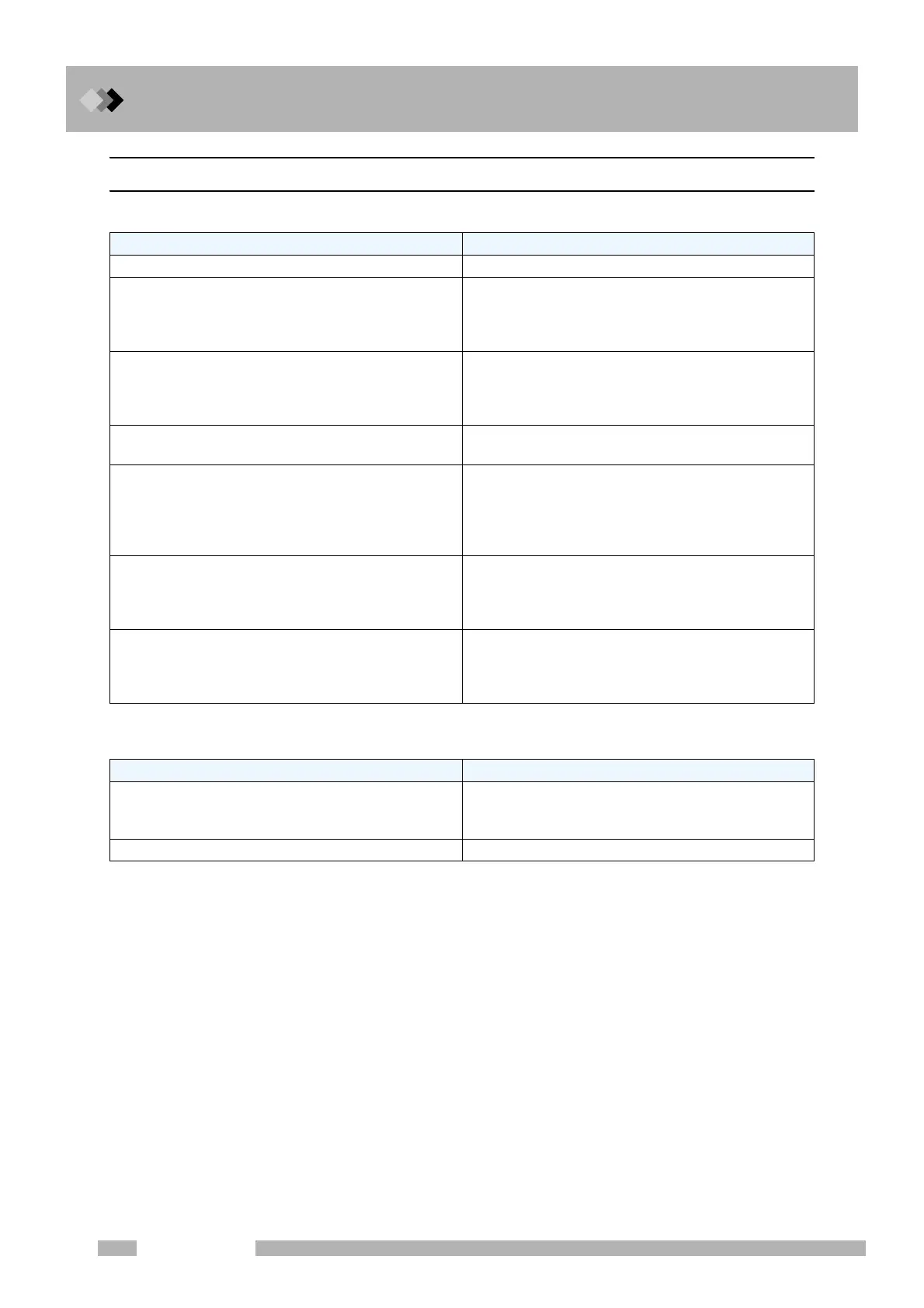

19.1.1.2 Continual gas leaks

If tubing or connections are damaged, replace them.

If the problem can not be solved, contact your shimadzu representative.

Possible Cause Solution

No gas is supplied. Open gas cylinder main valve to supply gas.

Supply pressure is low.

Set carrier gas supply pressure to 300 to 980 kPa.

Hydrogen: 300 to 500 kPa

Air: 300 to 500 kPa

Makeup gas: 300 to 980 kPa

Gas leaks

Check for gas leaks, and tighten leaking connections.

Replace gasket or septum.

(Refer to “2.6 Gas supply plumbing” in the Instruction

Manual.)

AFC/APC: Incorrect valve set.

Set value is outside controllable range.

Set pressure to proper value.

(Refer to “3 AFC, APC” in the Instruction Manual.)

Carrier gas type, column length, inner diameter and

film thickness are incorrect.

Set carrier gas type, column length, inner diameter

and film thickness correctly.

(Refer to “12.5.2” and “12.6.2 Setting the flow rate”

and “12.5.3 Setting column parameters” in the

Instruction Manual.)

Total flow rate is set too low, and pressure cannot

increase.

(In this case, measured flow rate of split vent is

extremely low.)

Increase the total flow rate.

(Refer to “3 AFC, APC” in the Instruction Manual.)

Split vent trap is clogged.

(Even if total flow rate is set high, the measured flow

rate from the split vent is low and the pressure is

high.)

Replace trap.

(Refer to “18.8 Inspection and Maintenance: Flow

Controller” )

Possible Cause Solution

Part is incorrectly installed.

Install part correctly.

(Refer to “2.6 Gas supply plumbing” in the Instruction

Manual.)

Graphite ferrule or other seal is damaged. Replace damaged gasket part with a new one.

Loading...

Loading...