Parameters

List of Parameters

1-254

© Siemens AG 2007 All Rights Reserved

SINAMICS G120 Control Units CU240S, Edition 05/2007

Description: This parameter can be used to optimise the positioning ramp down.

Offset errors due to mechanical errors or other reasons can so be corrected. The value is in measures of P2488.

Negative value entered when final position is before required end point.

Positive value entered when final postioin is after the required end point.

Description: Sets the required distance or number of revolutions (see P2484).

Description: This parameter displays tracking values of the positioning ramp down functionality.

Index: [0] = Remaining number of shaft rotations since trigger.

[1] = Accumulated shaft rotations during the positioning ramp down.

[2] = Accumulated encoder increments during the positioning ramp down

Note: Index [0]:

The displayed value is in measures of P2488. Due to the open loop control mode of the positioning ramp down, the

value may show a residual difference between calculated and actually performed motor rotations. P2487 can be

used for trimming.

Index [1] reserved:

Index [2] reserved:

p2487[0...2] Positional error trim value / Positional trim / Positional error

Access level: 3 P-Group: Closed-loop control Data type: Floating Point

Quick comm. NO Active: NO Data set: DDS

Can be changed: U, T

Min Max Factory setting

-99.00 200.00 0.00

p2488[0...2] Distance / No. of revolutions / Distance / No. rev

Access level: 3 P-Group: Closed-loop control Data type: Floating Point

Quick comm. NO Active: NO Data set: DDS

Can be changed: U, T

Min Max Factory setting

0.01 99999999.99 1.00

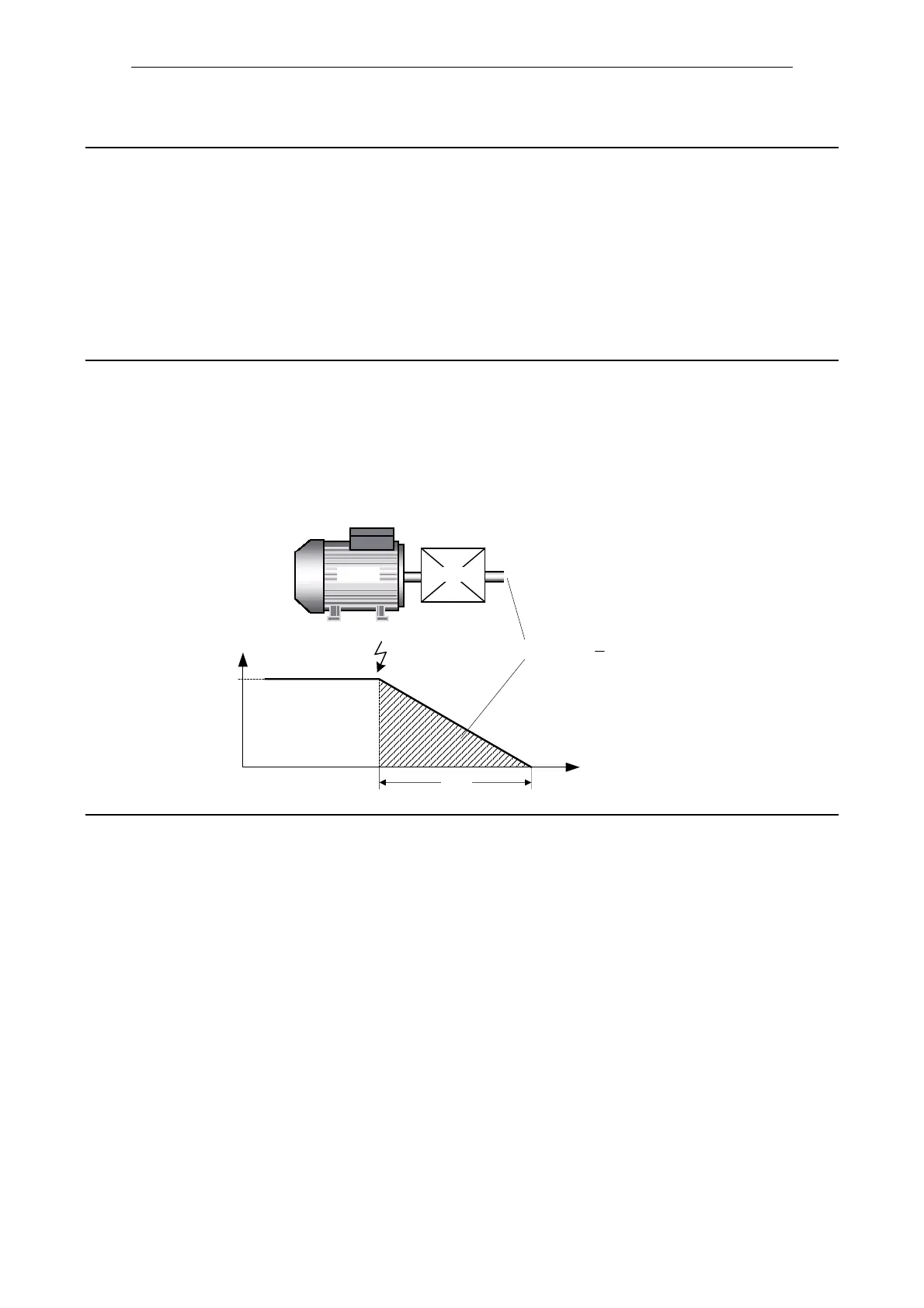

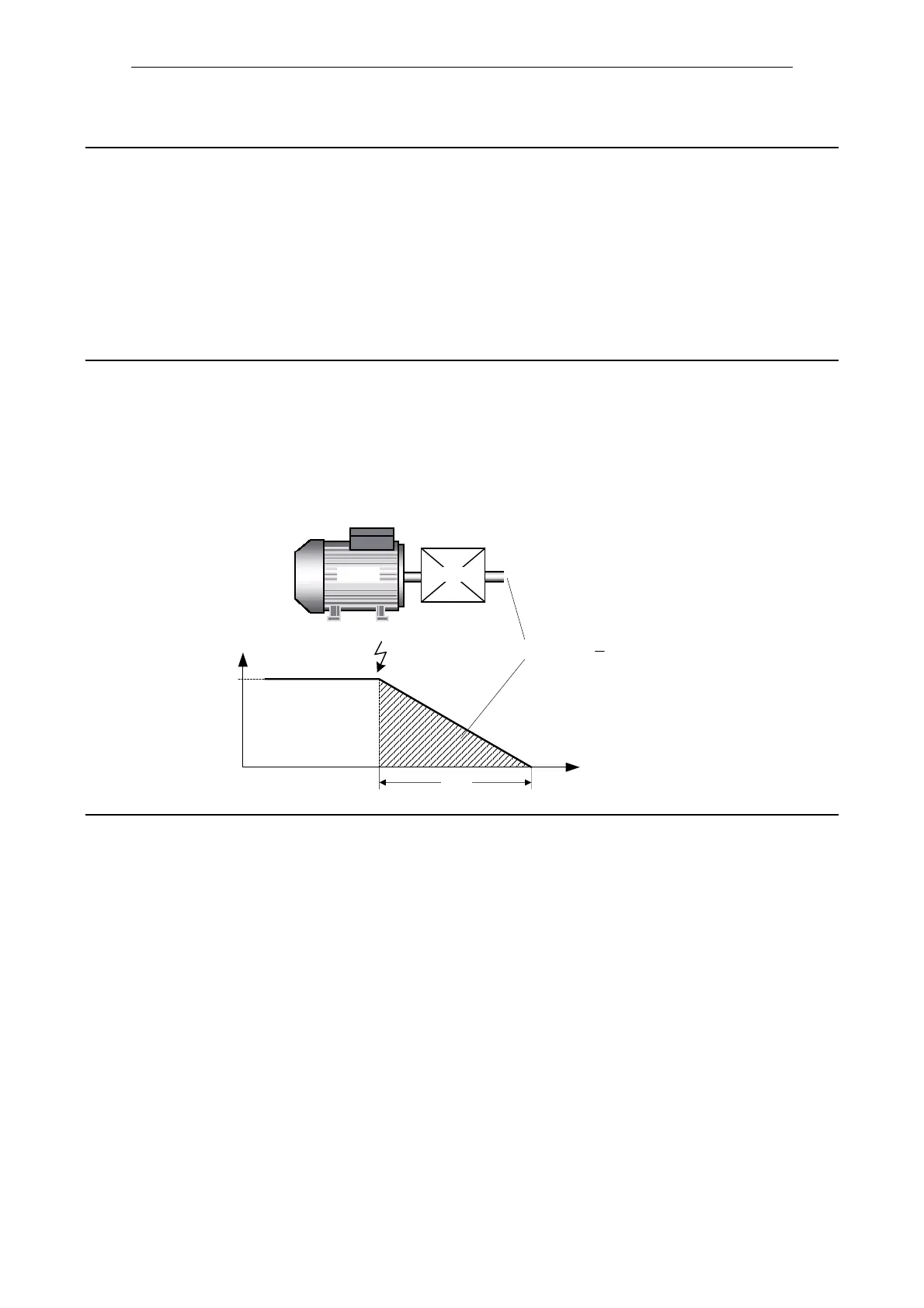

Motor Gear

f

⋅==

2

1

P2488 s

t

OFF1

f

OFF1

.

t

P2488

.

t

P2488

f

OFF1

r2489[0...2] CO: Tracking parameter / Track / Tracking parameter

Access level: 3 P-Group: Closed-loop control Data type: Floating Point

Unit: - Data set: -

Loading...

Loading...