1-10 Service Manual

4023-001

Paper Exit Section

After the paper passes the fusing section, the paper exit roller ejects

the paper out the top of the printer. The paper exit sensor (PC3)

senses the ejection of the paper.

Optional manual and duplex unit installed:

The duplex unit switchback motor pulls the trailing edge of the

printed paper inside the duplex unit. The duplex unit transport motor

then feeds the paper to the manual unit where the paper remains

until the second print command.

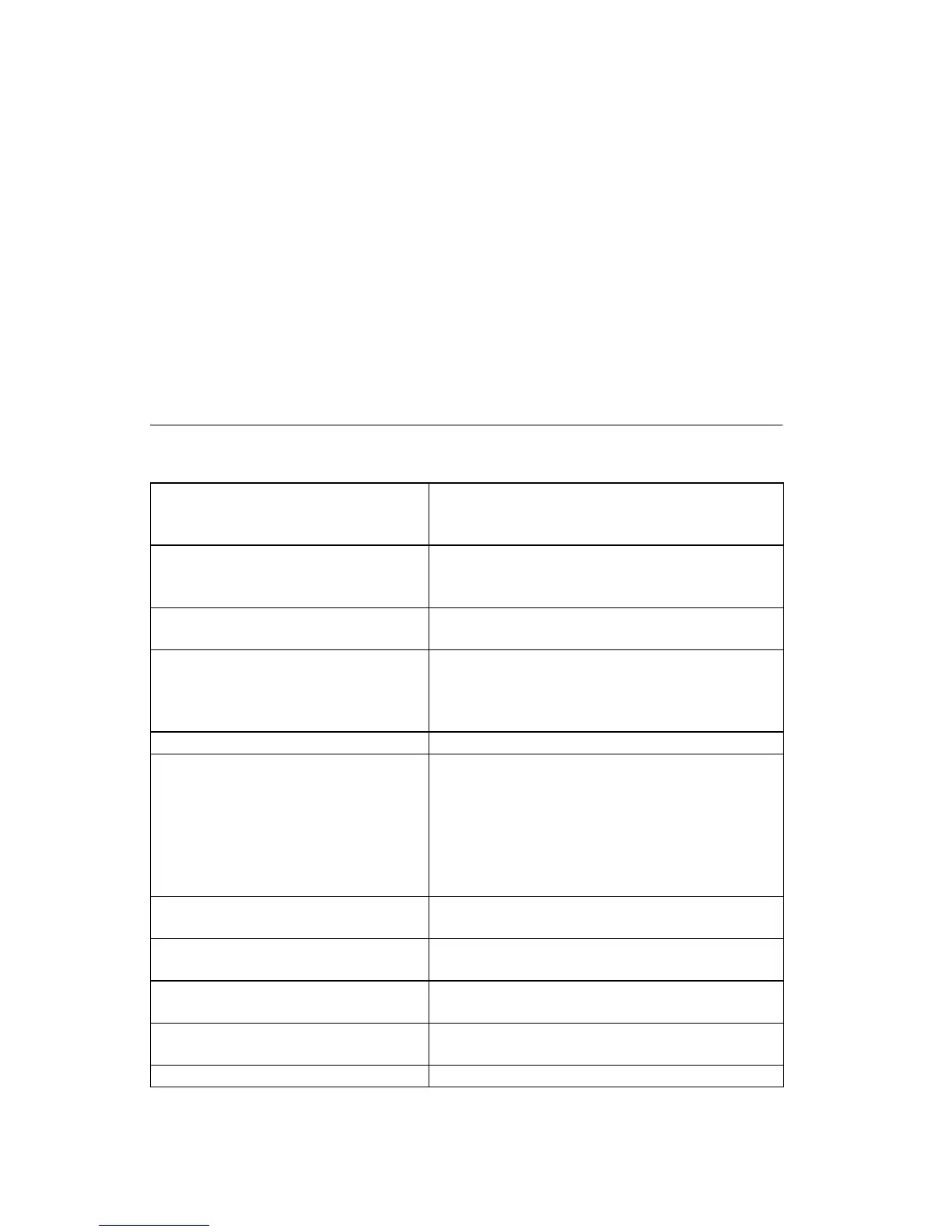

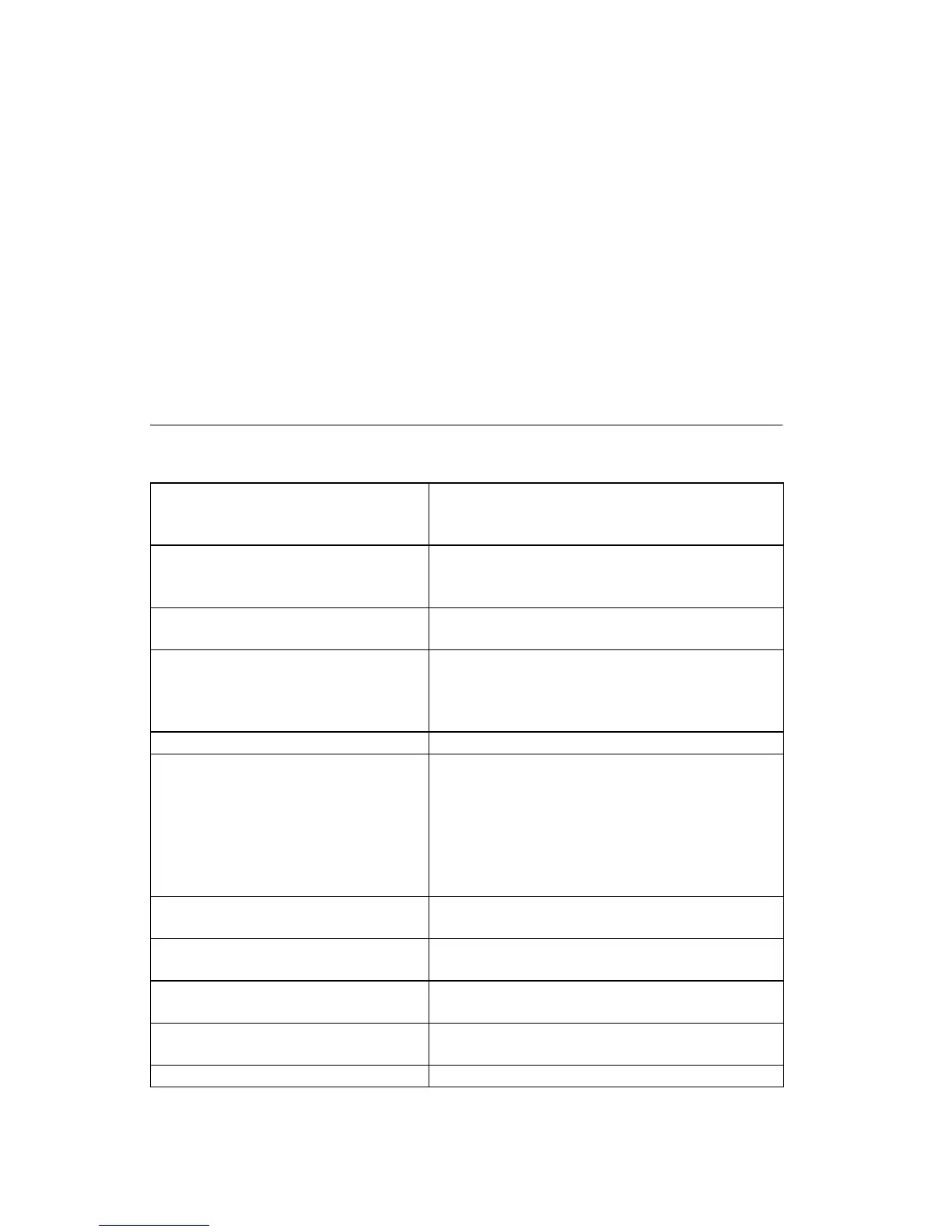

General Flow for Printing Process

Print command

Polygon Motor ON

The motor in the printhead unit starts

turning.

Cleaning The transfer roller becomes negatively

charged to prevent the negatively-charged

toner from sticking to the PC Drum.

Starting processing The I/C (imaging cartridge) drive motor (M1)

starts turning.

Paper take-up The transport motor (M2) starts turning.

The paper take-up solenoid turns on to feed

paper.

Laser emission A laser beam is emitted at constant power.

Scanning the image data

Paper feeding

A laser beam scans the surface of the PC

drum to produce a latent electrostatic image.

The sychronizing roller sensor (PC2) detects

the presence of paper. The sychronizing

clutch then turns on which turns on the

sychronizing roller for feeding paper.

Developing the image data Toner is applied to the PC drum to produce a

visible toner image.

Transfer the image data The toner image on the surface of the PC

drum is transferred onto the paper.

Fusing the toner The toner is permanently fixed onto the

paper.

Cleaning Excess toner and electric potential on the

PC drum are eliminated.

Paper ejection The paper ejects.

Loading...

Loading...