General Information 1-71

4023-001

Upper Exit Motor Control

Changing the driving action varies the upper exit motor (M2) speed.

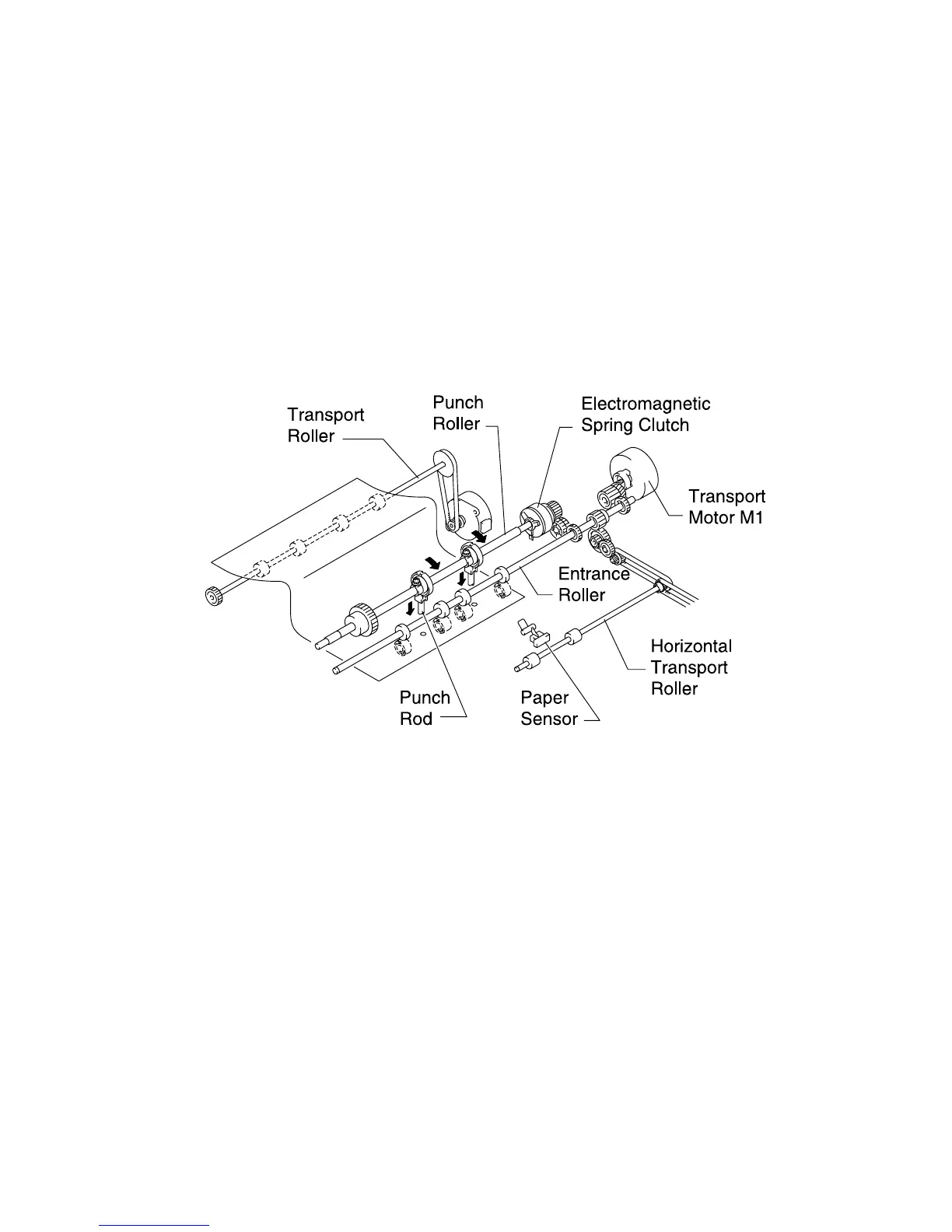

Punch Mechanism

The print traveling through the finisher briefly stops, allowing the

punch rods to punch the paper.

The transport motor and the electromagnetic spring clutch fitted to

the punch roller energize and de-energize, moving the punch rods

up and down to punch holes in the print.

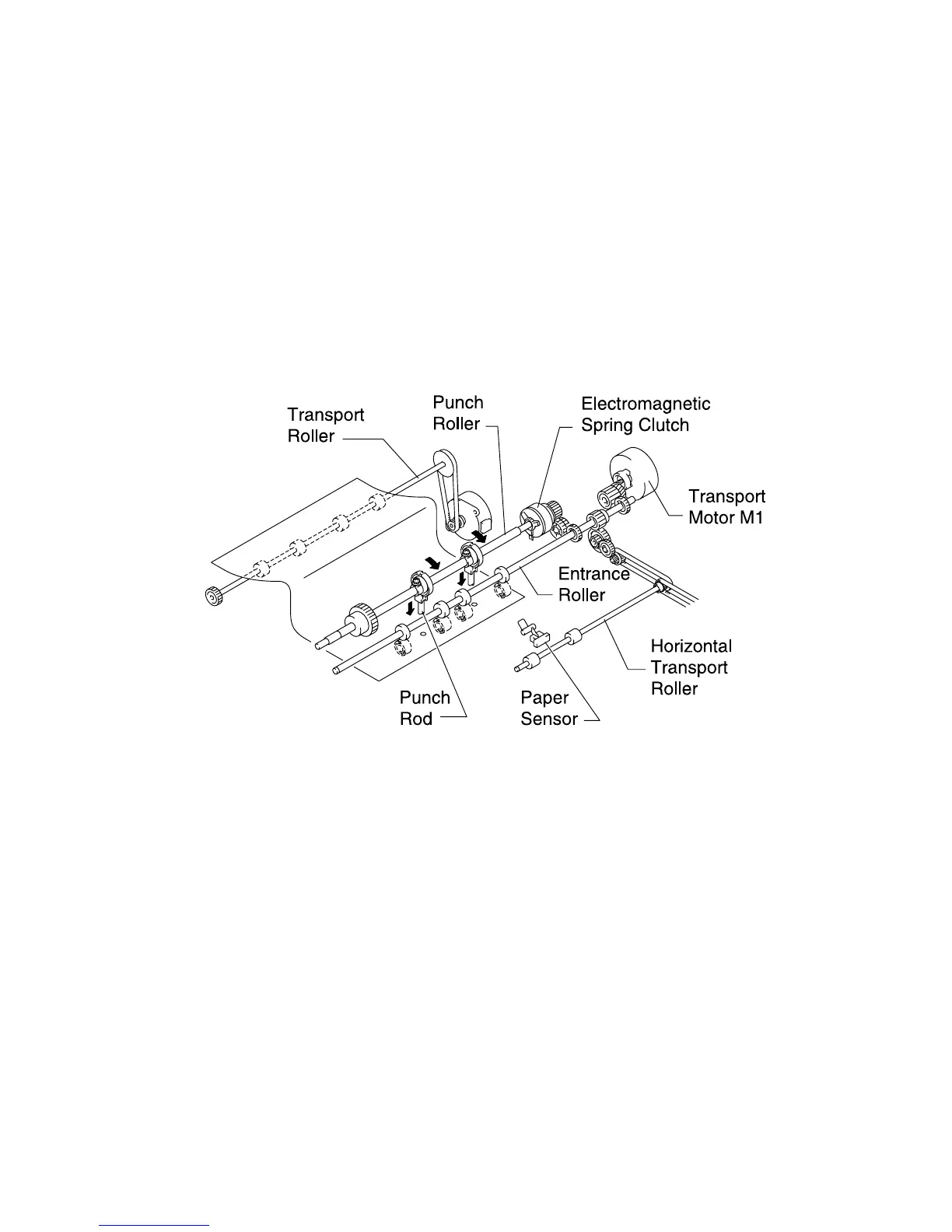

Punch Operation

The print transports from the printer into the horizontal transport unit.

M1 energizes to turn the horizontal transport rollers and entrance

roller. At the same time, upper exit motor energizes to turn the

transport roller. The trailing edge of the print moves past the paper

sensor of the horizontal transport unit. After a given period of time,

the upper exit motor deenergizes to stop the transport roller. The

transport motor remains energized, forming a loop in the print before

the transport roller. The electromagnetic spring clutch energizes

causing the Punch Roller and eccentric cams to turn. The eccentric

cams cause the punch rods to move up and down, punching holes in

the print. The upper exit motor energizes again to feed the print into

a tray or bin.

Loading...

Loading...