1-14 Service Manual

4023-001

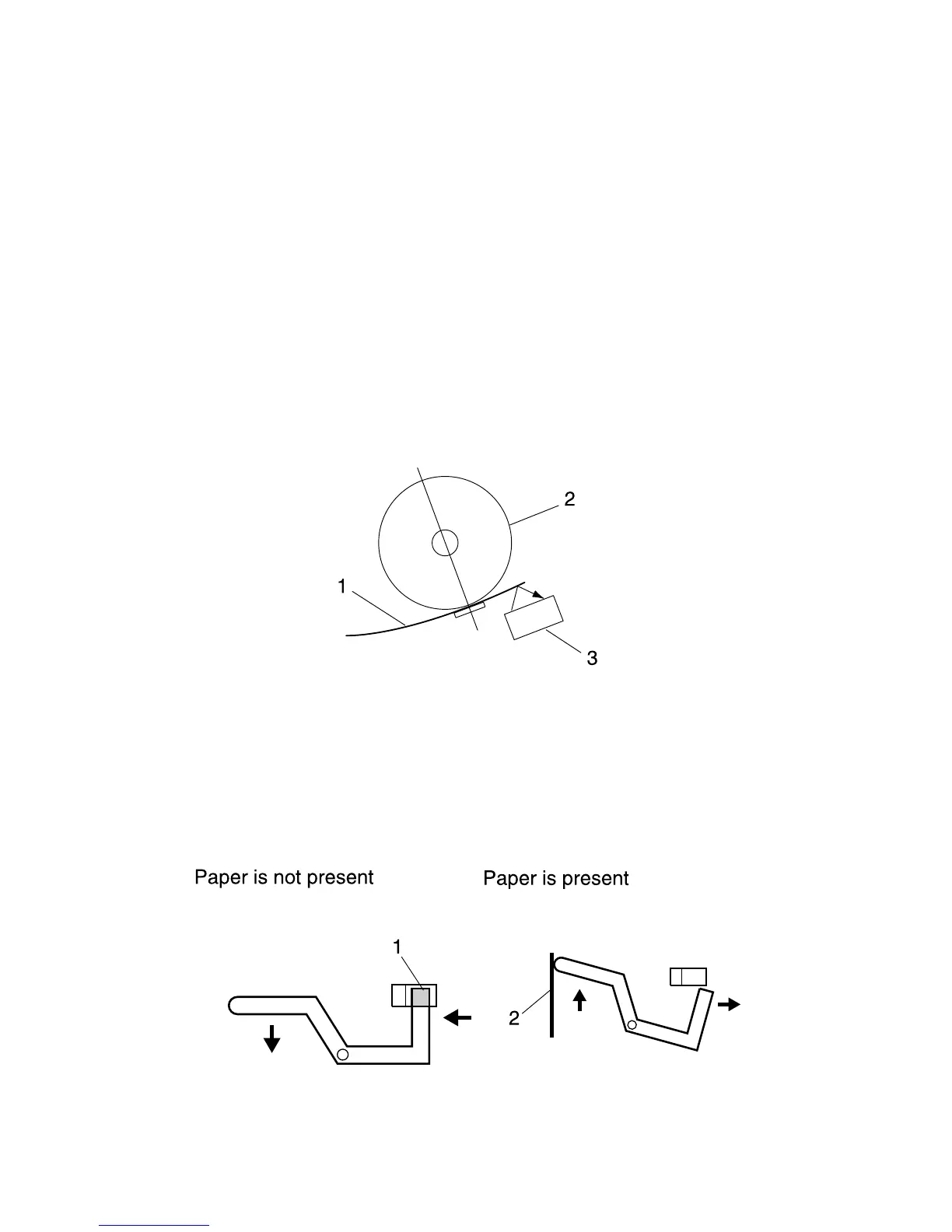

1st Cassette Tray 1 Double Feed Sensor

The double feed sensor (located on the double feed detecting

sensor board (PWB-H)) detects the possibility of double feed. This

sensor uses a photo reflector.

The double feed sensor detects whether the leading edge of paper

to be taken up next runs 10 mm or more from the paper nip point. If

paper runs 10 mm or more, double feeding may occur if the paper is

taken up in the normal printing interval. To avoid this, the printer

prolongs the printing intervals as long as the double feed sensor

detects a double feed status. This results in the reduction of the

number of sheets fed per minute.

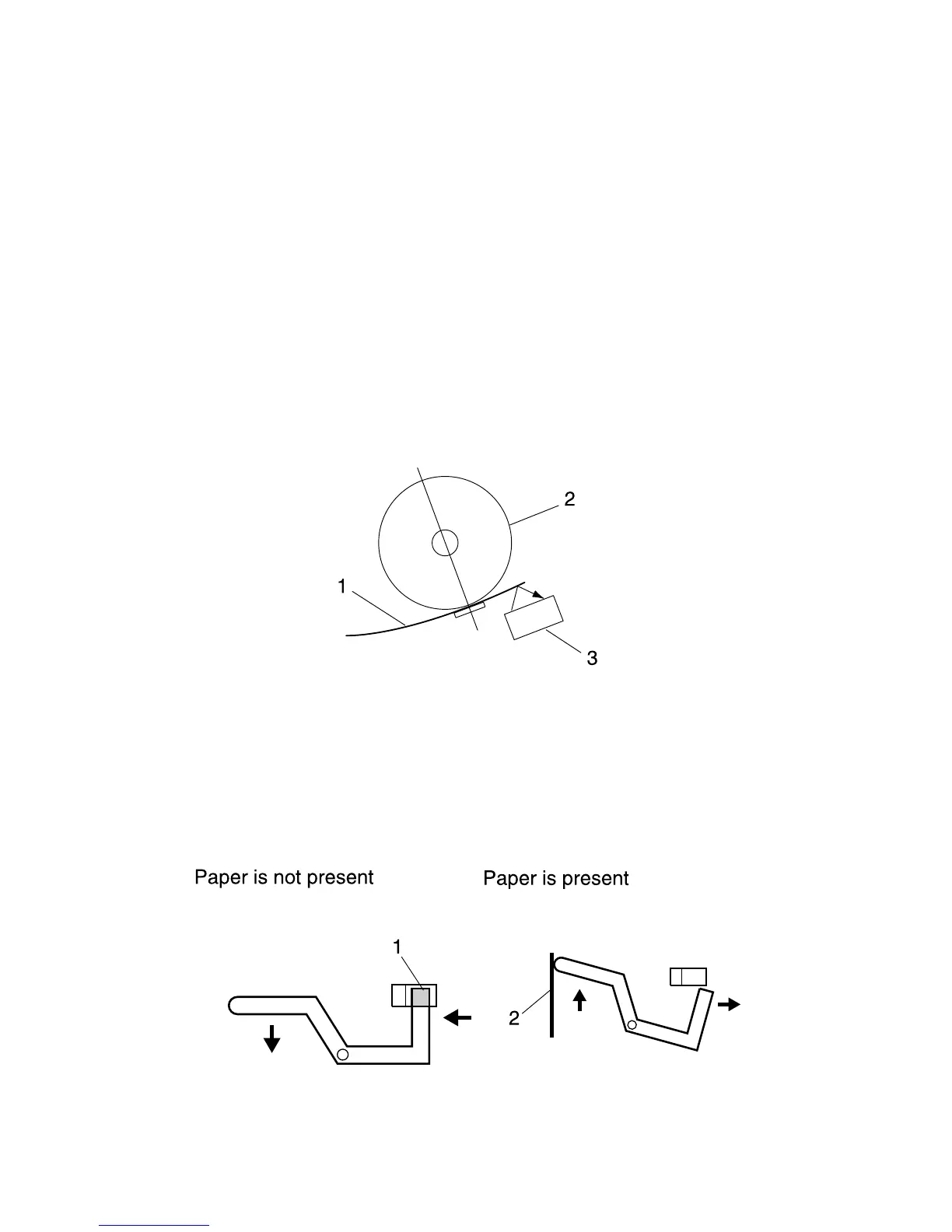

1st Cassette Tray 1 Synchronizing Roller Sensor (PC2)

This sensor detects that the paper is fed inside the printer.

Light reflects: Output=L Light does not reflect: Output=H

1 Paper

2 Paper Take-up Roller

3 Double Feed Sensor

1 Synchronizing Roller Sensor (PC2)

2 Paper

Loading...

Loading...