SECTION 12: BRAKE AND AIR SYSTEM

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual Section 12 revised Jan 2021

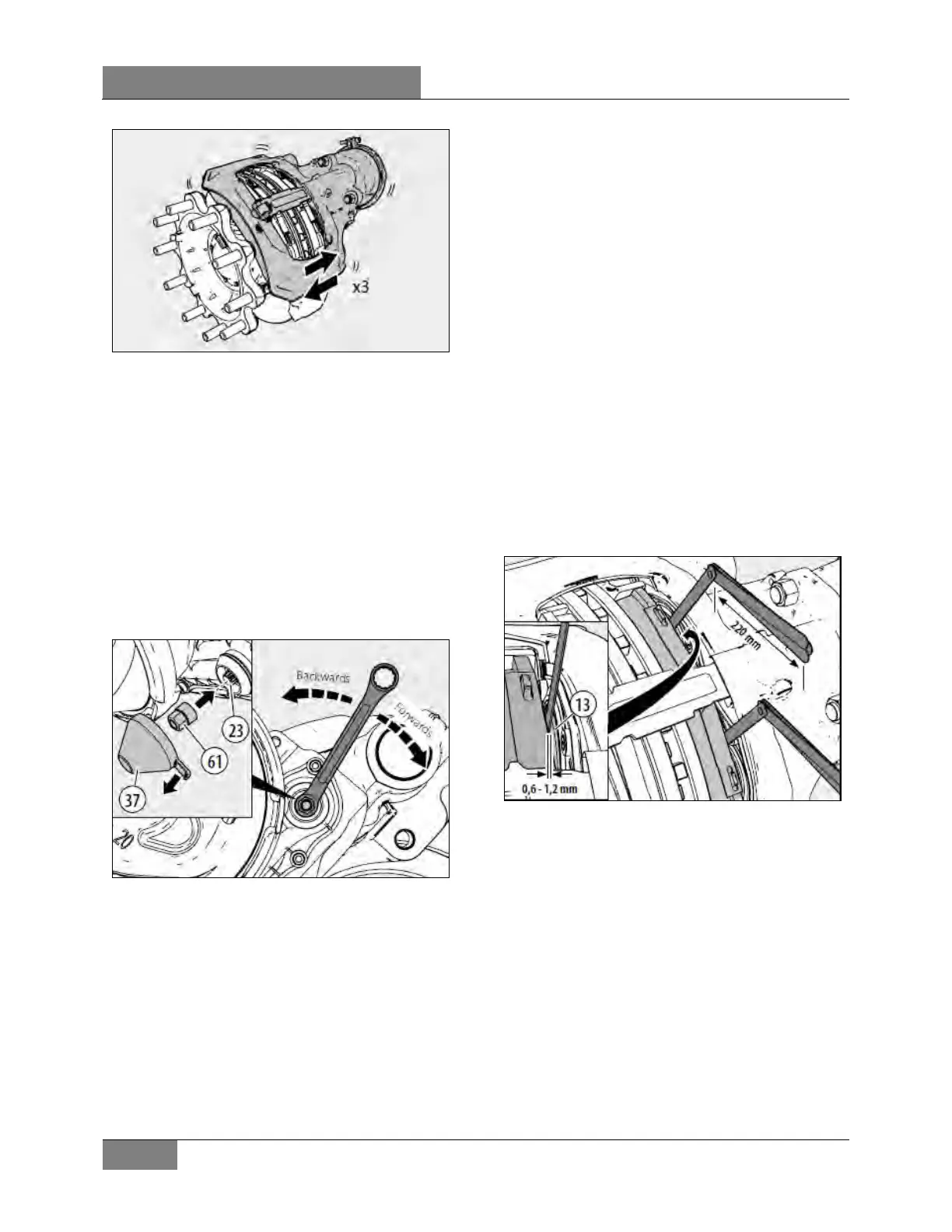

FIGURE 40: PUSH CALIPER THREE T IMES IN AXIAL

DIRECTION

6. Push and pull caliper three times in axial

direction to assess any existing air gap

(see Figure 40. If no movement is possi-

ble, clean the disc brake and if necessary,

replace the bearings. Once movement is

obtained, continue as follows:

7. Pull off the adjuster cap (37) using the

tag, taking care not to lose the shear

adapter (61) (see Figure 41).

Removal of the adjuster cap (37) with a

screwdriver, or similar, is not allowed since the

seal may be damaged.

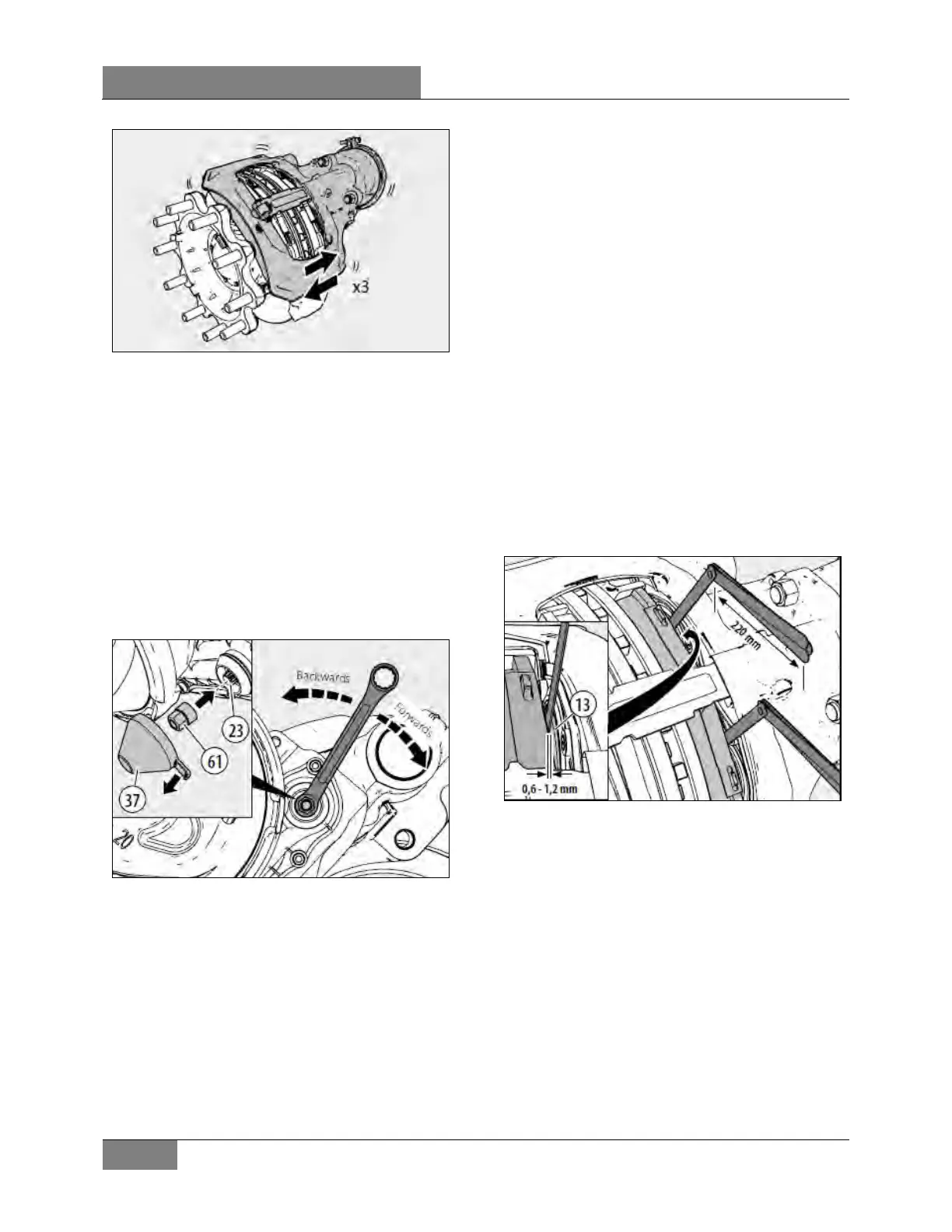

FIGURE 41: REMOVE CAP, INSERT NEW BRAKE PADS,

SET THE STARTING GAP

8. Insert new brake pads).

9. Set the starting gap by turning the

adjuster (23) with the shear adapter (61)

backwards and then forwards (note that

when turning backwards a noticeable

clicking can be heard and felt), until a

value of 0.051 in (1.3 mm) air gap has

been achieved (measure between the

brake pad and tappets (13).

10. Apply the brakes 20x with medium

pressure.

11. Check the gap between each of the

tappets (13) and inboard pad backplate

(12). This must be measured over the

whole tappet surface of both tappets us-

ing two feeler gages simultaneously (feel-

er gages must be at least 8 ½ in / 220

mm long) (see Figure 42).

12. If the gap difference between the two

tappets is > 0.009 in / 0.25 mm then the

caliper bearing clearance must be

checked (see 16.2.7 Caliper check -

Caliper Running Clearance & 16.2.8 Cal-

iper check - Caliper Movement Along

Guide Pins).

13. In addition, each gap must measure

between 0.023 - 0.047 in (0.6 - 1.2 mm).

If the clearance is too great, there is a danger

of brake failure. If the clearance is too small,

there is a danger of overheating that may lead

to consequential damage.

FIGURE 42: CHECK GAP BETWEEN TAPPETS AND

INBOARD PAD

If the air gap is larger than 0.047 in / 1.2 mm,

the adjuster must be checked as follows:

14. Turn the adjuster with adapter (61) 3

clicks anticlockwise (increasing the air

gap) (see Figure 43).

Make sure the ring spanner or socket can turn

freely clockwise during the following procedure.

Loading...

Loading...