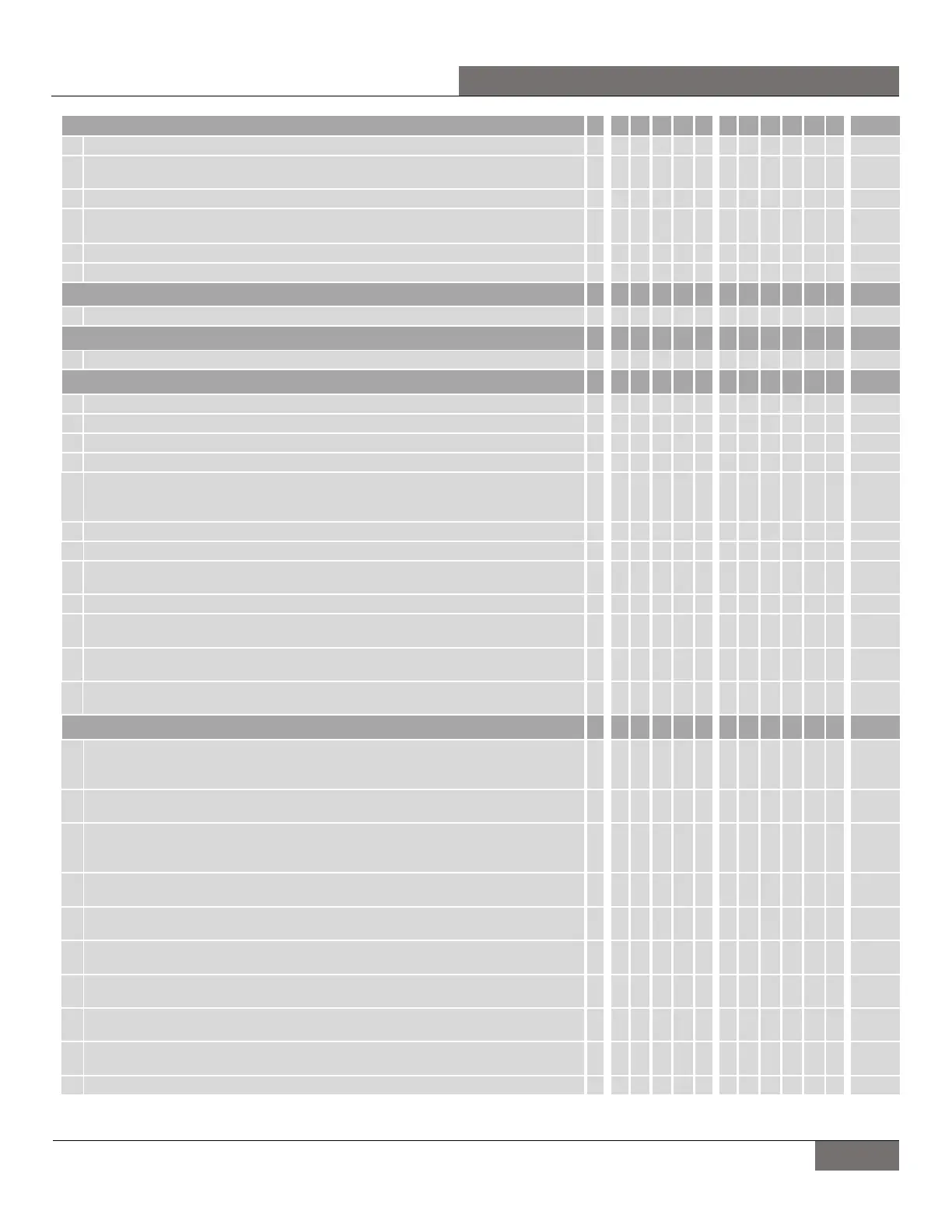

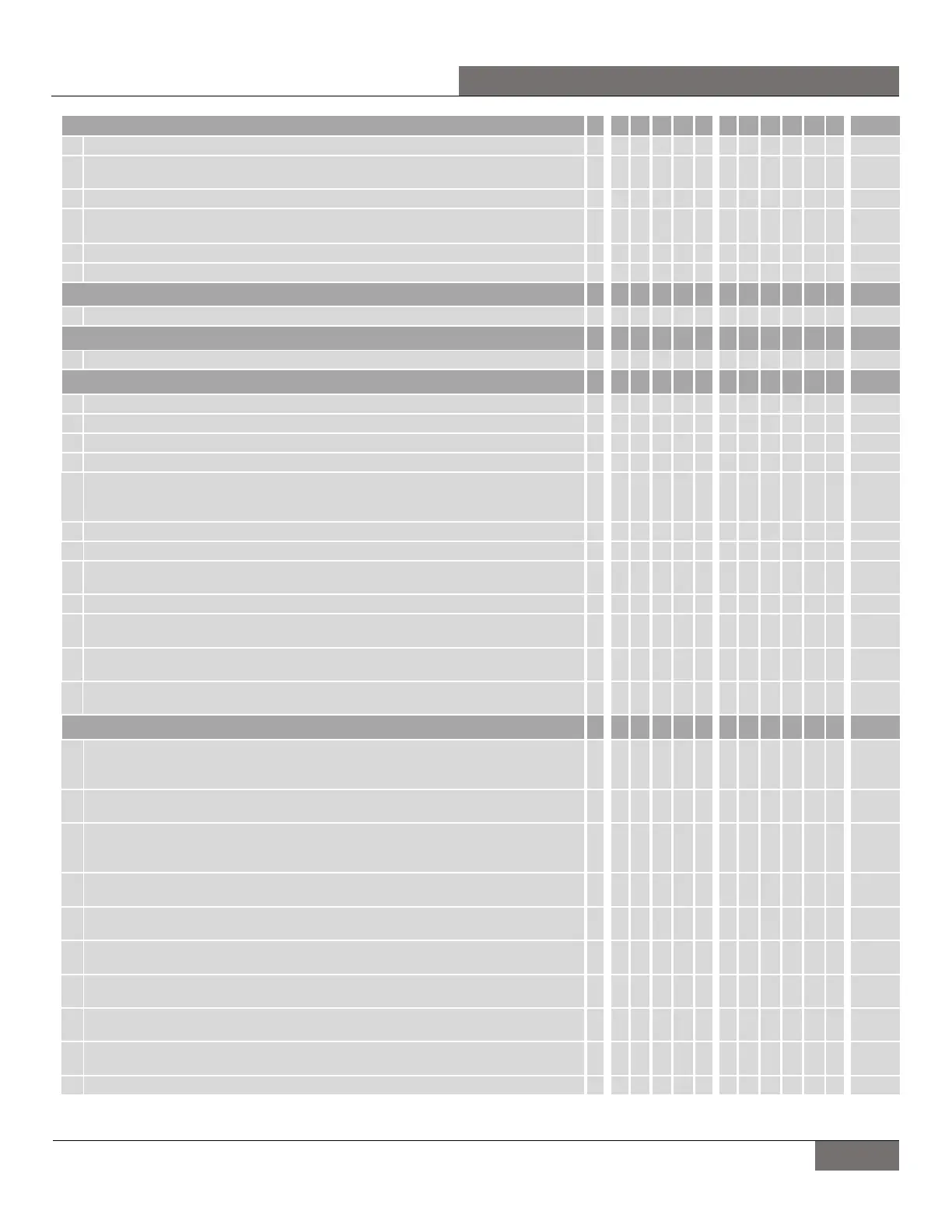

SECTION 24A : LUBRICATION & SERVICING SCHEDULE

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual section 24A revised Dec 2021

Drag link end ball joints – inspect for corrosion

Power steering fluid – check fluid condition (color) through visual

inspection and change if required. Check level, add if necessary

Power steering tank filter cartridge – replace

Tie rod – perform TIE ROD INSPECTION PROCEDURE (tube, ball joint, fine adjustment

sleeve, corrosion)

Steering system – perform STEERING SYSTEM PLAY INSPECTION

Power steering fluid – replace

Front bumper, exterior compartment door latches, grease fittings

22 HEATING & AIR CONDITIONING

Passengers HVAC unit disposable return air filters (2) – replace

Evaporator compartment door fresh air intake filter – replace

Parcel rack fans air filter – clean or replace

Driver HVAC unit return & fresh air filters – clean or replace

A/C compressor – check oil level, add if necessary. Change the oil if it has

darkened.

Refer to Oil Color And Level Check in Maintenance Information

A/C receiver tank – check refrigerant level, add if necessary

A/C compressor – empty shaft seal oil collection tube

Refrigerant moisture indicator – check, replace filter dryer unit according to

moisture indicator

Driver’s HVAC units – clean heater & evaporator cores with low-pressure air jet

Passengers’ HVAC unit – clean evaporator & heater cores with a stream of

low-pressure water or low-pressure air jet

Passengers’ HVAC unit – clean condenser core with a stream of low-pressure

water or low pressure air jet

A/C compressor – change oil, clean oil filter and magnetic plug every 4 years

(10 000 operating hours approximately)

AFSS extinguisher tank – proceed to the verification of the AFSS main

components, to do so, refer to

Checkout Procedure paragraph in Prevost

AFSS extinguisher tank –perform a fire system test and service the extinguisher,

refer to System Testing paragraph in Prevost Maintenance Manual

AFSS extinguisher tank – have the fire extinguisher rebuilt by a qualified fire

protection equipment company familiar with the extinguisher used

– every 6

AFSS extinguisher tank – have the fire extinguisher cylinder hydrostatically

tested by a qualified fire protection equipment company – every 12 years

Rotogrip snow chains – Inspect all parts for damage. Check all fasteners for

correct torque

Rotogrip snow chains – Check air lines, valve and solenoids for leak when the

system is engaged

Rotogrip snow chains – Inspect contact ring rubber and chain strands for wear

and replace when wear exceeds 50%

Rotogrip snow chains – Inspect inside sidewall of the tires. Tire wear indicates

misalignment or damage to the system.

Rotogrip snow chains – Check for proper chain wheel angle and position in

relation to the vertical centerline of the tire

Loading...

Loading...