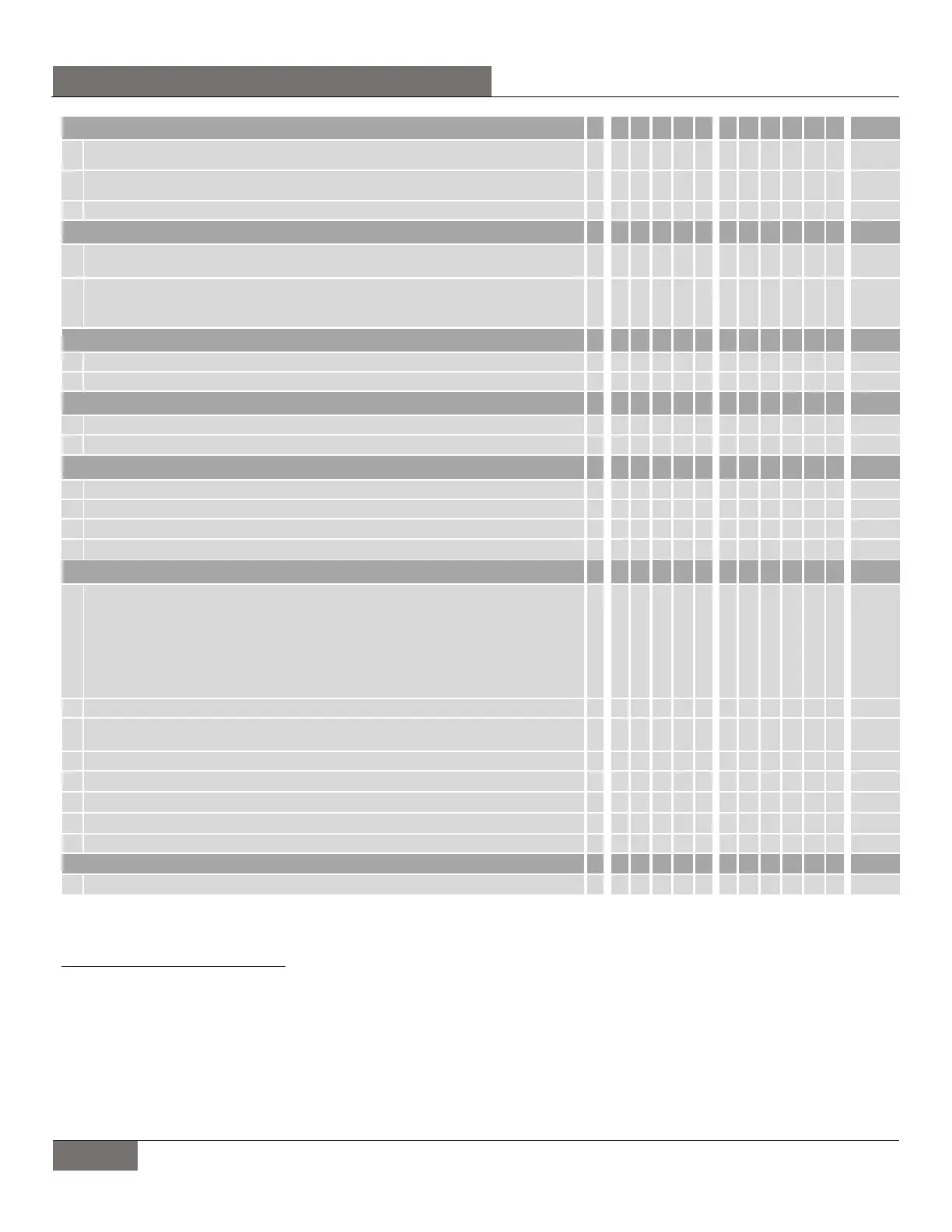

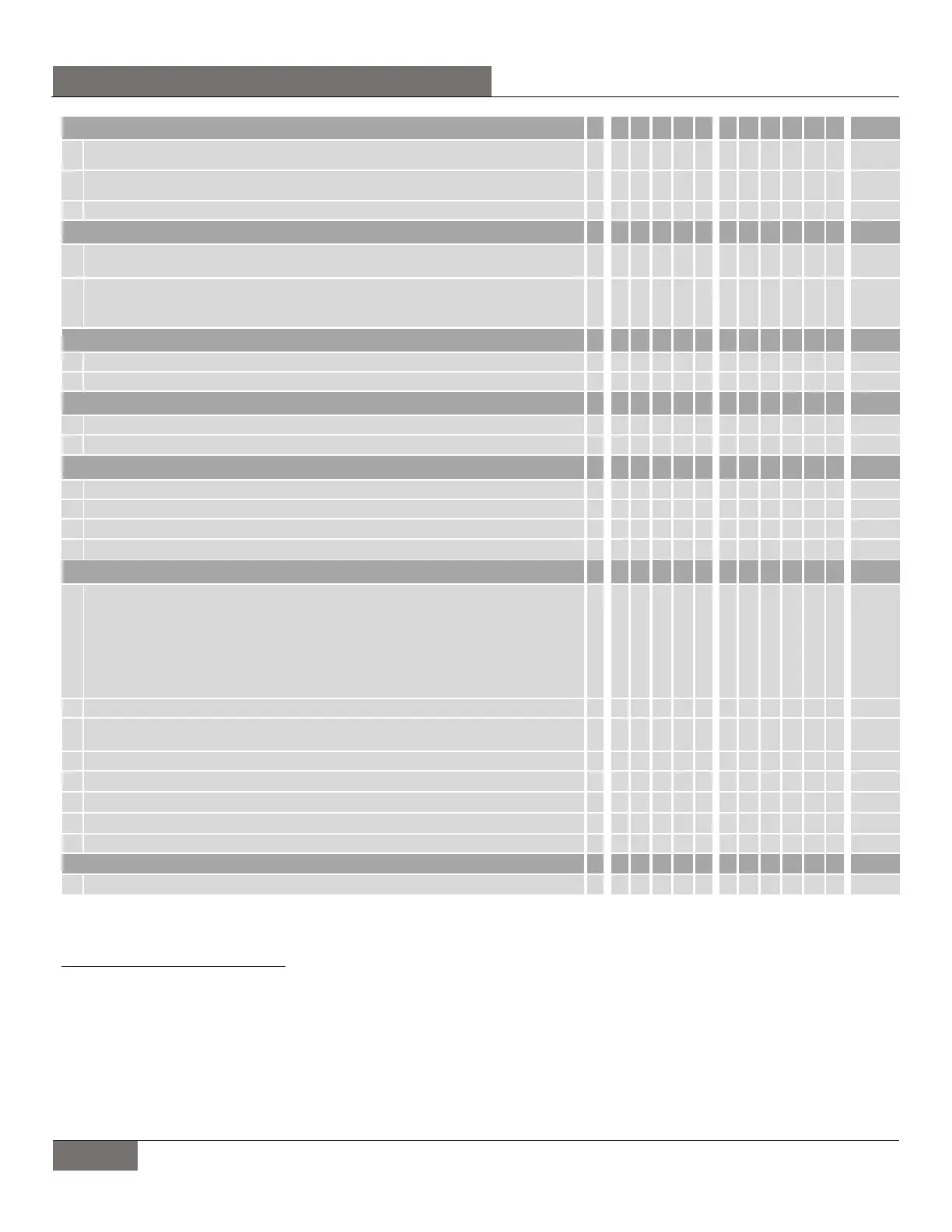

SECTION 24A : LUBRICATION & SERVICING SCHEDULE

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual section 24A revised Dec 2021

Bosch HD10 alternators drive belt – replace

Alternators – perform ALTERNATOR PERIODIC INSPECTION procedure

Battery terminals – clean & coat terminals

Severe vocation, filled with TranSynd or TES295 synthetic fluid only, no mixture

3

& using High–Capacity filters

4

. Transmission fluid – change every 84 000 miles

Severe vocation, filled with TranSynd or TES295 synthetic fluid only, no mixture

& using High

–Capacity filters. Transmission Main & Lube filters – change every

Perform Spicer’s Driveshaft “Inspection Procedures”

Grease one fitting on each universal joint

Steering knuckle (king) pins – grease two fittings per knuckle

Steering knuckle (king) pins – inspect

ZF Drive axle – check differential oil level, add if necessary

ZF Drive axle – change differential oil & breather

ZF Drive axle – check compact bearing axial play

ZF Drive axle – change grease in compact bearing (hub unit)

Brakes – (visual & functional check) check correct functioning of the adjuster,

check that caliper operates smoot

h

ly over its full range of movement, check the

adjuster cap for correct fitting and condition, check the sealing elements for

correct fittin

g and condition (ca

liper guide pin seals + tappet & boot assemblies),

check the caliper bearing in the area of the rubber bush/guide sleeve, check

caliper running clearance

, check fitting and condition of the cover

at brake pad

replacements or once a year whichever comes first

Brakes – check pad & disc wear

Air tanks – drain water from all tanks equipped with manual drain valve, including

the air dryer purge tanks (2x)

Haldex Consep Condenser/Separator – inspect

Accessories air filter – drain bowl

ABS & Electronic Stability Control systems – check proper functioning

Accessories air filter – change filter element

Air dryer – change two cartridges

Hub bearing, front and tag axle – inspect

2

Allison Transmission recommends that customers use fluid analysis as the primary method for determining fluid change intervals. In the absence of a

fluid analysis program, the fluid change interval listed in the chart above should be used. Change filters according to chart above even if a fluid

analysis shows that the fluid doesn’t need to be changed.

3

When the transmission contains a mixture of fluids (defined as the quantity of non-TranSynd or non-TES 295 fluid remaining in the transmission after

a fluid change combined with the quantity of TranSynd or TES295 required to fill the transmission to the proper level), perform the fluid & filter change

according to the TES389 intervals. Refer to the Maintenance Manual for TES389 intervals.

4

Extended TranSynd or TES 295 fluid & filter change intervals are only allowed with Allison High-Capacity filters.

Loading...

Loading...