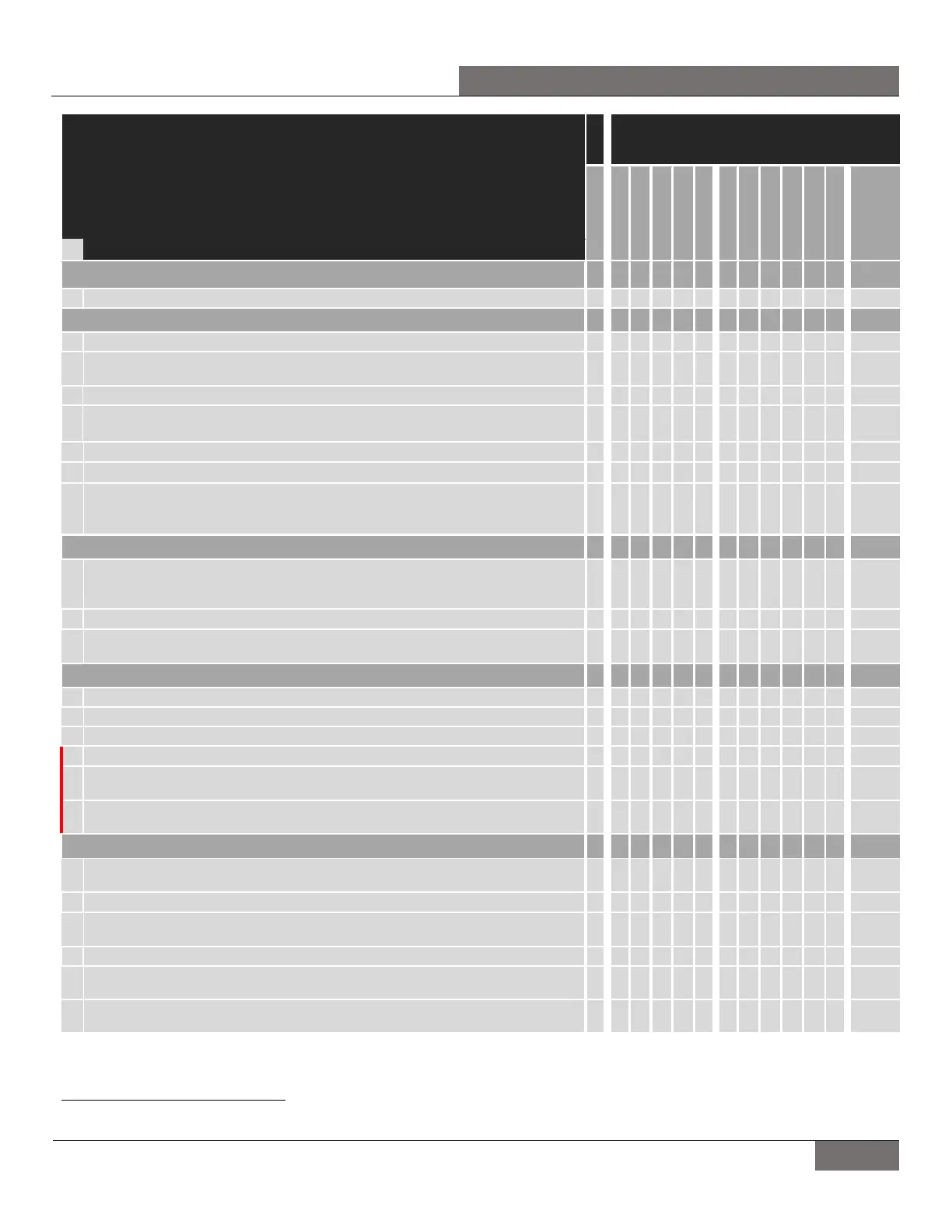

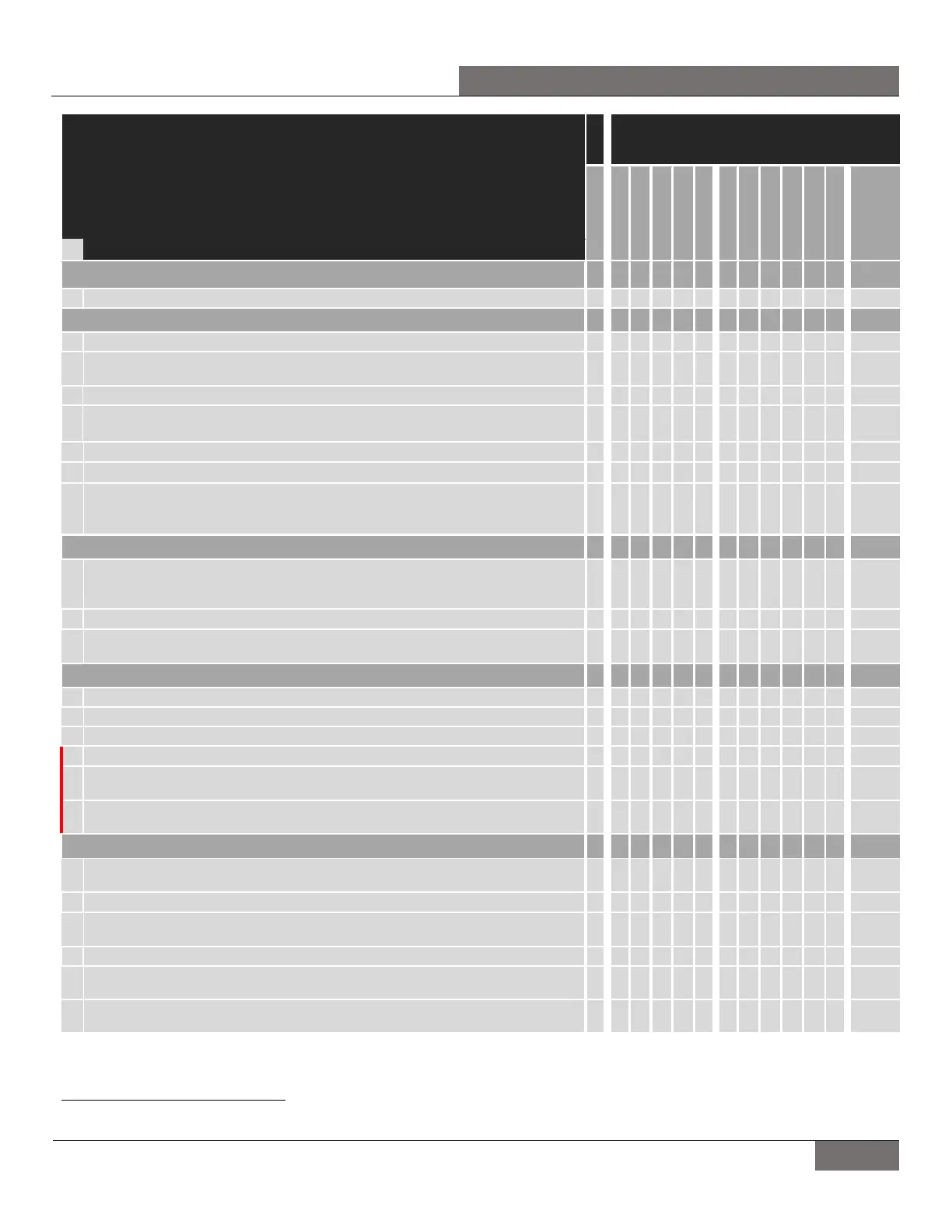

SECTION 24A : LUBRICATION & SERVICING SCHEDULE

DOB 1300-1556 | X3-45 Commuter PA-1648 Maintenance Manual section 24A revised Dec 2021

LUBRICATION AND SERVICING SCHEDULE

X3–45 Commuter DOB 1300-1606

Proceed to maintenance operation

every (miles)

1

#

SECTION

Flexible hoses – thoroughly inspect all hoses

Engine oil & filter – heavy operation condition, change

Drive belts and idlers – visually inspect for signs of deterioration, cracks or

frayed material

Air cleaner – replace filter element when indicated by air filter restriction indicator

or according to this interval whichever comes first

28

Valves & injectors – initial adjust at 36 000 miles (2 500 hrs)

Valves & injectors – check & adjust every 72 000 miles (5 000 hrs)

Automatic belt tensioners & idler pulleys inspection – remove belts, check for

no

isy bearings, play, bushing play. Perform AUTOMATIC BELT TENSIONER AND

IDLER PULLEYS INSPECTION procedure

Davco Fuel Pro 382 primary fuel filter – Perform visual check of fuel level in

the clear cover. Change the filt

er when the fuel reaches the top of the

“CHANGE FILTER” lettering on the clear cover

Secondary fuel filters – change at every engine oil change

Fuel tank and cradle visual inspection – perform yearly inspection. Refer to Fuel

Tank Yearly Inspection

04 EXHAUST AND AFTERTREATMENT SYSTEM

DEF tank – clean filler neck strainer

DEF tank – drain & clean with water

DEF pump filter element – replace

DPF filter – either clean or replace every 36 000 miles

Diffuser assembly, rain cap & drain tube – check proper functioning & clean

every 36 000 miles

Aftertreatment Hydrocarbon Injector (a.k.a. AHI doser) – change every 36 000

miles

Coolant filter housing shutoff valve – rotate the handle periodically to keep

spindle rotation smooth

Coolant surge tank – test coolant solution

Coolant filter – change (Long-Life filter without additives to be used with

Extended Life Coolant)

Radiator – inspect exterior core & clean with low pressure water jet if necessary

Coolant filter housing shutoff valve spindle – apply fresh grease at cooling

system drain

Cooling system – drain, flush & refill (using Extended Life Coolant) every

750 000 miles

C /

1

= Specialty tool required. You will find the SPECIALTY TOOLS REQUIRED FOR REGULAR MAINTENANCE table and the LUBRICANTS

SPECIFICATIONS table following this Lubrication and Servicing Schedule.

Loading...

Loading...