4A-4 FRONT DRIVE SHAFT

Installation

1) To carry out install of assemblies, reverse removal

procedures, noting remarks and tightening torques:

• Inspect the worthiness of the oil-seal and substitute it if

damage, wear or deformations are observed.

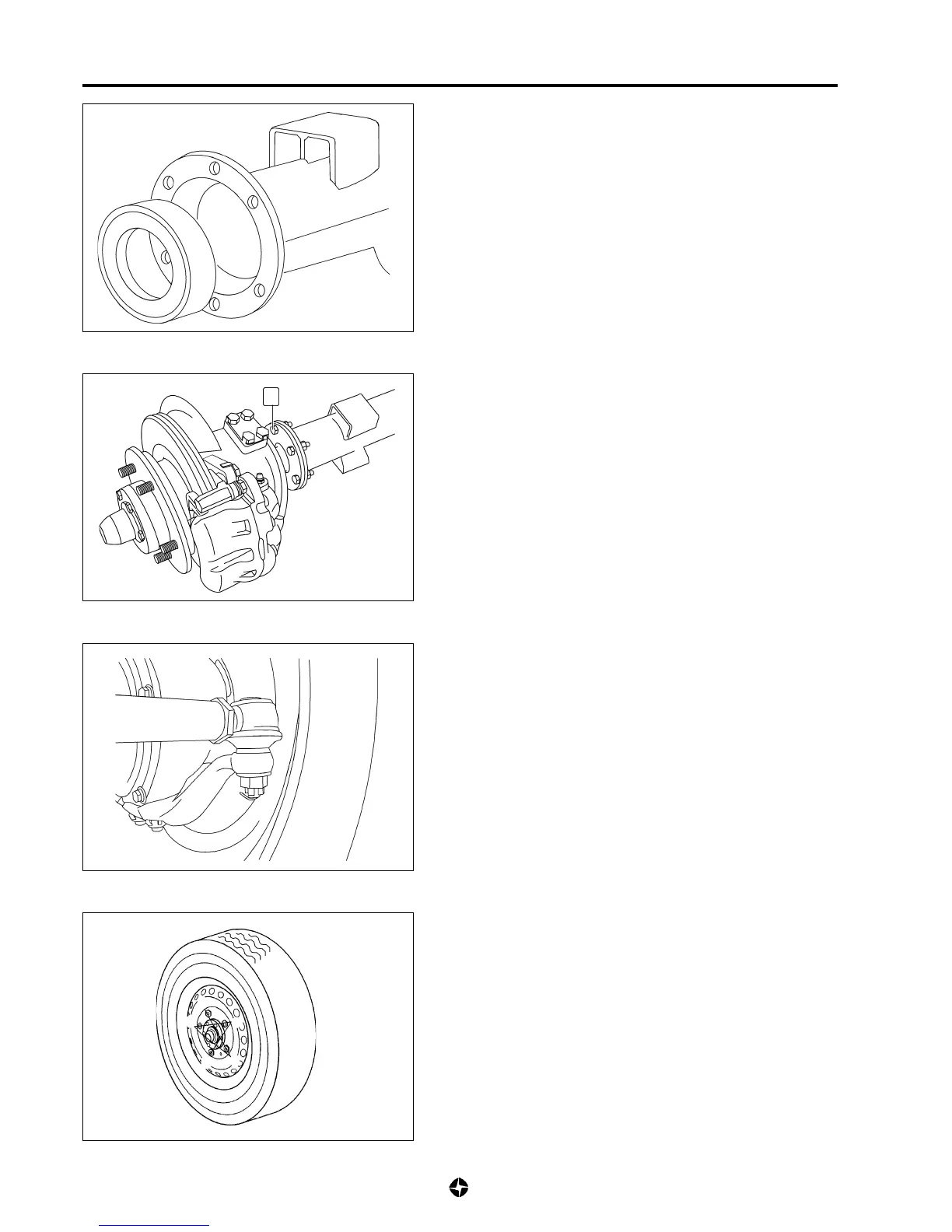

• Ensure that faces of the couplings between the housing

flange and hemisphere flange are clean.

• Apply grease to lip of oil-seal enclosure.

5

• Apply recommended sealant to the faces of the coupling

between the housing flange and the hemisphere flange.

Fixing elements (5) connecting bridles tightening

torque:

3,5 ÷ 4,25 Kg-m (35 ÷ 42,5 Nm)

NOTE:

Install new self braking nuts in the flange unions.

• Tighten to the specified tightening torque nut fixing tie rod

end joint and block it with pins.

Nuts fixing ball and socket joints tightening torque:

4 Kg-m (40 Nm)

• Apply recommended sealant to nuts fixing brake caliper

and tighten them to the specified tightening torque.

Tightening torque for screws fixing brake clamps to

support:

3,1 ÷ 3,5 Kg-m (31 ÷ 35 Nm)

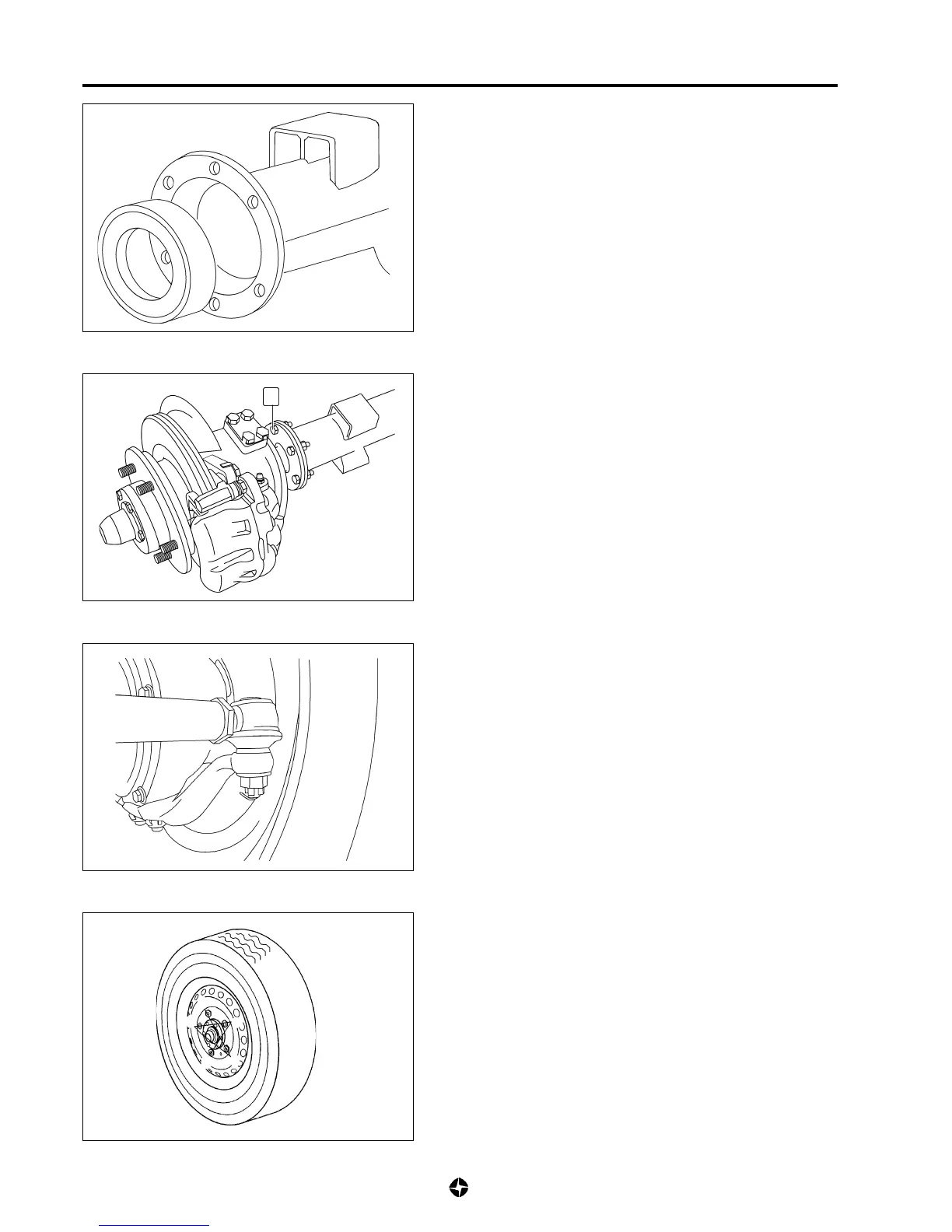

• Tighten wheel nuts to the specified tightening torque following

the steps sequence shown in the figure.

Tightening torque for wheel screws:

11 ÷ 17Kg m (110 ÷ 117Nm)

1

4

2

5

3

Loading...

Loading...