0B-8 MAINTENANCE AND LUBRICATION

Injectors gauging (Item 1.4)

(ONL(ONL

(ONL(ONL

(ONL

Y MECHANICAL INJECTION)Y MECHANICAL INJECTION)

Y MECHANICAL INJECTION)Y MECHANICAL INJECTION)

Y MECHANICAL INJECTION)

Data for injectors gauging

BOSCH type sprayer

Gauging controls below 200 bars

Running Gauging

SACLESS DSLA

134 P 604

230 + 8 bar

240 + 12 bar

Control

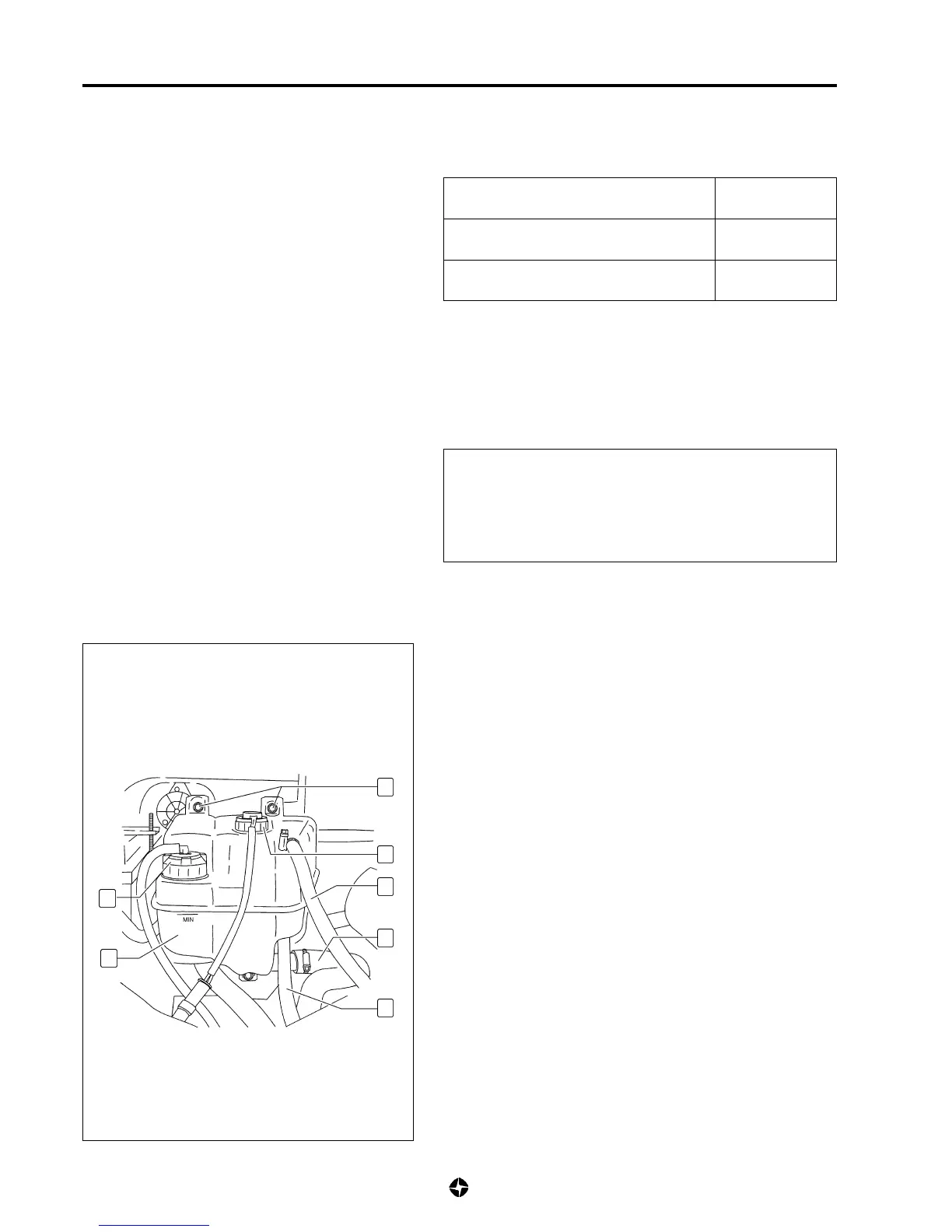

Unlock cap (1) of the expansion vase, letting inside the adequate

densitometer and check that the refrigerant contains no less

than 40% protector; otherwise substitute it.

Inspection

1) With an appropriate pressure pump check that cap (1) of

the tank holds pressure till 0,7 Kg (pressurizing circuit);

otherwise, replace the cap.

2) Check visually there are no leaks, the worthiness of the

sleeves and the tightness of the braces.

3) If you detect mud or dirt within the expansion vase, you

must clean it as follows:

Unlock or disconnect:

• Filling cap (1), level gauge (4), radiator degasifier sleeve

(5), filling sleeve (6), engine degasifier sleeve(7) and tank

(2) fixing nuts (3).

• Withdraw tank (2), wash it with pressurized water and

appropriate detergent, rinse it well and fix it again working

in reverse order.

4) Proceed to fill as explained below, warm engine at the running

temperature and check there are no leaks.

1

2

7

6

5

4

3

Engine Coolant (Item 1.5)

(Control, inspection, substitution and level)

WARNING:

To avoid burnings, do not open the expansion vase

while engine and the radiator are hot; high temperature

liquid and vapours could be spouted and bring about

serious bodily harm.

Loading...

Loading...