ENGINE FUEL AND EMISSION CONTROL SYSTEM 6C-25

GENERAL DESCRIPTION

A piston pump supplies the fuel at a regular pressure

equivalent to that of the injection (up to 1350 bar).

A two-way electro-valve takes from the pump supply, the

appropriate amount of fuel to regulate the desired pressure

value.

The pressurised fuel accumulates in a collector (rail) which

contains the pressure oscillations (ripple).

The electro-injectors are fed by the rail and their working is

determined by the stimulation of a rapid electromagnetic

operator (integrated in the body of each electro-injector)

opening an aperture which causes a pressure difference.

This difference allows the opening of the injector end

producing the spray.

An electronic control unit, in which the control and power

units for the electro-injector piloting are integrated, is

prepared for the control of the entire injection system.

Some sensors, connected to the control board, can deter-

mine the state of the engine and the injection system at

every moment as well as the demand for power by the

driver.

Moreover, the system can control an operator for the EGR

and for the turbocompressor with waste-gate, or a variable

geometry turbocompressor.

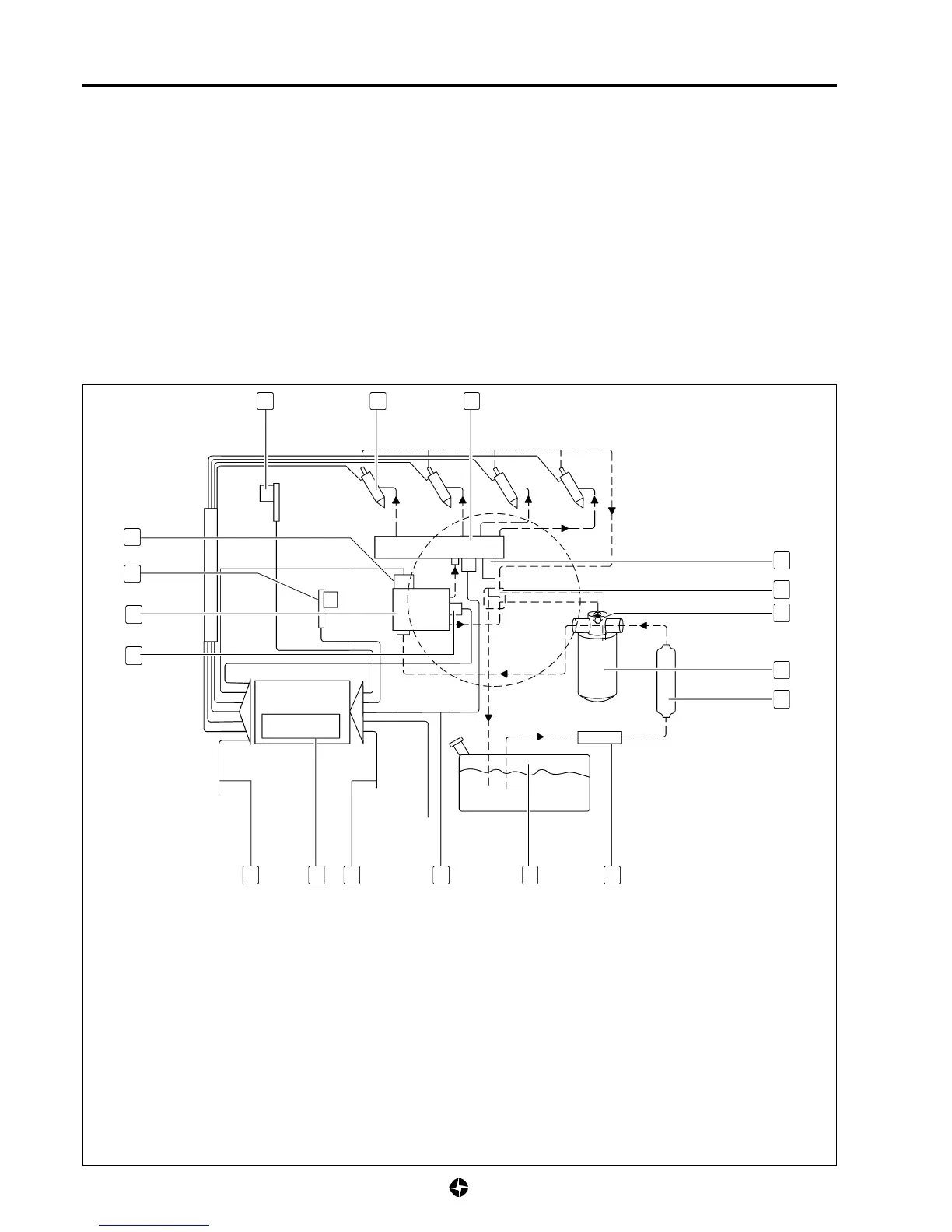

HIGH PRESSURE ELECTRONIC INJECTION SYSTEM FUNCTIONAL DIAGRAM

1.- 3

rd

pinston deastintor valve

2.- Crankshaft position sensor

3.- High pressure pump

4.- Pressure regulator

5.- Other actuators (thermostarter, fuel heater, electro-fan control, air-

conditioning compressor control)

6.- Electronic control unit with atmospheric pressure sensor

7.- Other sensors (accelerator, brake, clutch, vehicle speed, water

temperature, admission air temperature)

8.- Hydraulic accumulator (Rail) pressure sensor

9.- Fuel tank

10.- Prefilter

11.- Fuel supply electro-pump

12.-Fuel filter

13.-Filter over-pressure valve

14.- Multiple connector for excess fuel (5-way)

1

2

3

4

5 6 7

8 9 10

11

12

13

14

15

161718

15.-Hydraulic accumulator (rail) pressure limiter

16.-Hydraulic accumulator (Rail)

17.-Electro-injectors

18.-Camshaft position sensor

Loading...

Loading...