6C-34 ENGINE FUEL AND EMISSION CONTROL SYSTEM

ELECTRO-INJECTORS

Generalities

The electro-injectors are made to receive a supply at high pressure

(up to 1350 bar) and a recycling of atmospheric pressure,

necessary for the operation of the pilot valve.

The temperature of the recycled diesel can reach high

temperatures (120ºC).

The top part of the electro-injector has a moulding for electric

coupler fixing.

The electro-injectors are fitted in the caliper head and are

controlled by the control unit.

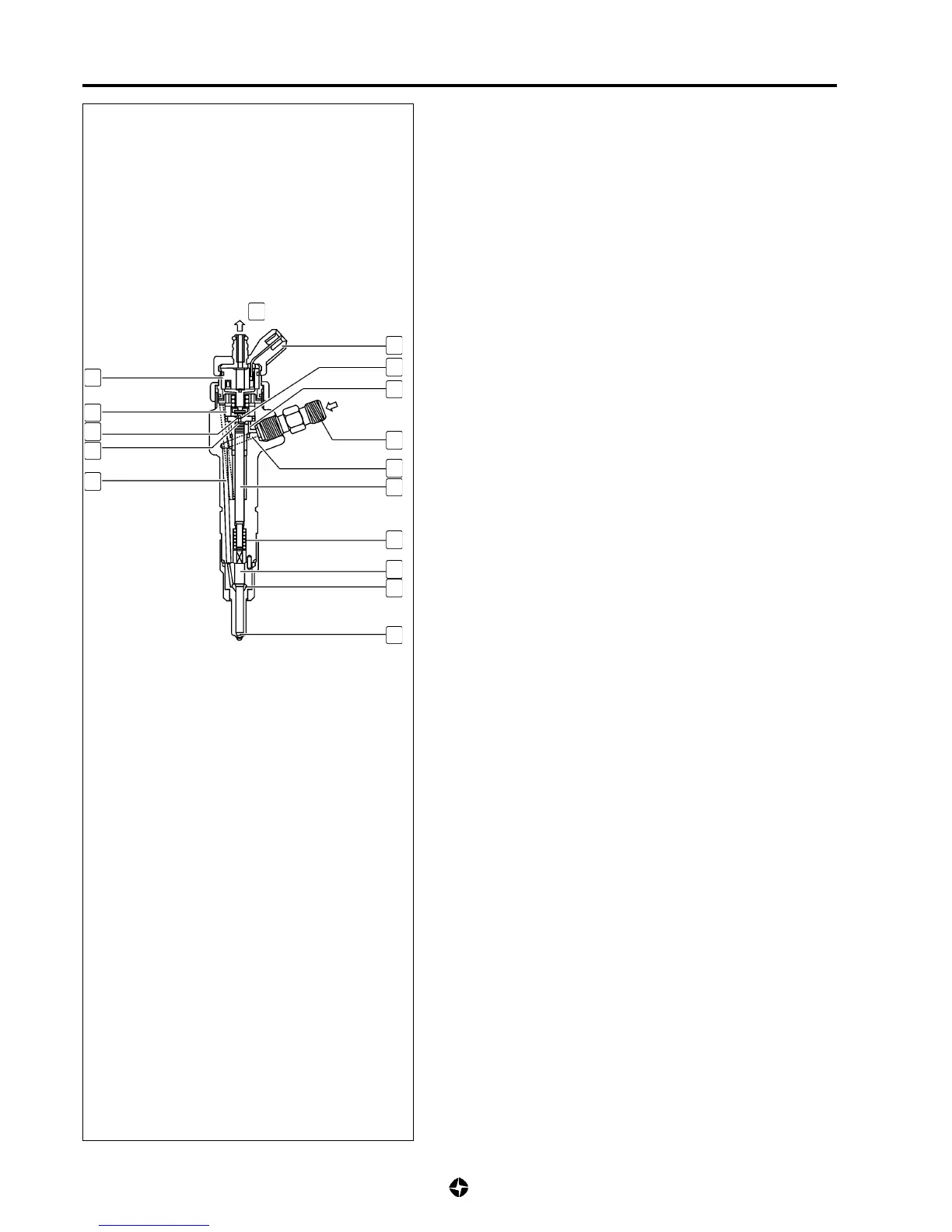

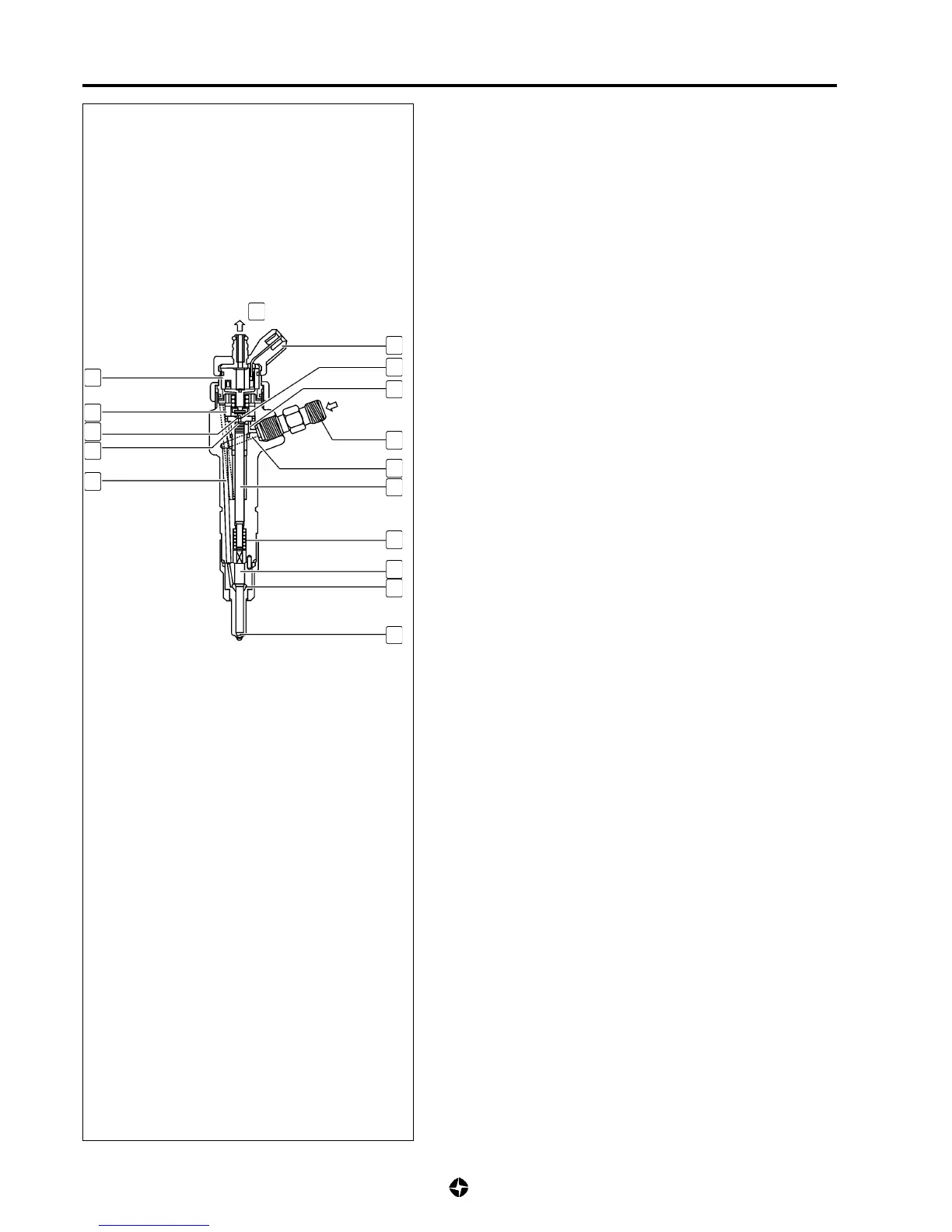

They can be divided into two parts:

- spray - composed of the pressure rod (1), the spigot (2) and

the injector (3)

- electro-valve control - composed of the reel (4) and the pilot

valve (5).

Functioning

The functioning of the electro-injector can be divided into three

stages:

- "Rest position"

The reel (4) is not stimulated, the stopper (6) is in the closed

position and does not allow the introduction of fuel into the

cylinder. Fc>Fa (Fc: due to the in-line pressure which acts on

the control area (7) of the rod (1); Fa: due to the in-line pressure

which acts on the supply volume (8)).

- "Start of injection"

The reel (4) is stimulated and raises the stopper (6). The fuel

from the control volume (9) flows to the return collector (10)

causing a decrease in pressure in the control area (7).

At the same time, the in-line pressure through the supply conduct

(12) exercises in the chambre (8) a force Fa>Fc, raising the

spigot (2) with consequent introduction of fuel to the cylinders.

- "End of injection"

The reel (4) is not stimulated causing the stopper (6) to return to

the closed position, recreating a balance of forces making the

spigot r (2) return to its closed position and thus finishing the

injection.

Map of injector quota

The map of injector quota is the group of characteristics "amount

of fuel injected according to the duration of the electric signals

to various injection pressures". Precise knowledge of such

characteristics is of fundamental importance to determine the

necessary electrical signal in order to inject the required amount

of fuel.

4

5

6

7

12

13

9

11

14

12

1

15

2

8

3

10

ELECTRO-INJECTOR

1.- Drive rod

2.- Spigot

3.- Injector

4.- Reel

5.- Pilot valve

6.- Spherical stopper

7.- Control area

8.- Supply chamber

9.- Control volume

10.- Fuel return

11.- Control conduct

12.- Fuel conduct

13.- Electrical connection

14.- Fuel inlet (high pressure)

15.- Spring

Loading...

Loading...