MAINTENANCE AND LUBRICATION 0B-13

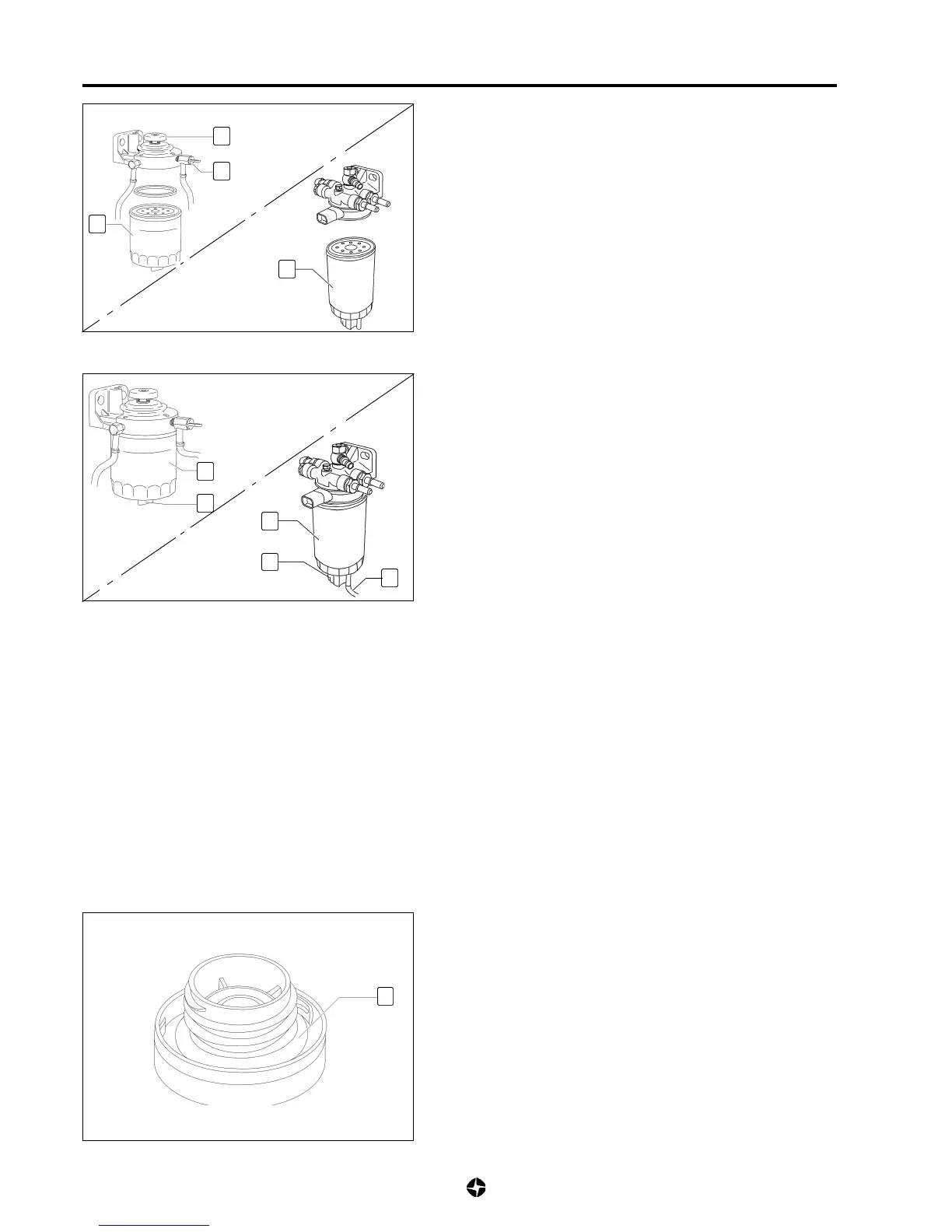

FUEL SYSTEM (Item 2)

Fuel filter and air purge (Item 2.1)

•

MECHANICAL INJECTION MECHANICAL INJECTION

MECHANICAL INJECTION MECHANICAL INJECTION

MECHANICAL INJECTION

To substitute the filter element (1), as well as to air purge

with pump (2) through purger (3), see 6C-8

"MANIPULATING THE FUEL FILTER ".

•

COMMON RAILCOMMON RAIL

COMMON RAILCOMMON RAIL

COMMON RAIL

To substitute the filter element (1), see 6C-8

"MANIPULATING THE FUEL FILTER ".

Water Purging and residues from the fuel filter

(Item 2.2)

•

MECHANICAL INJECTIONMECHANICAL INJECTION

MECHANICAL INJECTIONMECHANICAL INJECTION

MECHANICAL INJECTION

Open purger (4), draw the water and residues at the bottom

of the filter (1); close the purger when the fuel comes out

clean.

•

COMMON RAILCOMMON RAIL

COMMON RAILCOMMON RAIL

COMMON RAIL

Uncouple electrical connector (5) from the water sensor

(4

1

). Untighten the sensor a few turns until the accumulated

water in the filter draws out of the little drainpipe the sensor

has; moderately tighten the sensor when the fuel comes

out clean and couple the electrical connector (5) again.

Fuel Lines and connections (Item 2.3)

Inspection

1) Check visually the worthiness of the flexible tubings and

sleeves from the feeding and back return fuel lines; no

deformations, fissures, loses or rubbings should be apparent.

Substitute or replace if necessary.

2) Check visually the worthiness of braces and sleeves

connections to rigid pipes, and be sure that they are firmly

tightened.

3) Inspect the pathways of rigid tubings and sleeves, as well

as its arrangement along the left side of the frame; they

must be perfectly held with their braces, without rubbing in

between or with metallic parts which could bring damages.

1

3

2

1

4

1

1

1

1

1

4

1

5

MECHANICAL INJECTION

COMMON RAIL

MECHANICAL INJECTION

COMMON RAIL

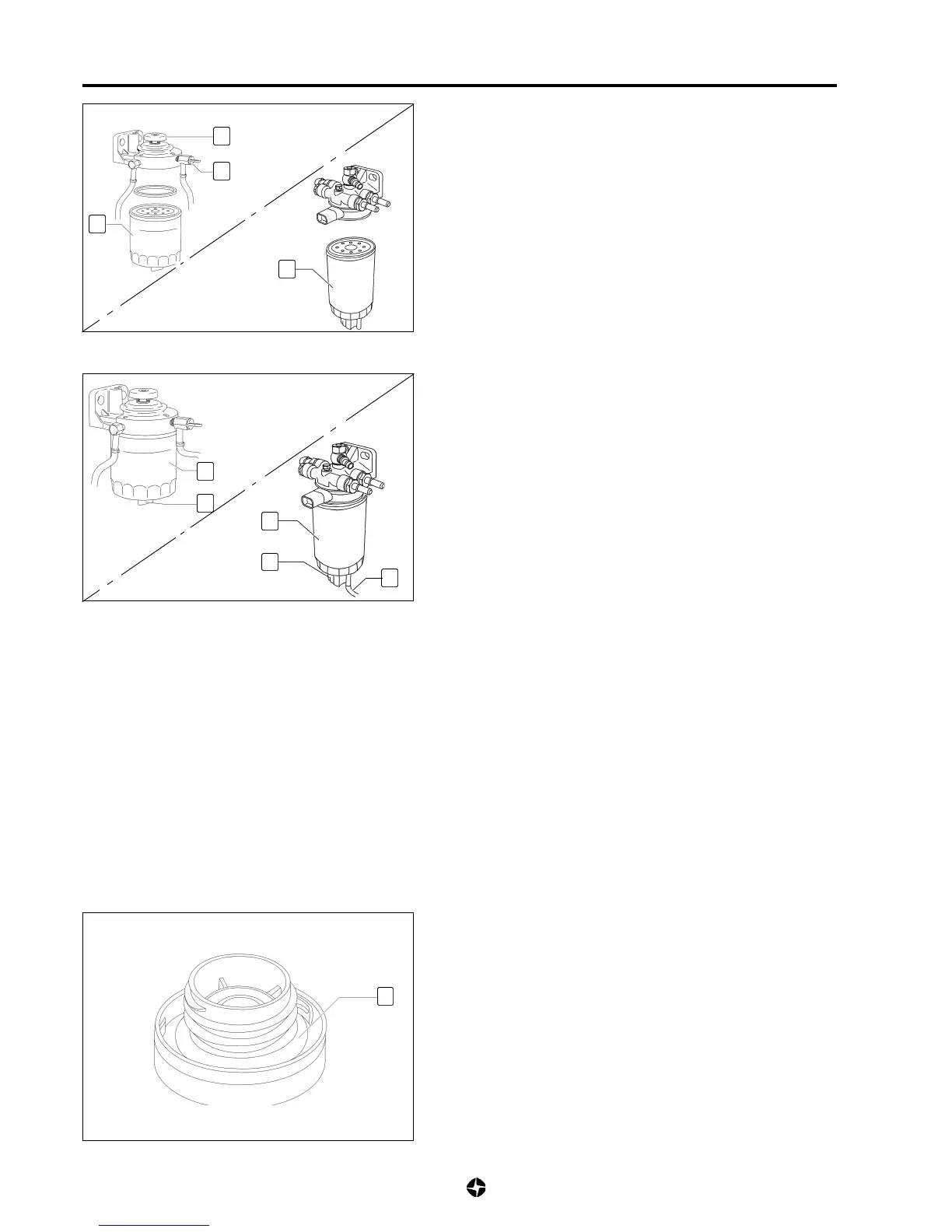

Fuel tank (Item 2.4)

Inspection

1) Check visually the worthiness of the cap joint (1), to ensure

no damages, deformations or excessive hardening occur;

replacing it if necessary.

2) Check the worthiness of the sleeves of the tank, ensuring

no deformations, cracks, loses or rubbings take place,

replacing if necessary.

3) Check the braces worthiness ensuring tightness of fittings.

4) Inspect the tank general looks, paint, scratches, knocks,

etc ... If there are any damages, gauge the seriousness of

damages and repair or substitute.

Loading...

Loading...