6A-32 ENGINE REPAIR

REMOVAL AND INSTALLATION OF INJECTORS

(mechanical injection engine)(mechanical injection engine)

(mechanical injection engine)(mechanical injection engine)

(mechanical injection engine)

CAUTION:

Before starting to remove, clean carefully all the

components to be removed or disconnect then as well

as surroundings.

Removal

1) Disconnect battery.

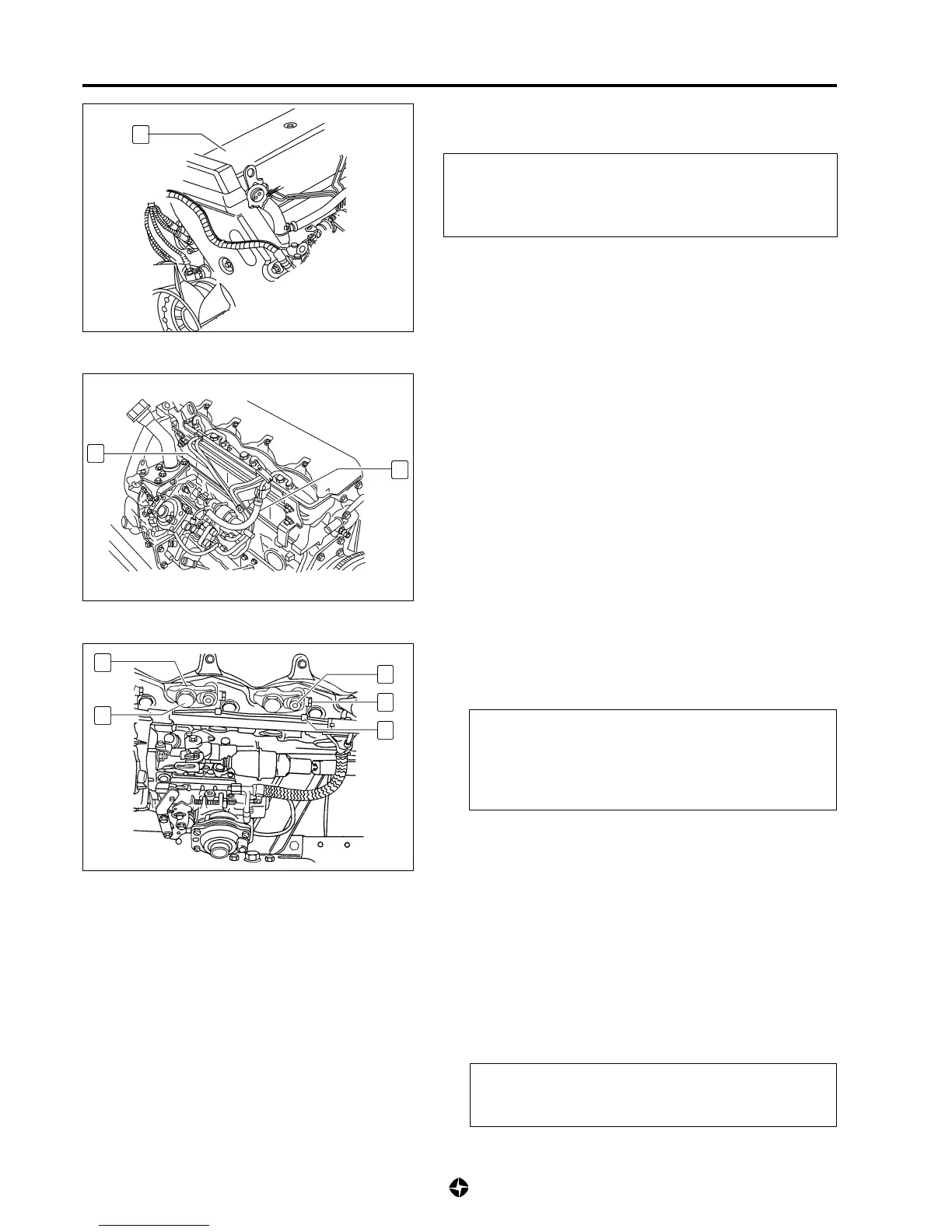

2) Remove sound proofing upper cover (1).

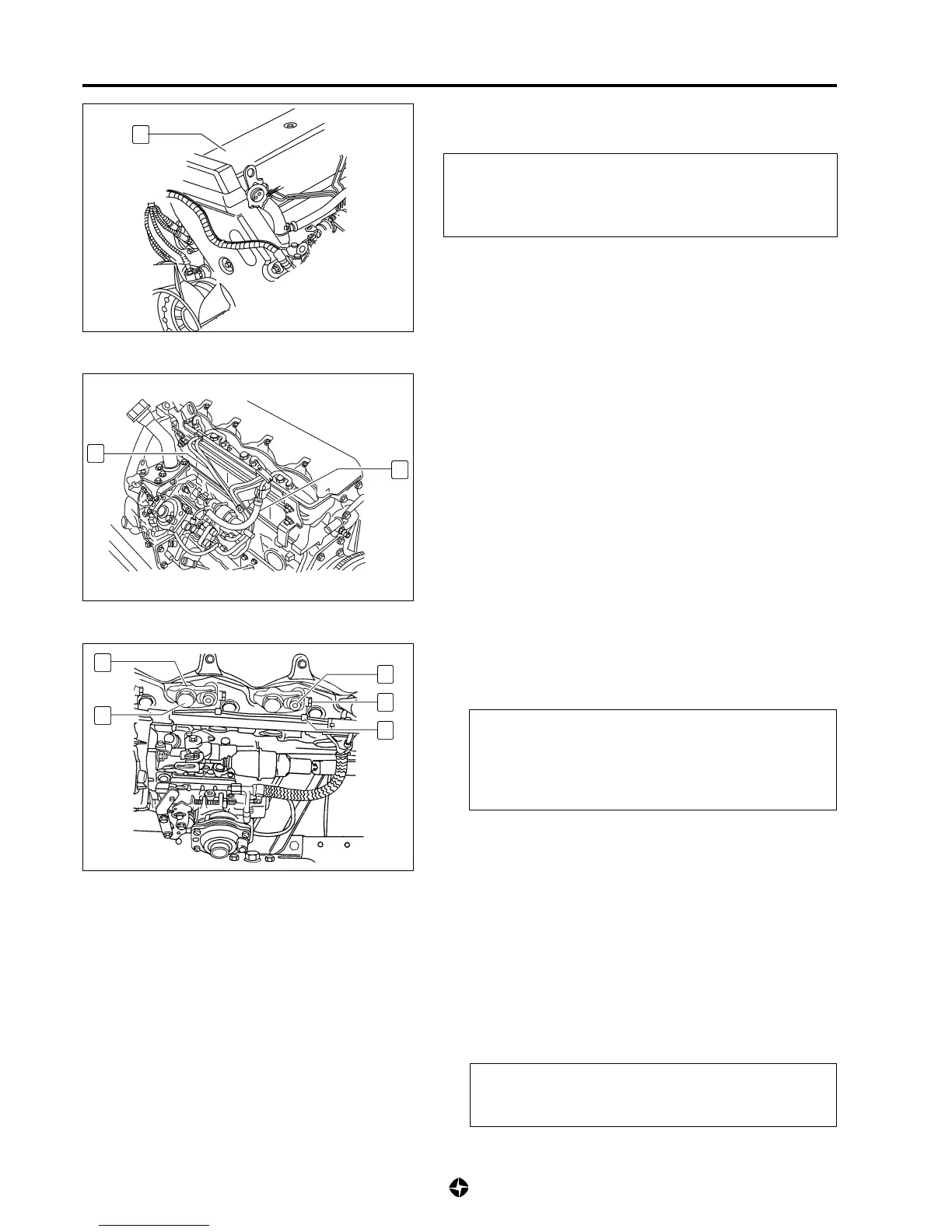

3) Remove fuel injection pipes (2).

4) Disconnect fuel return hose (3).

1

5) Remove linkages (7) and withdraw fuel remaining pipe (8).

6) Remove screws (5), remove fixing braces (4) and withdraw

injectors (6).

CAUTION:

Plug with appropriate caps the conductions which

have been opened. Entrance of some alien body in

this conductions could seriously damage the

injection system.

2

3

4

5

8

7

6

Installation

1) Reverse removal procedures, applying the specified

tightening torque.

Tightening torques:

• Braces screws (5): 4 Kg-m (40 Nm)

• Injection pipes linkages (2): 3,3 Kg-m (33 Nm)

• Nuts at sound proofing upper lit: 0,5 Kg-m (5 Nm)

• Linkages of injectors return pipes: 0,7 Kg-m (7 Nm)

CAUTION:

Install new impermeability gasket each time you

remove.

2) Purge the circuit (see 6C-8).

Loading...

Loading...