6A-26 ENGINE REPAIR

ON-VEHICLE SERVICE

BELTS SUBSTITUTION

Water pump and generator driving belt

substitution

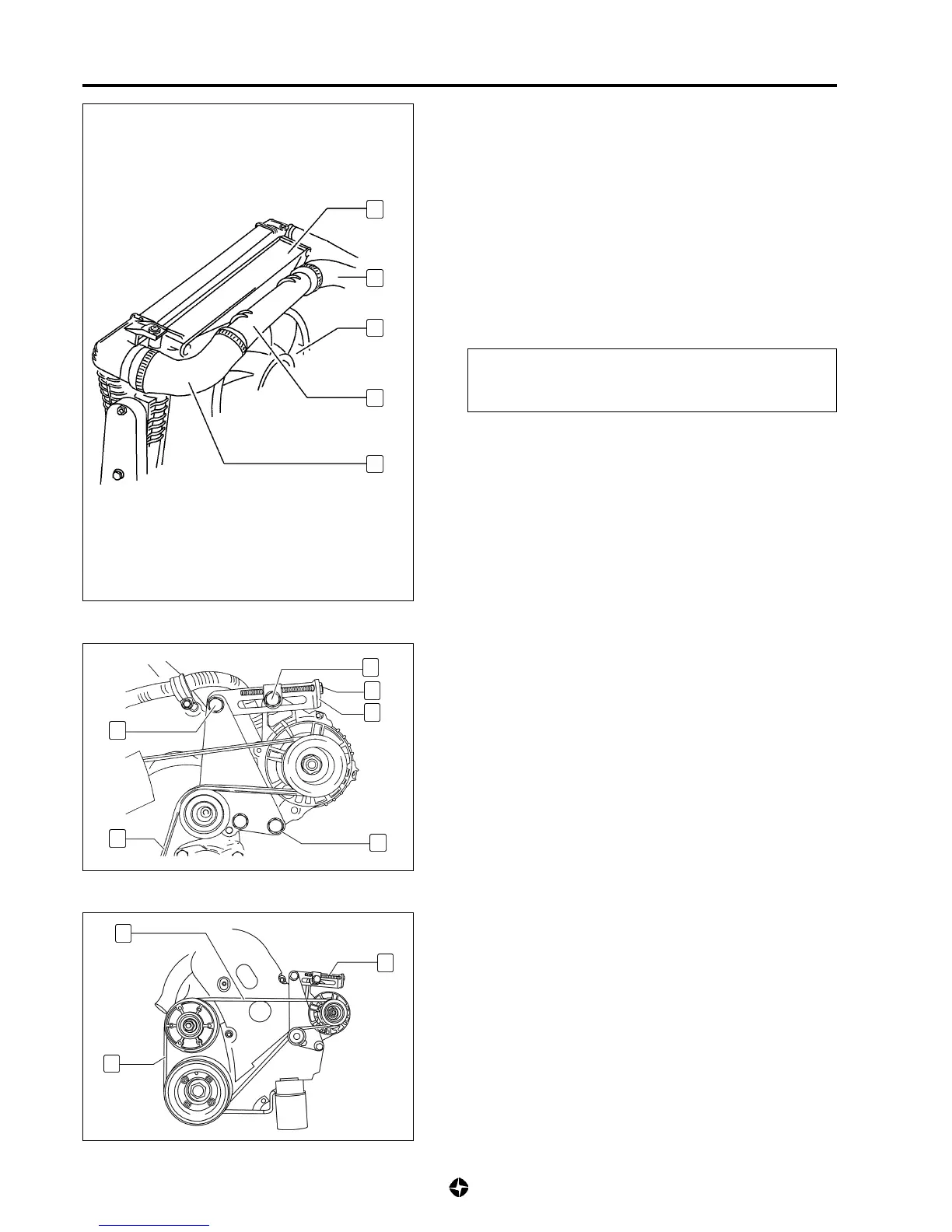

Removal

1) Disconnect battery.

2) Disconnect hoses (5) and (1) from interconnecting tube (4).

CAUTION:

Plug adequately hoses and interconnecting tube to

avoid alien bodies entrance while repairing.

3) Dismantle interconnecting tube (4).

4) Dismantle screws fixing air conduct (2) and move it towards

the engine.

5) Dismantle screws fixing fan (3); withdraw it and air

conduct (2).

2

1

3

4

5

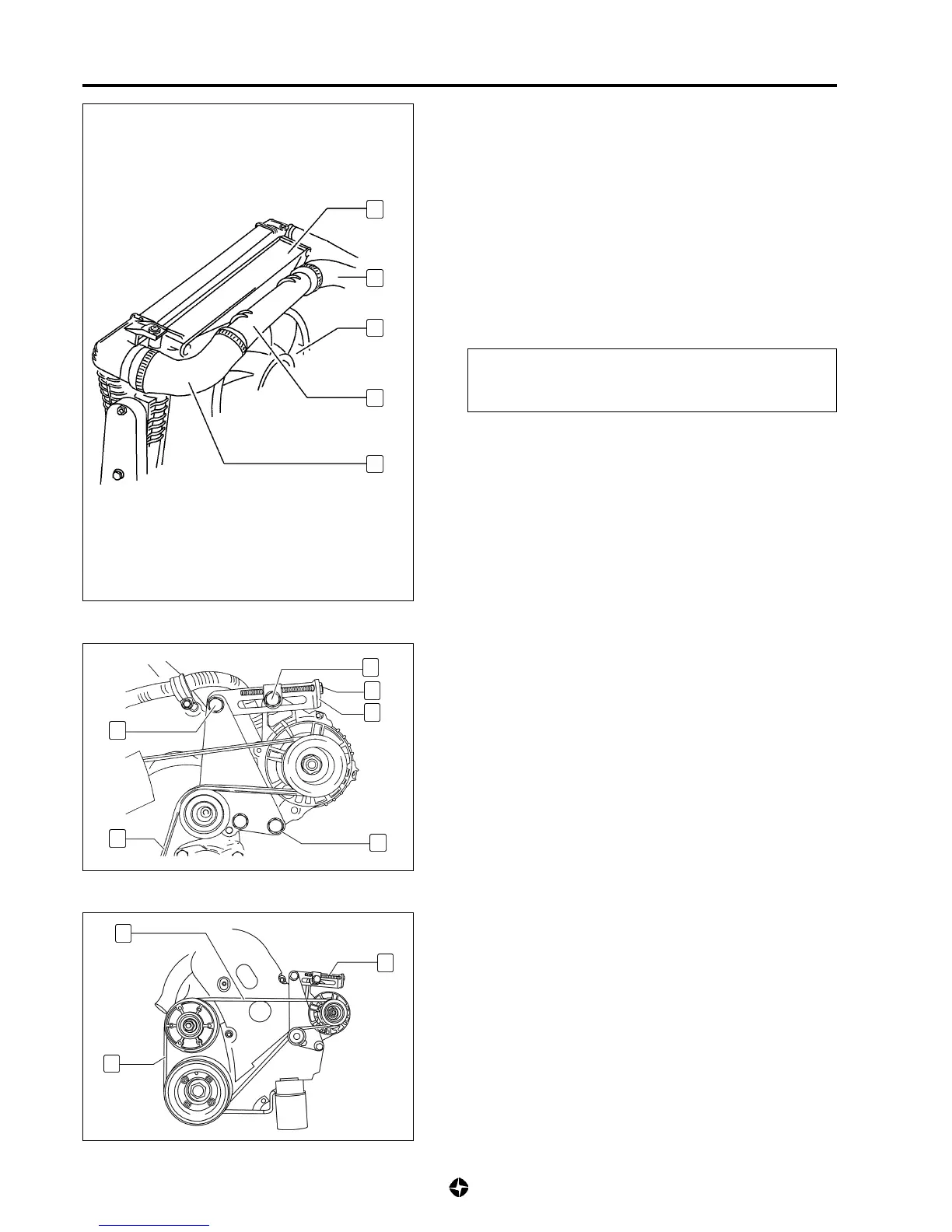

6) Loose screws or nuts (7), (8) and (11) by one turn to free

generator and tensor support (10).

7) Untaught belt (6) loosening regulating screw (9) and take it

away.

Installation

1) Put new belt (6) ensuring the correct path and coupling at

pulleys.

2) Taut slightly belt using screw (9); put back again previously

loosened screws and nuts, turn once the crankshaft and

check for correct coupling of belt.

3) Apply specified tension to belt and measure it on point (A)

(centre of course), using frequency meter ref. 00000A01484.

Frequency reading for generator and water pump belt

tension: 140 ± 5 Hz

8

9

10

11

6

7

A

6

9

Loading...

Loading...