ENGINE REPAIR 6A-27

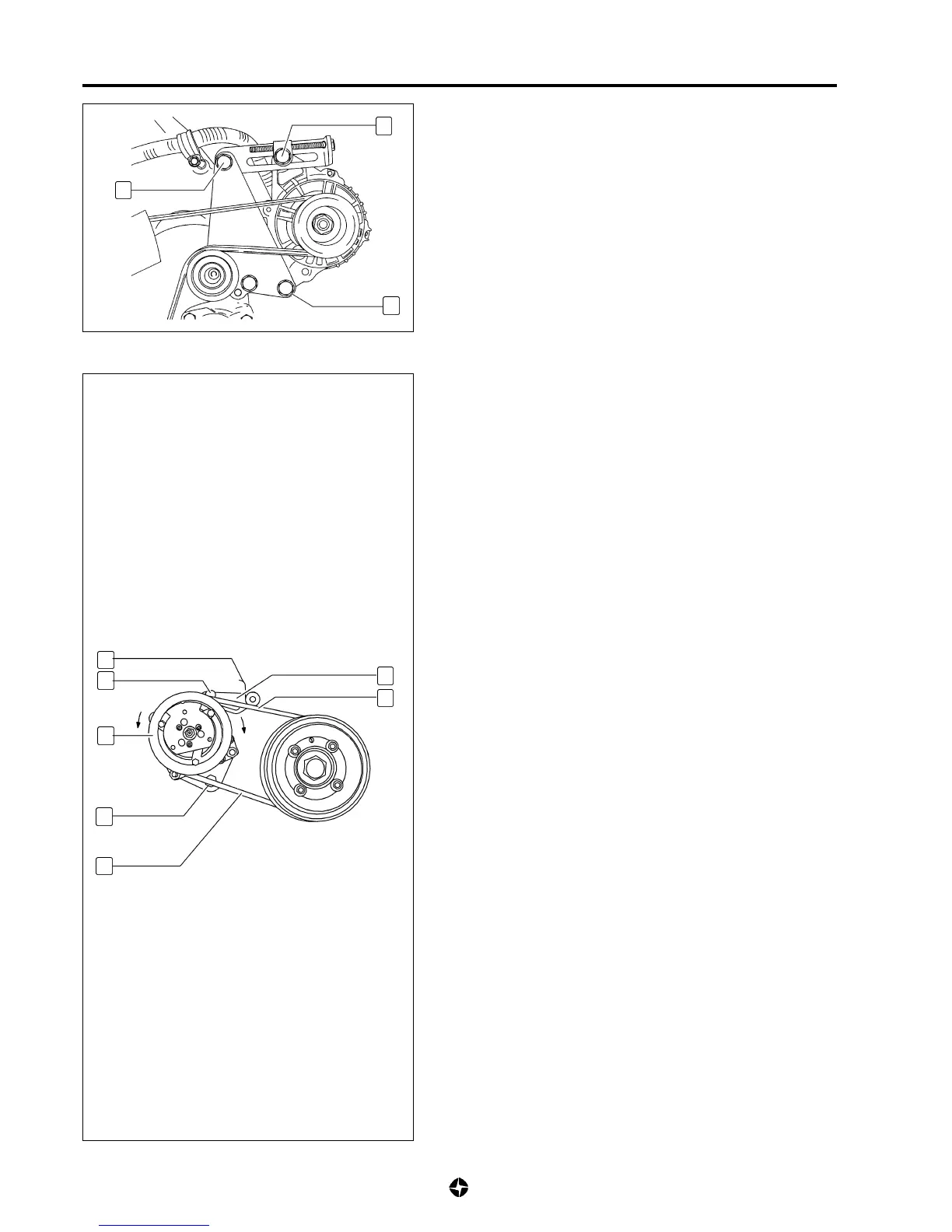

4) Tighten to the specified torque screws or nuts (11), (7) and

(8) which anchor the generator, the support and tensioning

block.

Tightening torque's:

• Screws or nuts (11) and (7):

5 Kg-m (50 Nm)

• Screw (8):

4,5 Kg-m (45 Nm)

5) Continue the installation reverse removal precedures; apply

to the fun the specified tightening torque.

Tightening torque for fan screws: 0,6 Kg-m (6 Nm)

7

11

8

Driving belt of Air Conditioning compressor (if

any) substitution

1) Remove generator driving belt and water pump (see 6A-26).

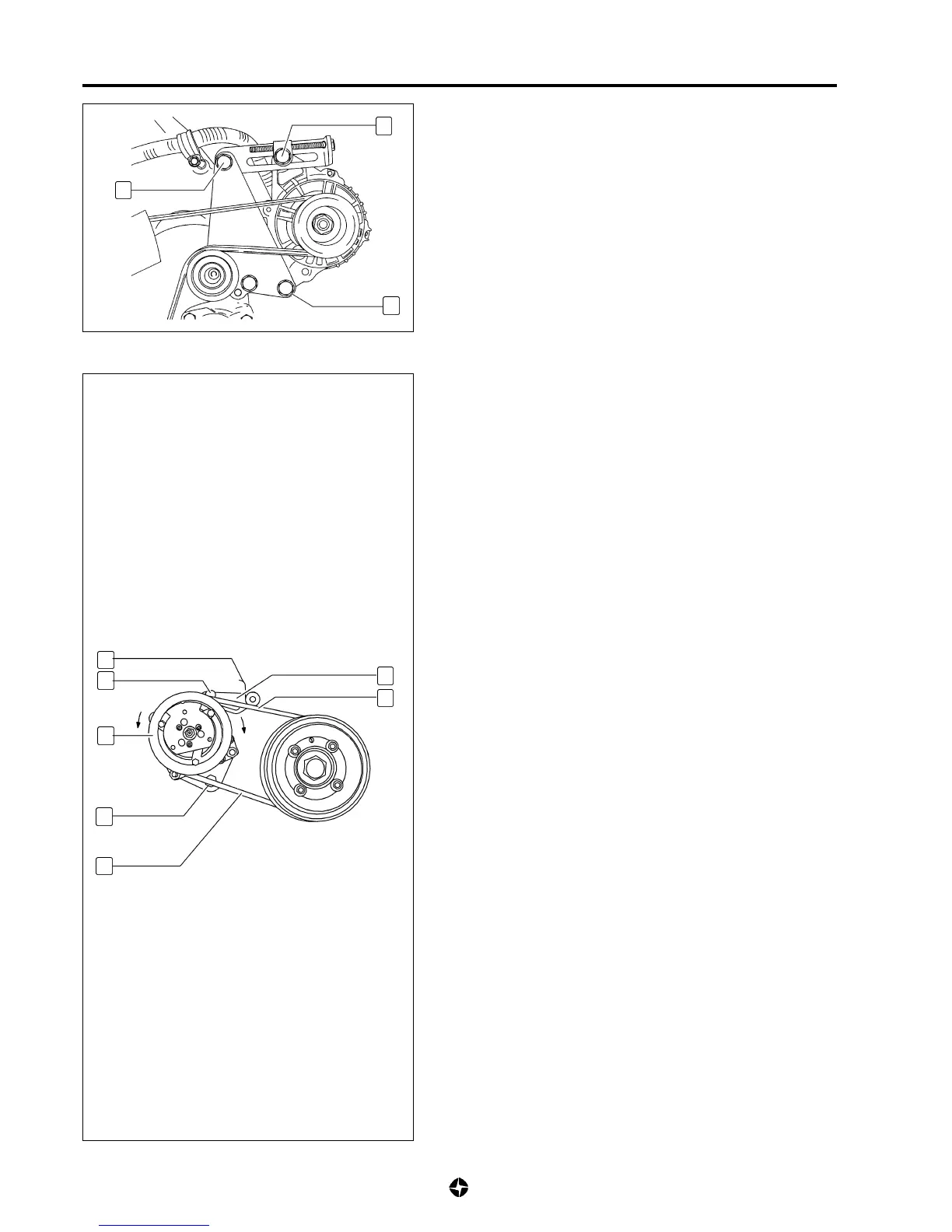

2) Loose by one turn the screws or nuts (12), (13) and (15) to

liberate the compressor (14) and tensioning adjustment fixing

lever (17).

3) Rotate the compressor towards the engine and withdraw

belt (16).

12

13

14

15

16

17

B

Installation

1) Install the new belt (16), ensuring the correct coupling in the

pulleys.

2) Tension slightly the belt rotating the compressor towards

outside, get tighter screws and nuts previously loosened;

turn crankshaft by one turn and check the coupling of belt.

3) Apply the specified tension to the belt and measure on point

(B) (centre of stretch), using frequency meter ref.

00000A01484.

Frequency reading for compressor belt tension:

160 ± 10 Hz

4) Tighten to specified torque nuts (12) and (13) and the screw

or nut (15).

Tightening torques:

• Nut (12) connecting tensioning adjustment fixing lever

to block: 4,5 Kg-m (45 Nm)

• Nut (13) connecting compressor to tensioning

adjustment fixing lever: 3,5 Kg-m (35 Nm)

• Screw or nut (15) connecting compressor support to

block: 4,5 Kg-m (45 Nm)

5) Continue installation reverse removal procedures; apply

specified tightening torque as indicated in complementary

tasks.

Loading...

Loading...