ENGINE FUEL AND EMISSION CONTROL SYSTEM 6C-9

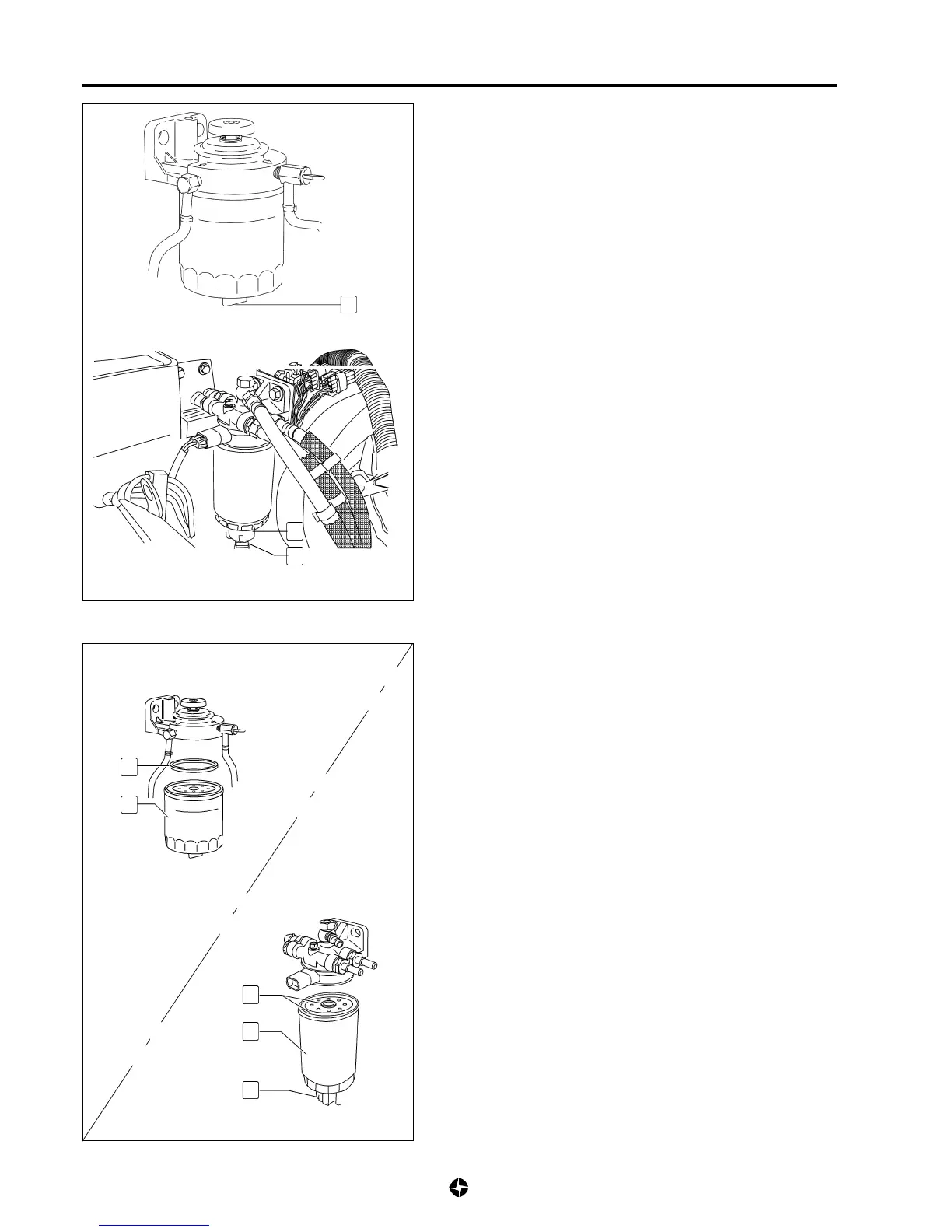

Water and residue cleaning from fuel filter

(mechanical injection engines)(mechanical injection engines)

(mechanical injection engines)(mechanical injection engines)

(mechanical injection engines)

• Open bleeder (3) and close when the fuel comes out clean

of residue or water.

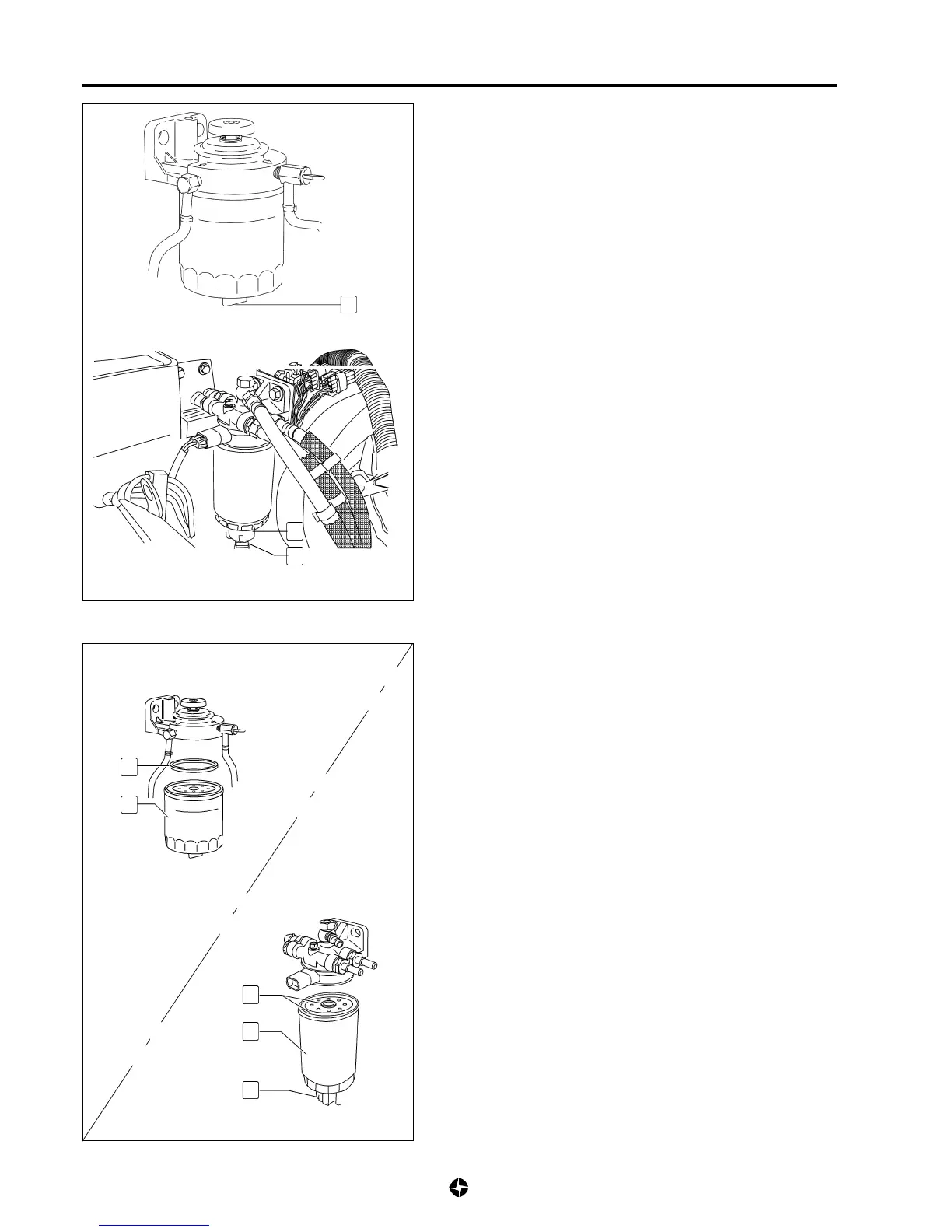

(Common Rail engines)(Common Rail engines)

(Common Rail engines)(Common Rail engines)

(Common Rail engines)

• Disconnect the coupler (7) from the water-in-fuel sensor

(8).

• Loosen the sensor (8) and tighten it slightly when the fuel

comes out of the sensor bleeder pipe free from residues or

water.

Fuel filter replacing

1) Remove the filter element (5) using a special filter key.

2) Install a new filter with the joint (4) correctly positioned and

tighten to the specified way.

(mechanical injection engines)(mechanical injection engines)

(mechanical injection engines)(mechanical injection engines)

(mechanical injection engines)

Fuel filter torque:

1,8 ÷ 2,8 Kg-m (18 ÷ 28 Nm)

• Bleed air as previously indicated. Start engine and check

there is no leakage.

(common rail engines)(common rail engines)

(common rail engines)(common rail engines)

(common rail engines)

• Transfer the water-in-fuel sensor (8) to the new filter

• Make sure that the joints (4) are touching by the support

and tighten 3/4 of a turn

3

FUEL FILTER (MECHANICAL INJECTION ENGINE)

FUEL FILTER (COMMON RAIL ENGINE)

7

8

4

5

4

5

8

FUEL FILTER (MECHANICAL INJECTION ENGINE)

FUEL FILTER (COMMON RAIL ENGINE)

Loading...

Loading...