5-20 BRAKES

VACUUM CIRCUIT CHECKING

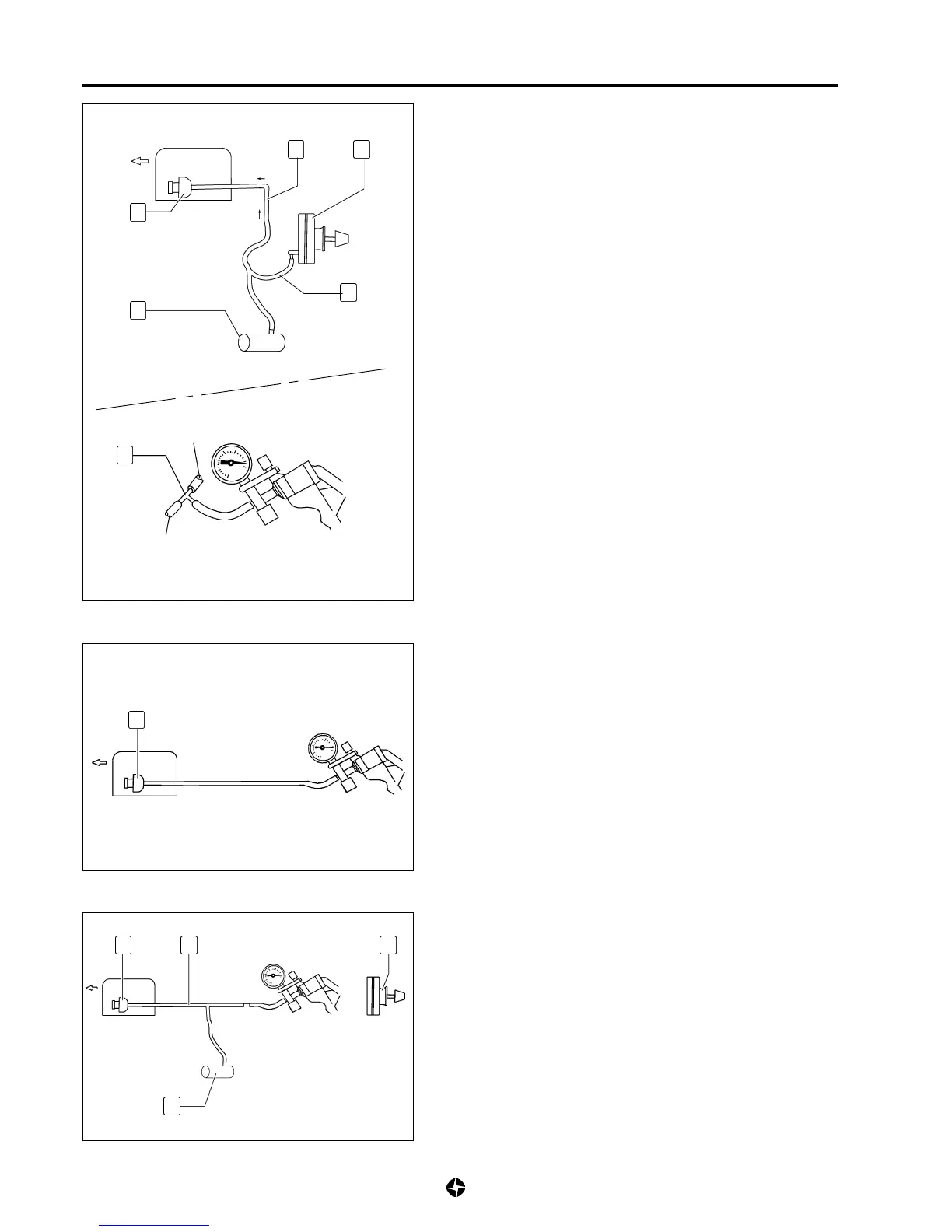

Circuit checking

1) Do a trial on road and verify that help towards breaking is

enough.

2) If help towards breaking is not satisfactory, disconnect sleeve

(2) from brake booster (3) connection and fix vacuum meter

in series point (A), as seen in the drawing.

3) With engine at 1000 rpm check if the press vacuum reading

is near to specified.

Vacuum pressure: 850 mbar

Otherwise, check:

• Eventual leaks through the vacuum sleeve (2).

• Eventual blockage of depressor exit (1) or breakdown in it.

• Eventual leaks in the brake booster (3).

• Eventual leaks in the vacuum tank (4).

Locating leaks and breakdowns

4) Connect a vacuum meter to vacuum pump and carry out

checking as explained in task -3-.

4

1

2 3

A

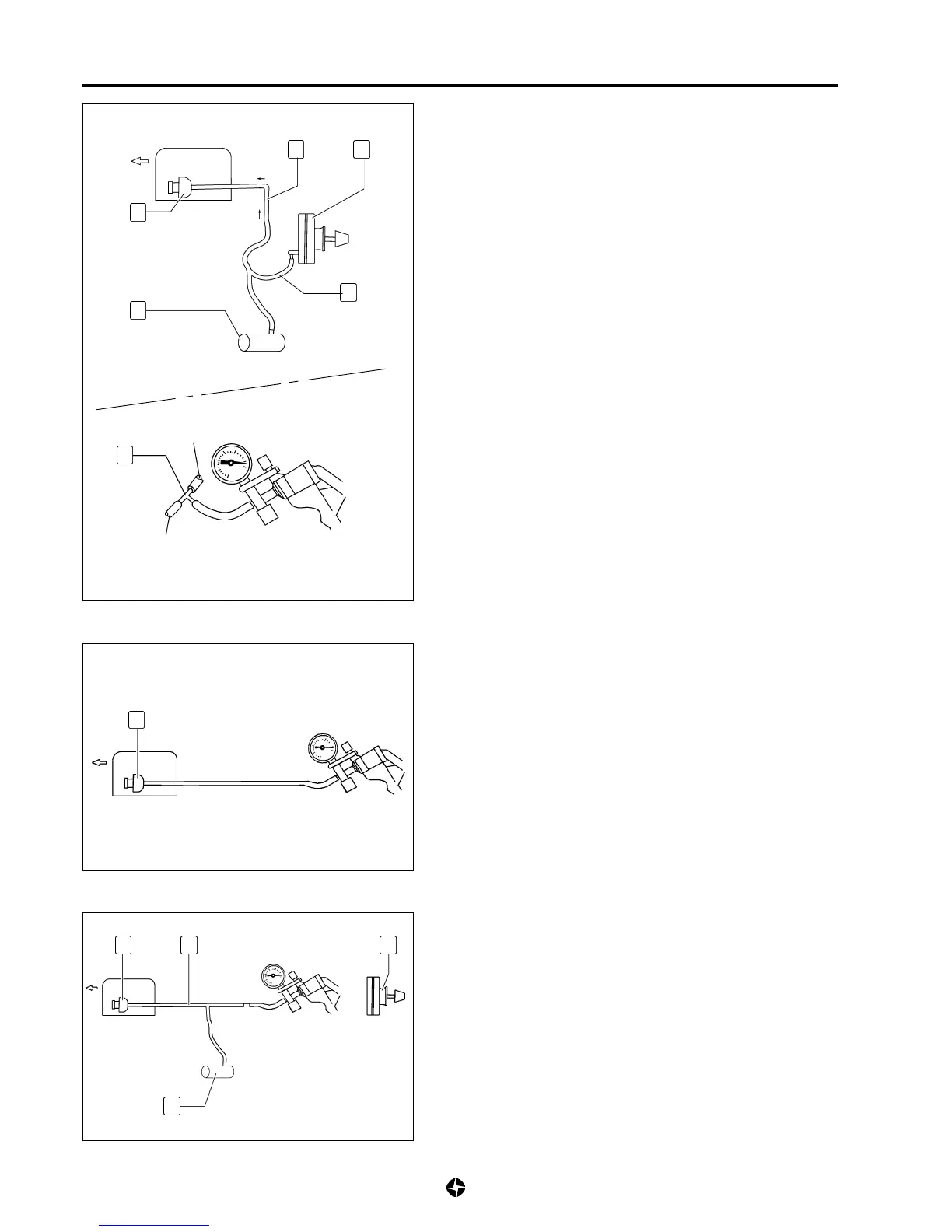

5) If it is no correct, the depressor is faulty. If it is right then do

as follows:

• Connect vacuum sleeve (2) to depressor (1).

• Disconnect sleeve (2) from connection to brake booster

(3) and fit the vacuum meter at free end.

• Carry out checking as explained in task -3-.

1

1

2

4

3

TO BRAKES BOOSTER

TO DEPRESSOR

AND VACUUM TANK

ENGINE

FRONT

A

Loading...

Loading...