5-34 BRAKES

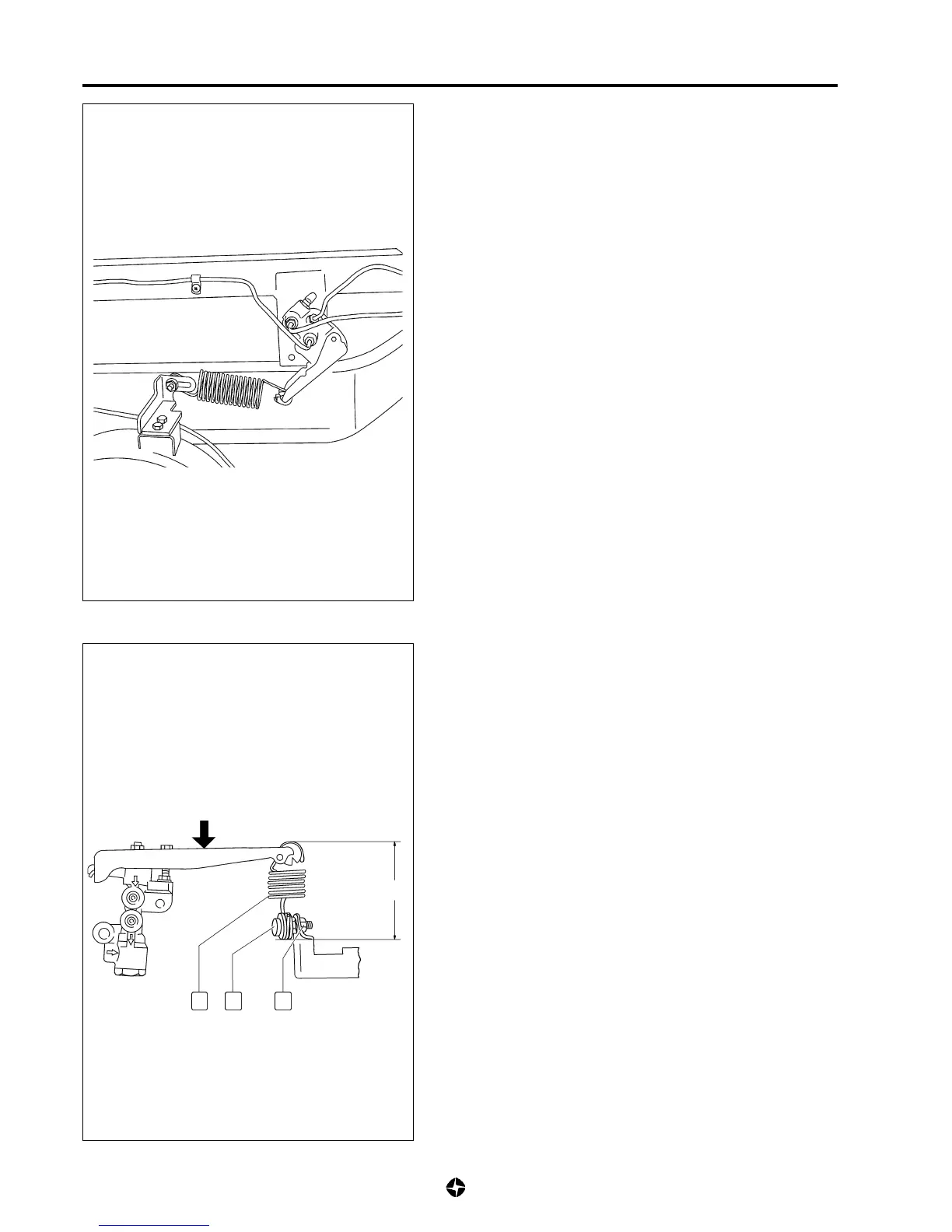

Adjustments

NOTE:

Before adjustment and inspection check before hand

the followings points:

• Fuel tank is full,

• Spare wheel, tools, and jack and its crank are on the

vehicle.

• The vehicle has no other type of loading.

1) Place the vehicle on levelled ground.

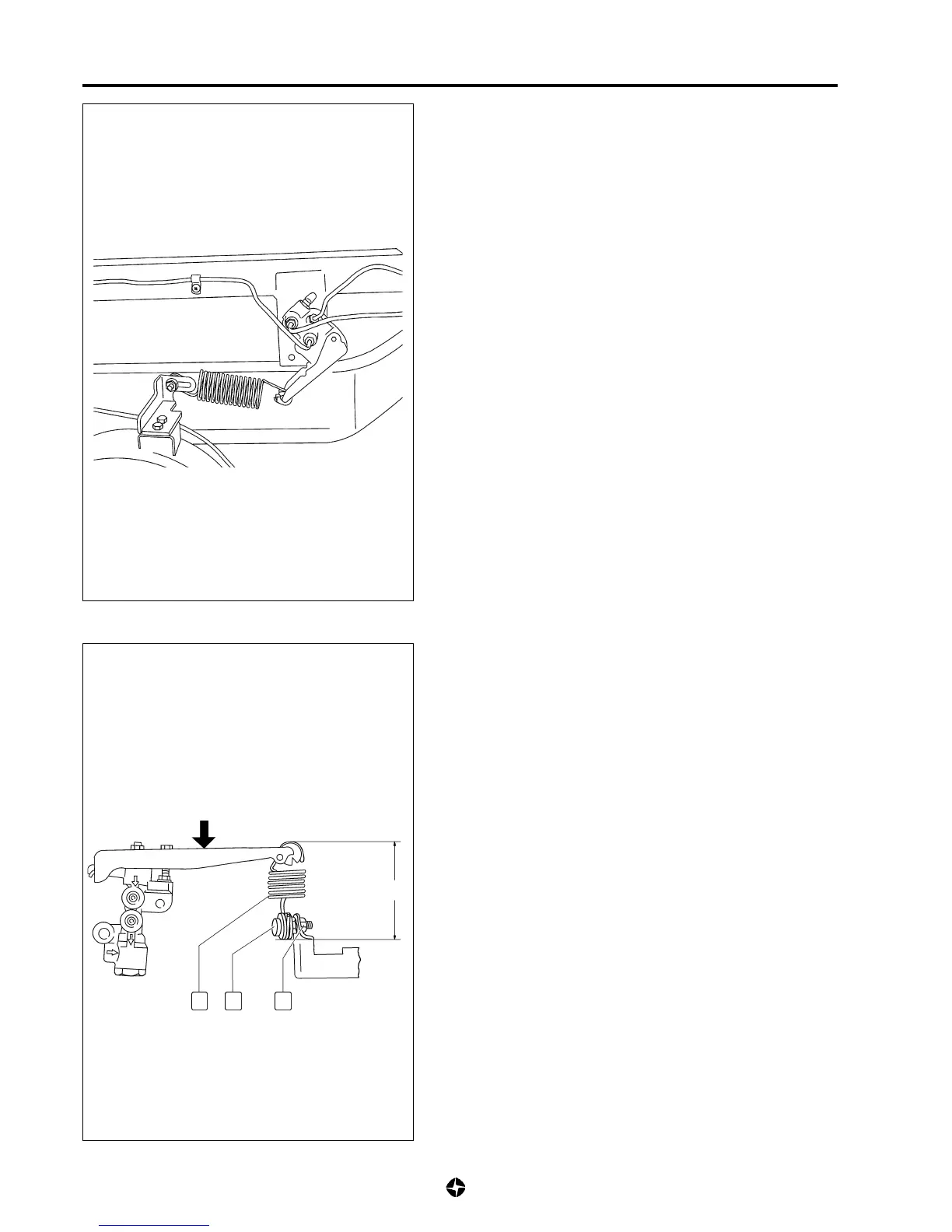

2) Push LSPV lever with the finger till contact of to screw and

measure length (L) of the helicoidal spring (3) which must

correspond with the specified value.

Spring length (L): 150 ± 1 mm

3) If the spring length (L) is different than this value then adjust

length (L) turning eccentrically head of screw (5); tighten

afterwards nut (6) to specified tightening torque.

Tightening torque for nut fixing adjustment:

1,8 ÷ 2,8 Kg-m (18 ÷ 28 N m)

NOTE:

Check to make sure that LSPV body and brake pipes

are free form fluid leakage. Replace defective parts, if

any.

Tightening torques:

• Screws fixing valve LSPV:

1,8 ÷ 2,8 Kg-m (18 ÷ 28 N m)

• Fixing screws of support:

1,8 ÷ 2,8 Kg-m (18 ÷ 28 N m)

• Purger:

1 ÷1,3 Kg-m (10 ÷ 13 Nm)

• Linkages fixing brake pipes:

1,4÷ 1,8 Kg-m (14÷ 18 Nm)

2) Fill tank with the recommended fluid and purge air from the

brake system (see 5-17).

NOTE:

Make sure to purgue air form LSPV purguer without

fail

3) Check, after purging, if LSPV is properly installated and

adjusted.

L

3 5 6

Loading...

Loading...