ENGINE REPAIR 6A-29

Installation

NOTE:

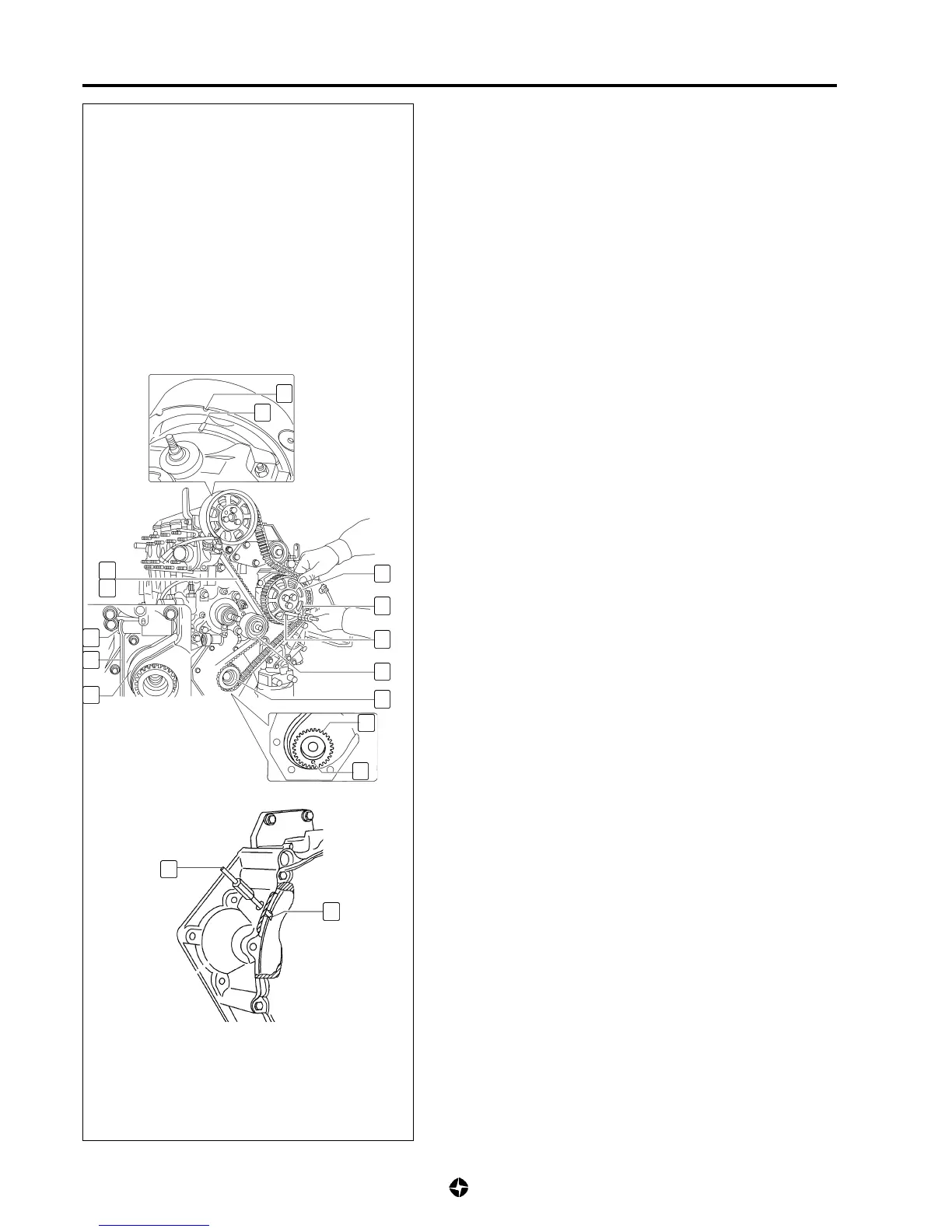

• Remember that the three control points must be

synchronised as explained under dismantling task (5

th

).

In other words, mark (A) from camshaft gear and mark

(B) of plungers cover must be aligned; tool (C1) lodged

into synchronisation position of gear (24) (holes

aligned); tool (C) lodged into synchronisation position

of flywheel (21).

• Notice that hole (36) of crankshaft gear (35) looks

downwards (warranty of T.D.C. piston n° 1).

1) Install new timing belt (28), ensuring the correct coupling in

teeth of gears and of the correct tensioning of both stretches,

which do not require a later tensioning adjustment.

2) Withdraw key (31) to allow beam (30) acts over the tensor

roller (32) and put belt under tension.

3) Withdraw tools (C) to synchronise gear (24) and flywheel

(21). Turn crankshaft two complete turns till aligning marks

(A) and (B).

In this position, check again the synchronisation between

gear (24) and flywheel (21) using tools (C) ref. 790965.

NOTE:

If these conditions are not fulfilled, do a new setting of

the timing belt.

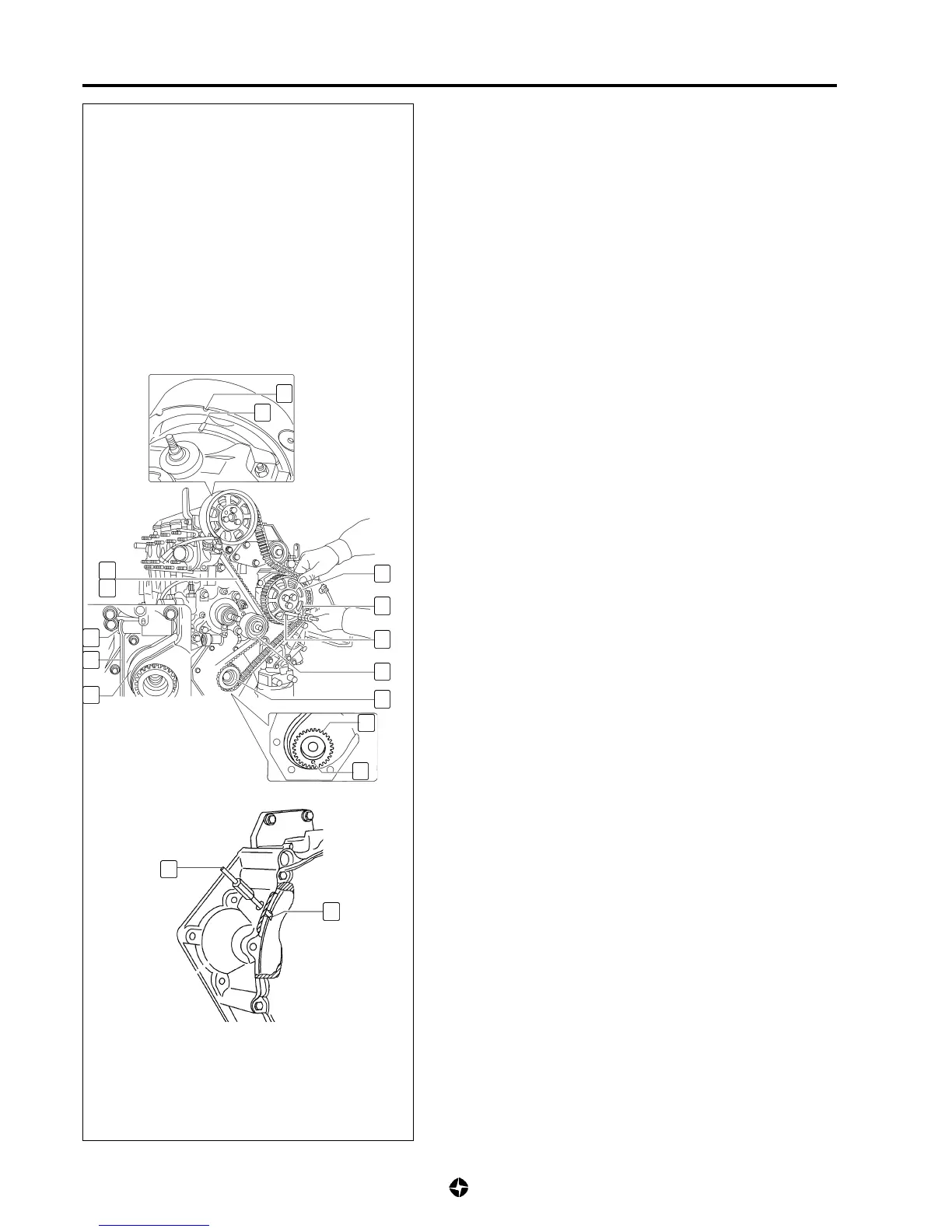

4) Install timing lower cover (26); tighten screws to the specified

tightening torque.

Tightening torque of timing lower cover screw:

0,75 Kg-m (7,5 Nm)

Timing belt tension checking

5) Apply torque of 2.8 ÷ 3.0 Kg m to crankshaft (34) in the

rotating direction, to put belt slightly tensioned.

6) Install nut and washers fixing tensioning roller (32) and apply

the specified tightening torque.

Tightening torque at belt tensioning roller nut:

4 Kg-m (40 Nm)

7) Check that belt tension at point (D) agrees with the specified

value.

Value of HSN (High Strength Nitrile) belt, measured in

point (D) with frequency meter ref. 00000A01484 must

be 88 ÷ 112 Hz

8) Complete Installation reverse removal procedures. Apply the

specified tightening torque's and those indicated in the

complementary tasks.

Tightening torques:

• Screws at cover of timing: 0,75 Kg-m (7,5 Nm)

• Screw of the crankshaft pulley: 20 Kg-m (200 Nm)

• Nuts of the sound proofing upper cover: 0,5 Kg-m (5

Nm)

A

B

24

C

1

25

32

34

35

36

30

31

26

28

D

C

21

Loading...

Loading...