6A-38 ENGINE REPAIR

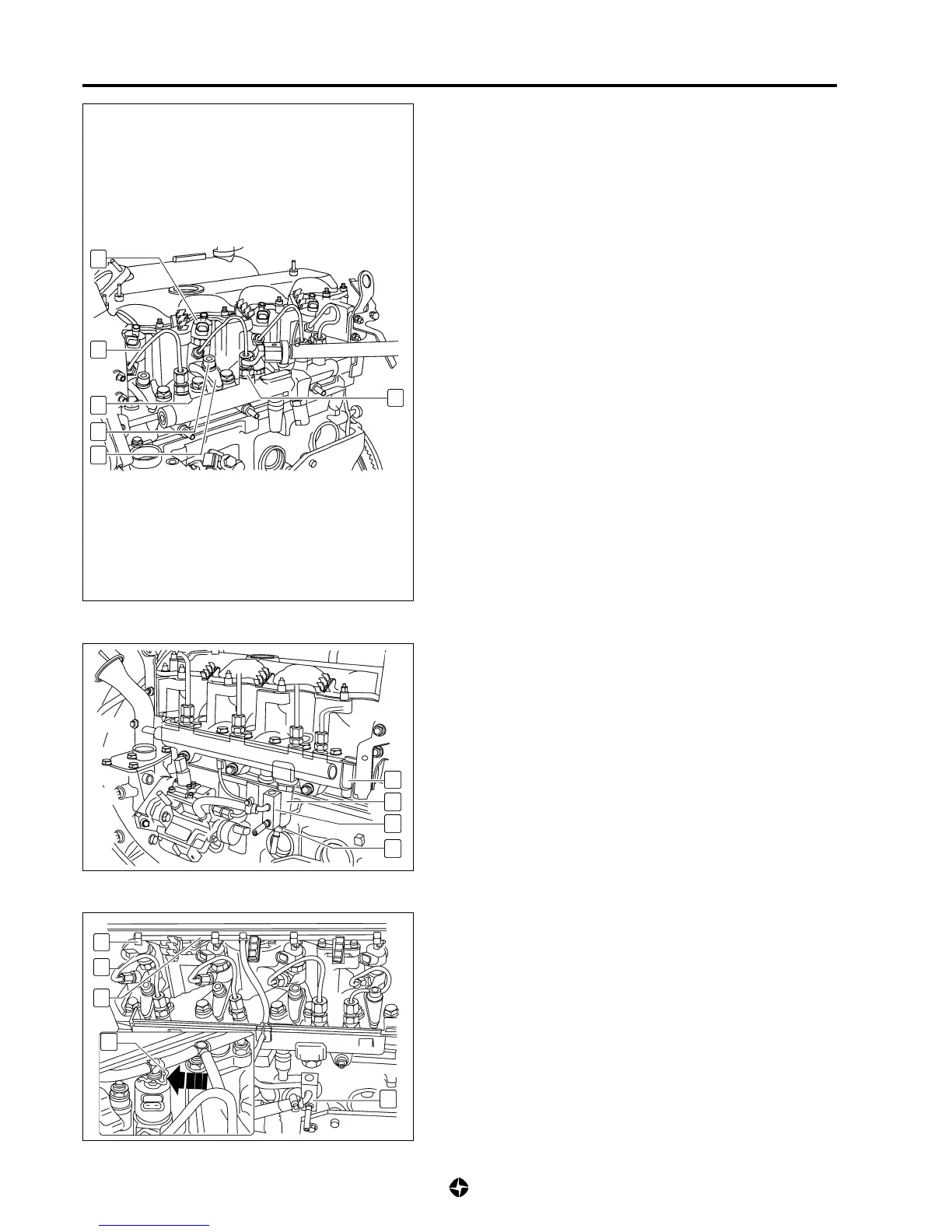

4) Install injector (8) using clamps (14) and bolts (13),

tightenedan specified torque

Tightening torque injectors clamps nuts:

4 kg-m (40 Nm)

5) Connect hihg pressure pipes (9) to injectors (8) and hydraulic

accumulator (23). Tighten union nuts at specified torque,

holding how limiters to avoid rotation.

Tightening torques:

• Union nuts, rail outlet pipes:

2 kg-m (20 Nm)

• Union nuts, injectors fuel inlet pipes:

2 kg-m (20 Nm)

NOTE:

If any repair is required on injectors high pressure pipes,

replace it as assembly.

6) Install rail soundproof cover (15) and multiple connector (21),

fixed by union nut (22) at valve (26). Tighten at specified

torque:

Tightening torques:

• Rail soundproof cover nuts:

1,8 kg-m (18 Nm)

• Return multiple connector union nuts:

2,7 kg-m (27 Nm)

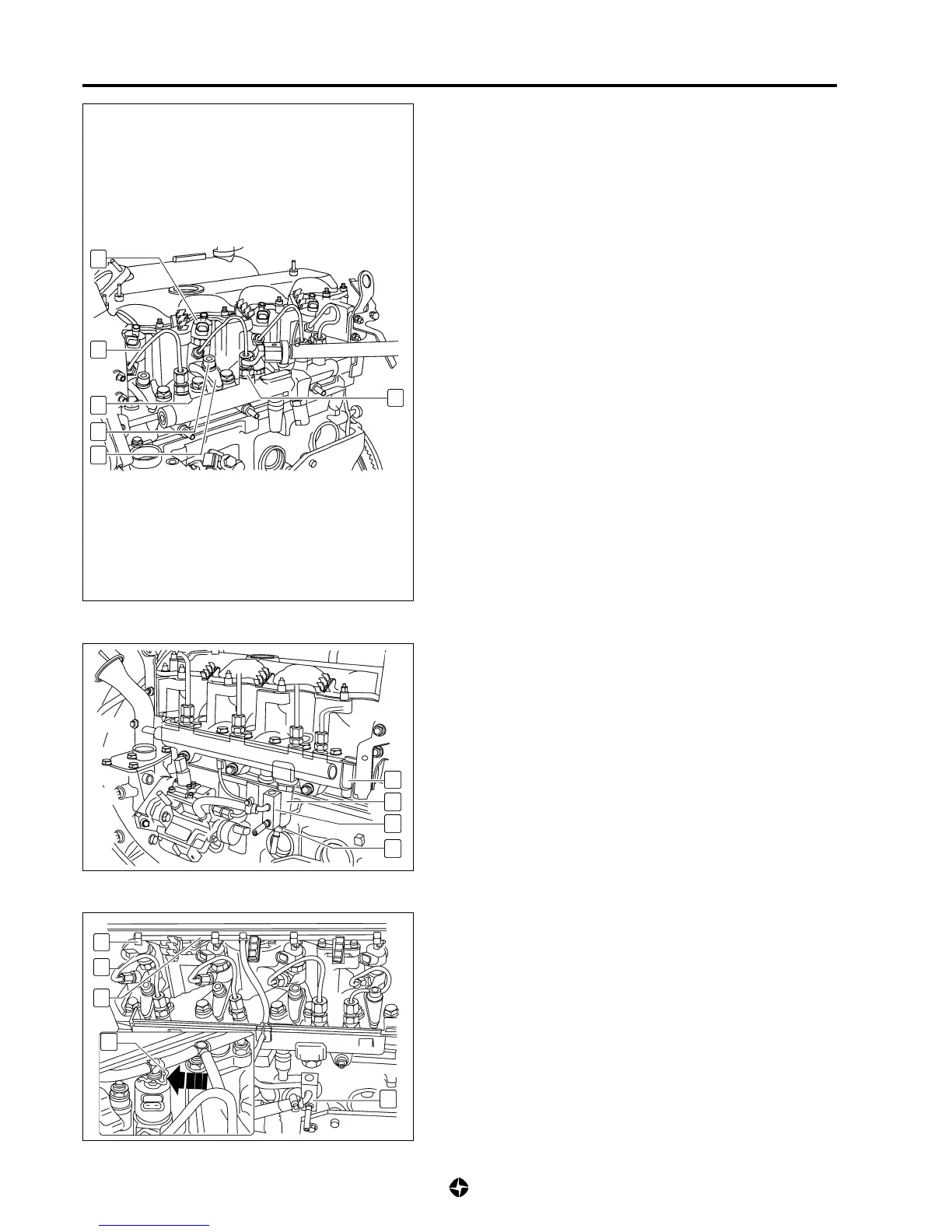

7) Install pump return pipe (16).

8) Connect return pipe (6) to multiple connector (29) and

injectors (8) pressing on clamp (4) towards arrow direction

(see figure).

9) Go on with installation, by reversing removal procedure,

noting to tighten at specified torque.

12

23

13

14

9

8

15

26

21

22

6

8

4

4

21

Loading...

Loading...