6A-84 ENGINE REPAIR

ENGINE REPAIR ON THE WORK BENCH

NOTE:

While repairing the engine on the work bench, we will no

go deep down into those tasks described in "REPAIRS ON

VEHICLE", and basically identical to the ones in "ENGINE

REPAIR ON THE WORK BENCH".

PREPARING THE ENGINE TO BE PUT ON THE

WORK BENCH

NOTE:

To fit the bridles ref. 790989 fixing the engine to the work

bench is necessary to remove the components described

below.

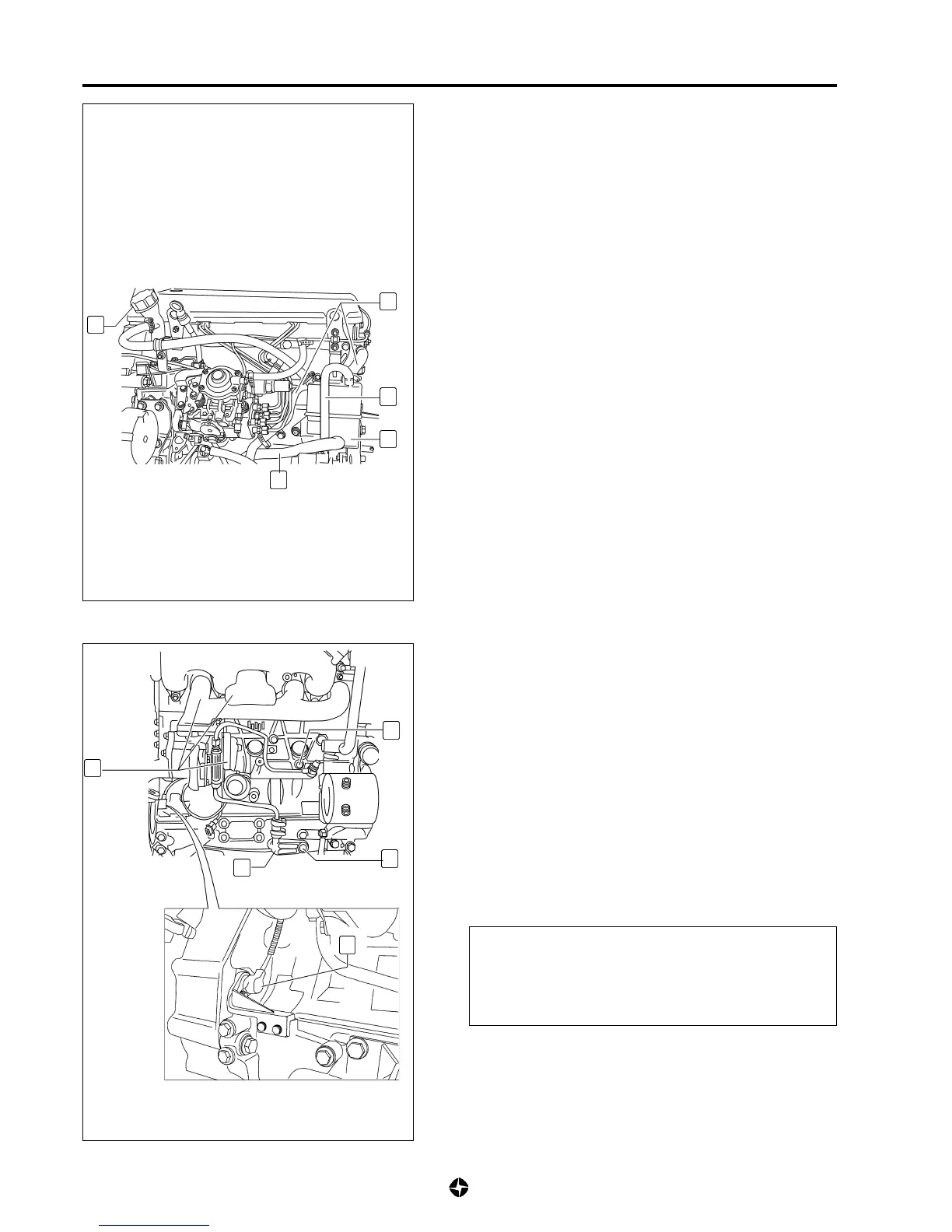

1) At the left side of engine, remove:

• Ensemble ofhoses and water outlet tube (2) of the heat

exchanger.

• Oil system spout and hose of vapours recycling (1), hose

for discharge to the atmosphere of excess vapours (3), oil

vapours condenser (4) and oil recycling hose (5) .

1

4

2

5

6

9

8

7

CAUTION:

Cap adequately air and gas inlets and outlets of

turbocharger as well as the oil ducts. The entry of

alien bodies in the conductions will very seriously

damage the turbo charger.

3) Fit to engine flange or bridle ref. 790989 and fix the ensem-

ble to rotating work bench ref. 790990.

3

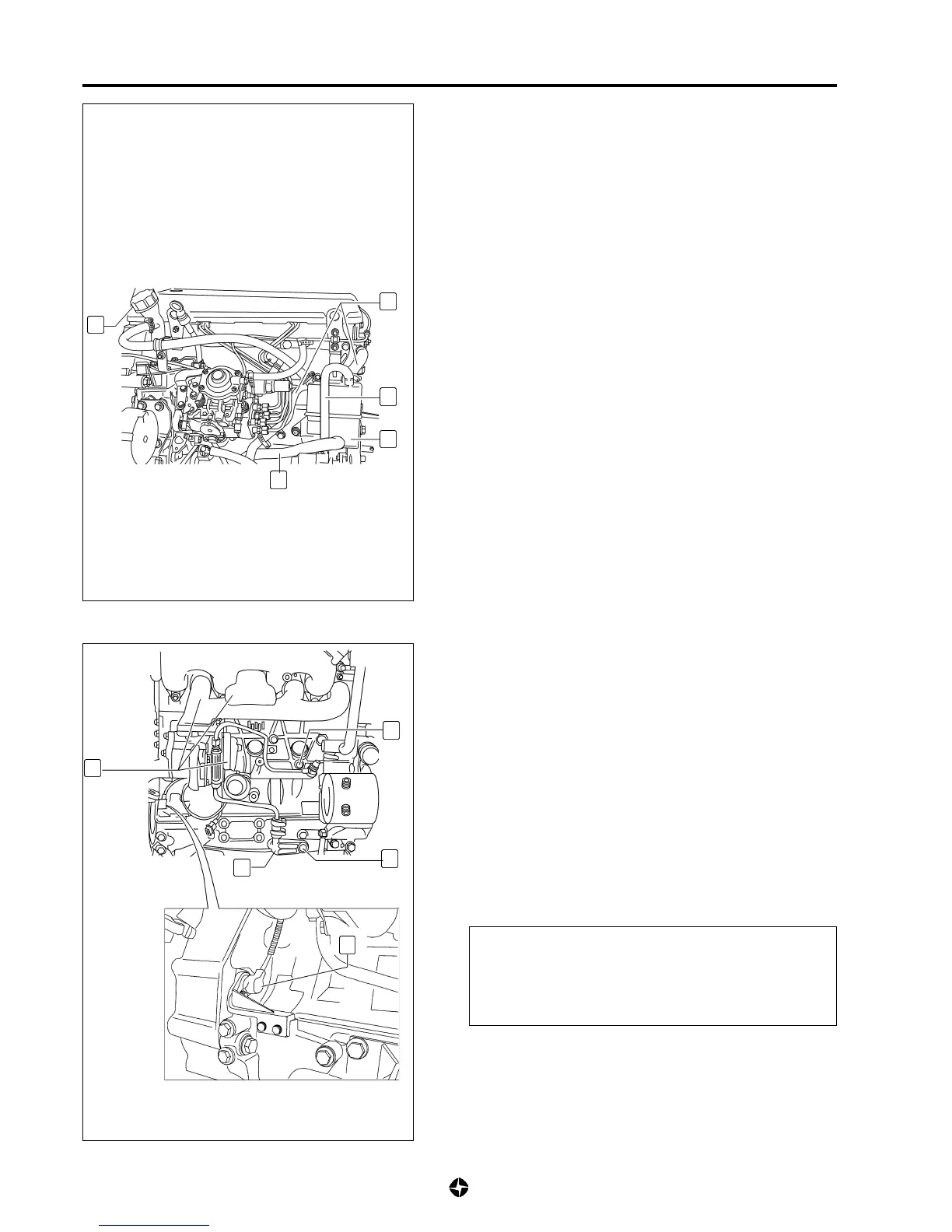

2) At the right side of engine, remove:

• Assembly turbocharger, exhaust manifold and thermal

screen (6) (see 6A-62).

• Threaded cap (7) (if available)

• Screw (9) and adaptor (8) for draining pipe.

• Rev sensor (78) and its support

(common rail(common rail

(common rail(common rail

(common rail

engine).engine).

engine).engine).

engine).

78

Loading...

Loading...