18 Maintenance and Inspection

18.9 Inspection and Maintenance: FID

305

GC-2010 Plus

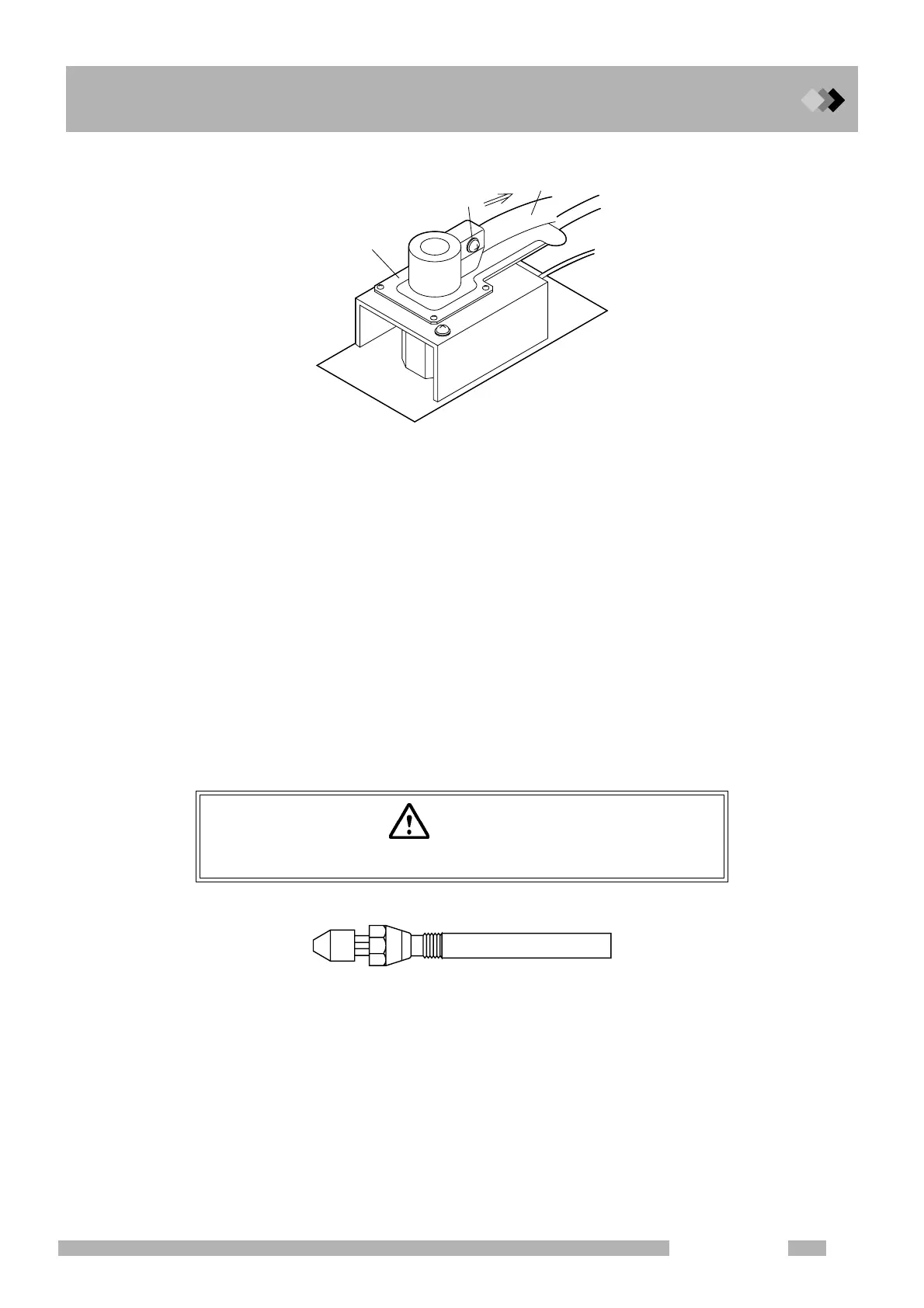

Fig. 18.9.1

b) Replacement and inspection of the FID jet are described below.

Q Troubleshooting

(1) Checking whether the jet is clogged

If the jet is clogged, ignition may be difficult or peaks may not be detected.

If the tip of the jet is clogged, clean the jet by inserting a slender, long wire into the tip.

(2) Checking whether the jet is dirty

If the jet is dirty, noise may be significant.

If the jet is dirty, wipe off dirt with a cotton swab soaked in organic solvent (such as

acetone), etc.

(3) Checking whether the jet is damaged

If the jet is damaged, the peak shape may be abnormal.

Replace the jet.

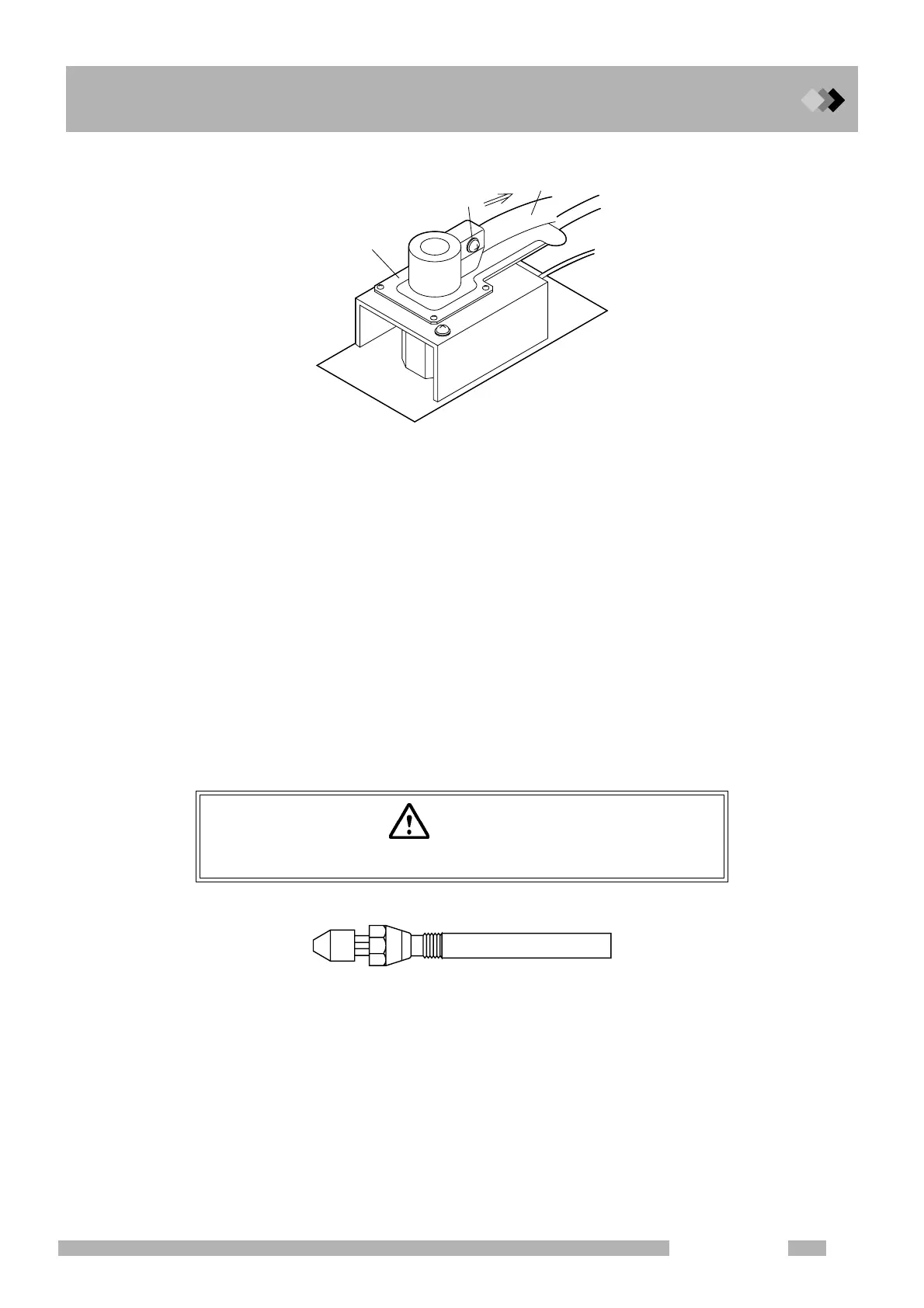

Fig. 18.9.2

Chack the type of Jet, because there are some different types of jet.

Q Preparing the gas chromatograph

If the system is operating, press the [SYSTEM] key and select [Stop GC] (PF menu). The

temperature of the injection port , the column oven and detector automatically decreases.

Press the [MONIT] key, and ensure that the temperature of the injection port, the detector

and the column oven has dropped below 50 °C.

Press the [FLOW] key, and select [Off] (PF menu). The inspection/maintenance can begin.

CAUTION

The quartz FID jet can be broken easily. Treat it gently.

Igniter screw

Collector

Igniter

Loading...

Loading...